Integral type grading bearing mechanism

A load-carrying mechanism and integrated technology, applied in the direction of elastic suspension, vehicle parts, transportation and packaging, etc., can solve the problems of inability to distribute pressure and low service life of the drive system, and achieve good stiffness, excellent performance and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

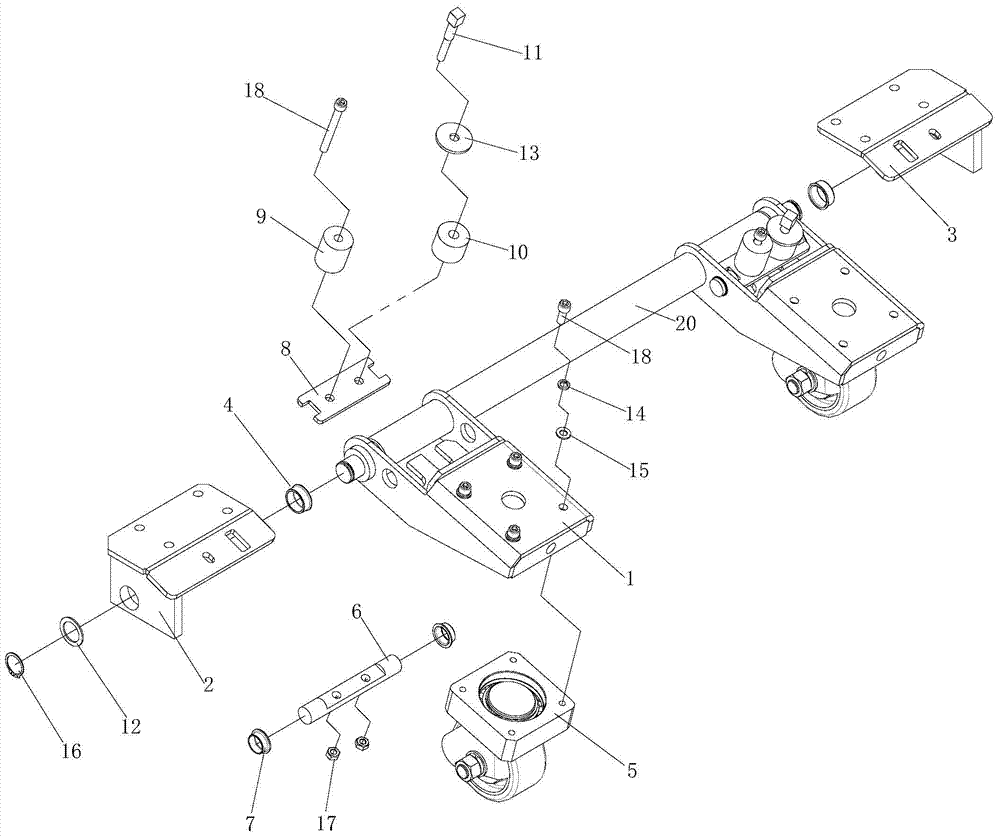

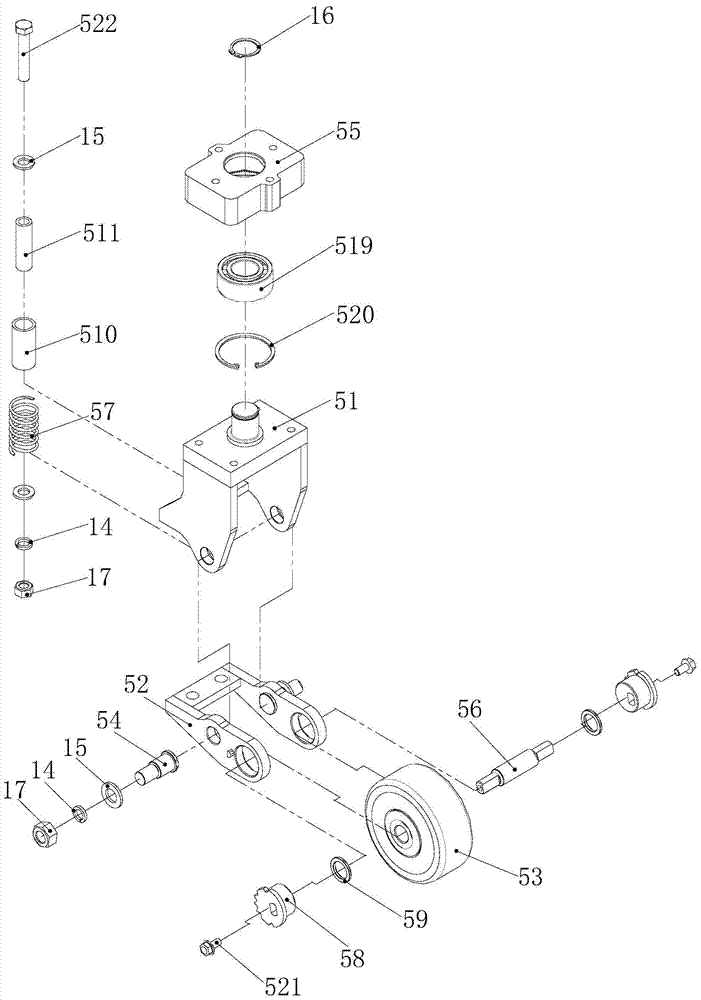

[0015] refer to figure 1 , figure 2 , an integral graded bearing mechanism of the present invention, comprising a connecting rod 20, a bracket 1, a left bearing plate 2, a right bearing plate 3 and a wheel assembly 5, and a bracket 1 is installed at both ends of the connecting rod 20 , the left bearing plate 2 and the right bearing plate 3 are installed on the left and right sides of the connecting rod 20, the connecting shaft 6 is installed on the support 1, the spring seat 8 is installed on the connecting shaft 6, and the spring seat The first primary shock absorbing spring 9 and the first secondary shock absorbing spring 10 are installed, and the wheel assembly 5 is installed on the bottom of the support 1, and the wheel assembly 5 includes a mounting frame 51, a wheel frame 52, a roller 53, Mounting seat 55, axle 56, guide sleeve 510, second primary shock absorbing spring 57 and second secondary shock absorbing spring 511, described mounting frame 51 is installed on whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com