Steel wire net frame composite outer wall heat insulating plate

A technology of external wall insulation board and steel wire grid, which is applied in the direction of insulation, walls, building components, etc., can solve the problems of weak penetration fastening force, poor penetration fastening force, water seepage of the external wall, etc., and achieve shear resistance Strong, strong penetrating fastening force, good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

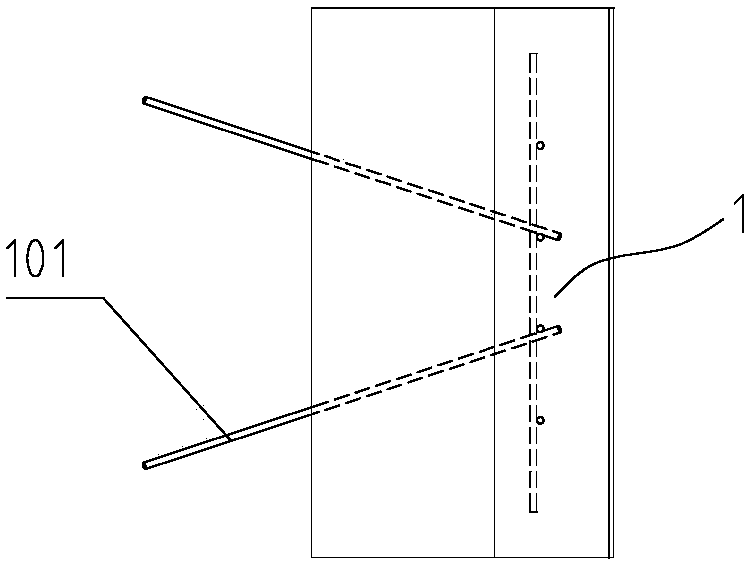

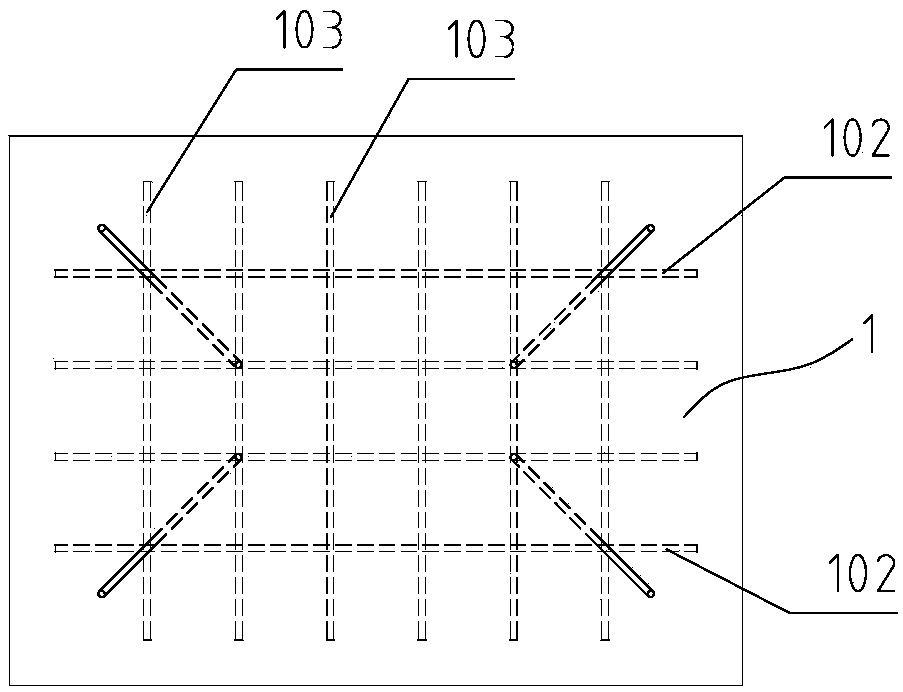

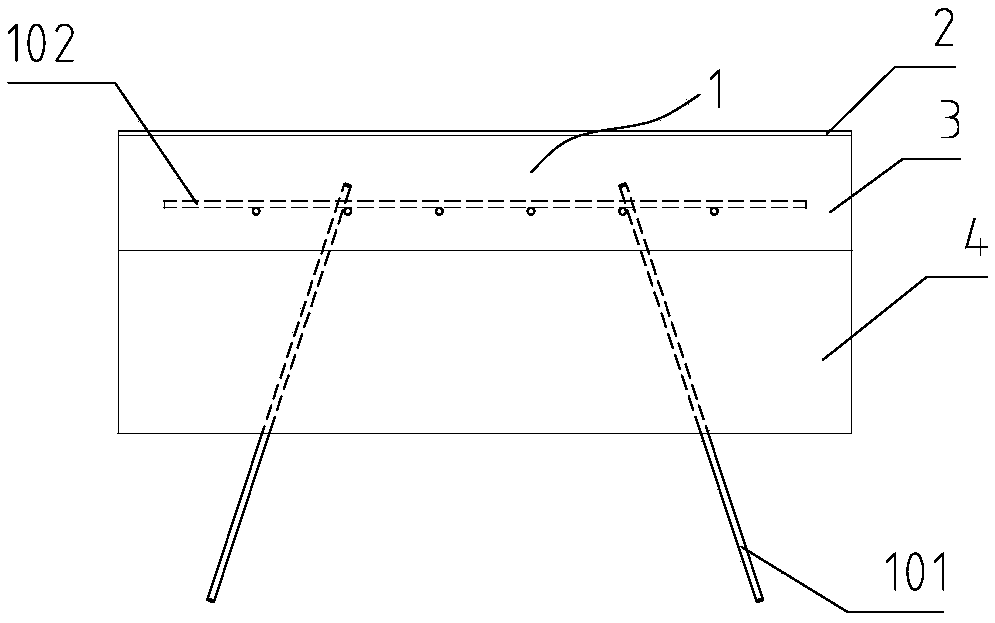

[0061] Figure 1-Figure 8 It is an embodiment of the present invention, a steel wire grid composite exterior wall insulation board, provided with an insulation layer 4, a concrete layer 3 is provided on one side of the insulation layer 4, and a steel wire mesh is installed inside the insulation layer 4 and the concrete layer 3 Support frame 1, steel wire mesh support frame 1 comprises horizontal support steel wire 102 and longitudinal support steel wire 103, and horizontal support steel wire 102 and longitudinal support steel wire 103 are interlacedly connected, and steel wire mesh support frame 1 is also provided with support leg 101, and support leg 101 one end is connected with horizontal The supporting steel wires 102 or the longitudinal supporting steel wires 103 are overlapped and connected, and the cross-connected horizontal supporting steel wires 102 and longitudinal supporting steel wires 103 are located inside the concrete layer 3, and the other ends of the supporting...

Embodiment 2

