Microwave heatable bowl cover film with good planeness and preparation method thereof

A microwave heating and flatness technology, applied in chemical instruments and methods, sustainable manufacturing/processing, flexible coverings, etc. Heat sealing performance, good stiffness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

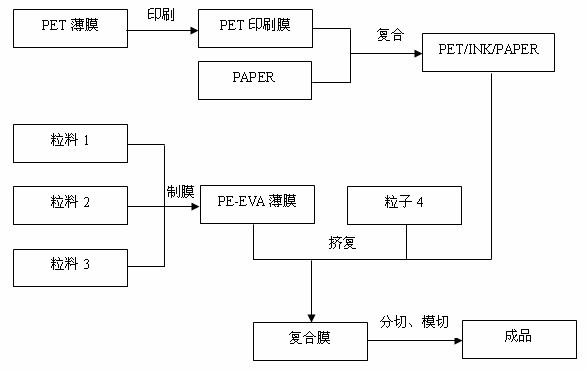

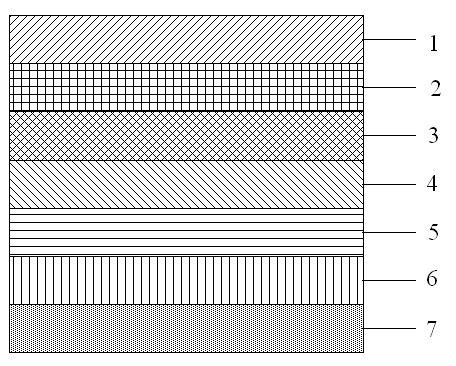

[0042] a. Polyethylene terephthalate (PET) layer printing process: at 50°C, color printing the PET film to form a PET printing film;

[0043] b. The preparation process of the composite polyethylene-vinyl acetate (PE-EVA) layer: each layer of polyethylene resin and ethylene-vinyl acetate resin are placed in their respective barrels according to the proportions, and after being extruded by an extruder, Make composite polyethylene-vinyl acetate film.

[0044] c. Dry lamination: Glue the PET printed film that has been printed with patterns and text, and lamination with PAPER90G through a dry lamination machine. The glue used is polyurethane glue, and the operating concentration of the adhesive is controlled at No. 3 Zahn Cup 16-17 Seconds, the coating amount is 2.5-3.3gsm, the composite tension is controlled at 28%, and the humidity is adjusted at 40%-50%.

[0045] d. Extrusion compounding: PE is extruded between the paper surface of the PET / INK / PAPER semi-finished product and the PE-E...

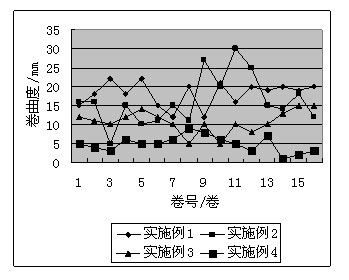

Embodiment 2

[0049] Except c. Dry compounding: the compound tension is controlled at 40%; d. Extrusion compounding: the second PE tension setting is 0.1kgf. The rest is the same as in Example 1.

Embodiment 3

[0050] Example 3: In addition to c, dry compounding: the compounding tension is controlled at 35%; d, extrusion compounding: the second PE tension is set to 0.3kgf. The rest is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com