[0074] Figure 9-Figure 16 It is another embodiment of a steel wire grid composite exterior wall thermal insulation board of the present invention. The difference from Embodiment 1 is that the horizontal support steel wires 102 and vertical support steel wires 103 that are intertwined on the steel wire mesh support frame 1 are two upper and lower layers. The horizontal support steel wires 102 and the vertical support steel wires 103 of the upper and lower layers interlaced are located in the concrete layer 3 of the steel wire grid composite exterior wall insulation board, and the horizontal support steel wires 102 and the longitudinal support steel wires 103 of the upper and lower layers are intertwined with the concrete layer 3 Embedded with each other to form a tight adhesion, so that the concrete layer 3 with the upper and lower layers of horizontal support steel wires 102 and longitudinal support steel wires 103 intertwined has a stronger load-bearing capacity and stronger ...

Embodiment 3

[0078] Figure 17-Figure 24 It is another embodiment of a steel wire grid composite exterior wall insulation board of the present invention. The difference from Embodiment 1 and Embodiment 2 is that the horizontal support steel wires 102 and longitudinal support steel wires 103 are interlaced on the steel wire mesh support frame 1 Among them, the horizontal support steel wire 102 is bent up and down, and when the horizontal support steel wire 102 bent up and down runs through the concrete layer 3 of the steel wire grid composite external wall insulation board, the length of the horizontal support steel wire 102 bent up and down is lengthened. The up and down bending design of the horizontal support steel wire 102 can evenly support the concrete layer 3 of the steel wire grid composite exterior wall insulation board, so that the support force received by the concrete layer 3 supporting the steel wire grid composite exterior wall insulation board is even. The grid composite exte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com