Right box of bi-gear gearbox assembly of electric vehicle

A technology of electric vehicle and right box, which is applied in the direction of transmission box, transmission parts, components with teeth, etc. It can solve the problems of inability to adjust, inability to change speed, poor adaptability to road conditions, etc., and achieves convenient material acquisition, compact structure, Good combination of rigidity and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

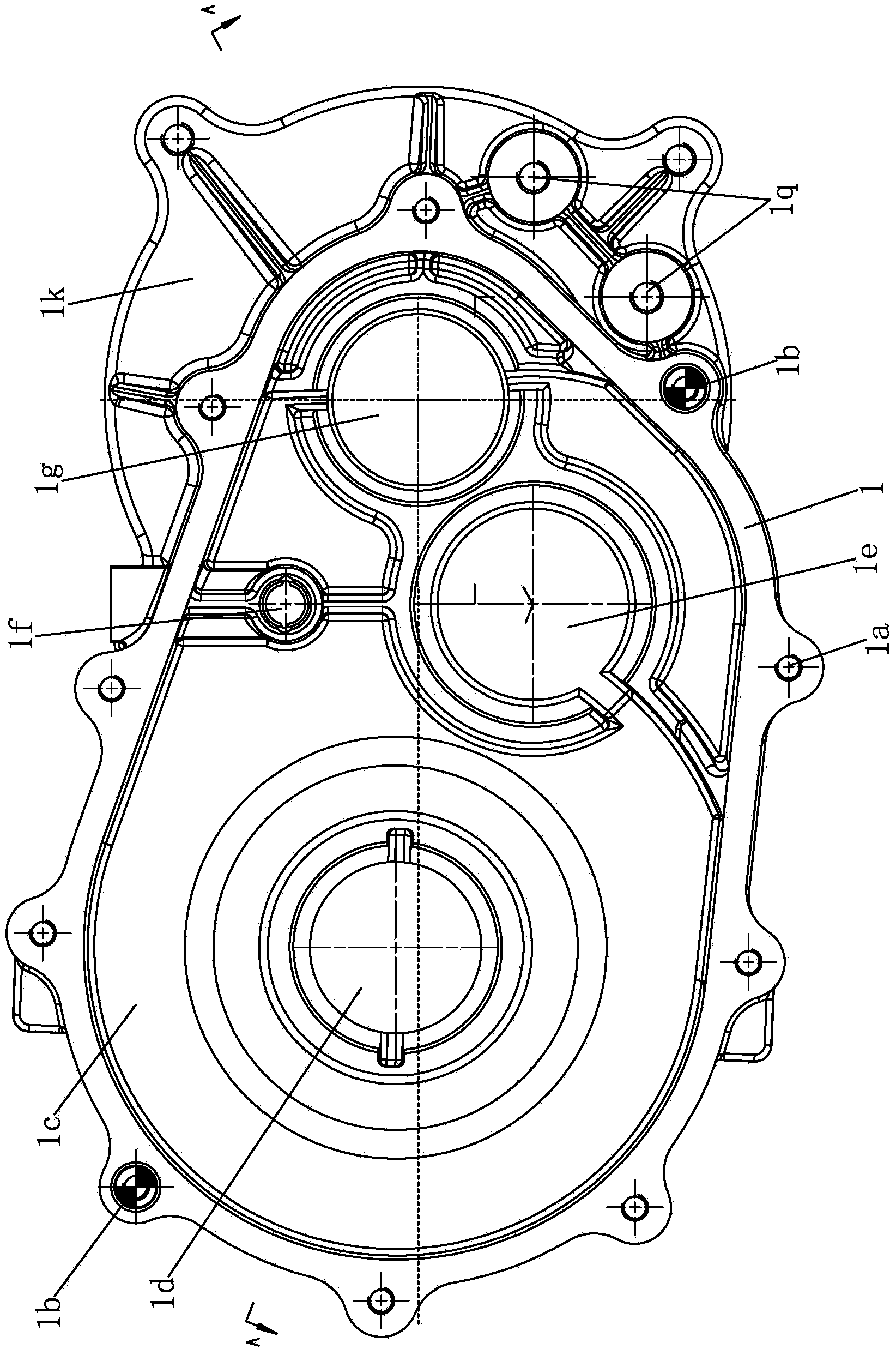

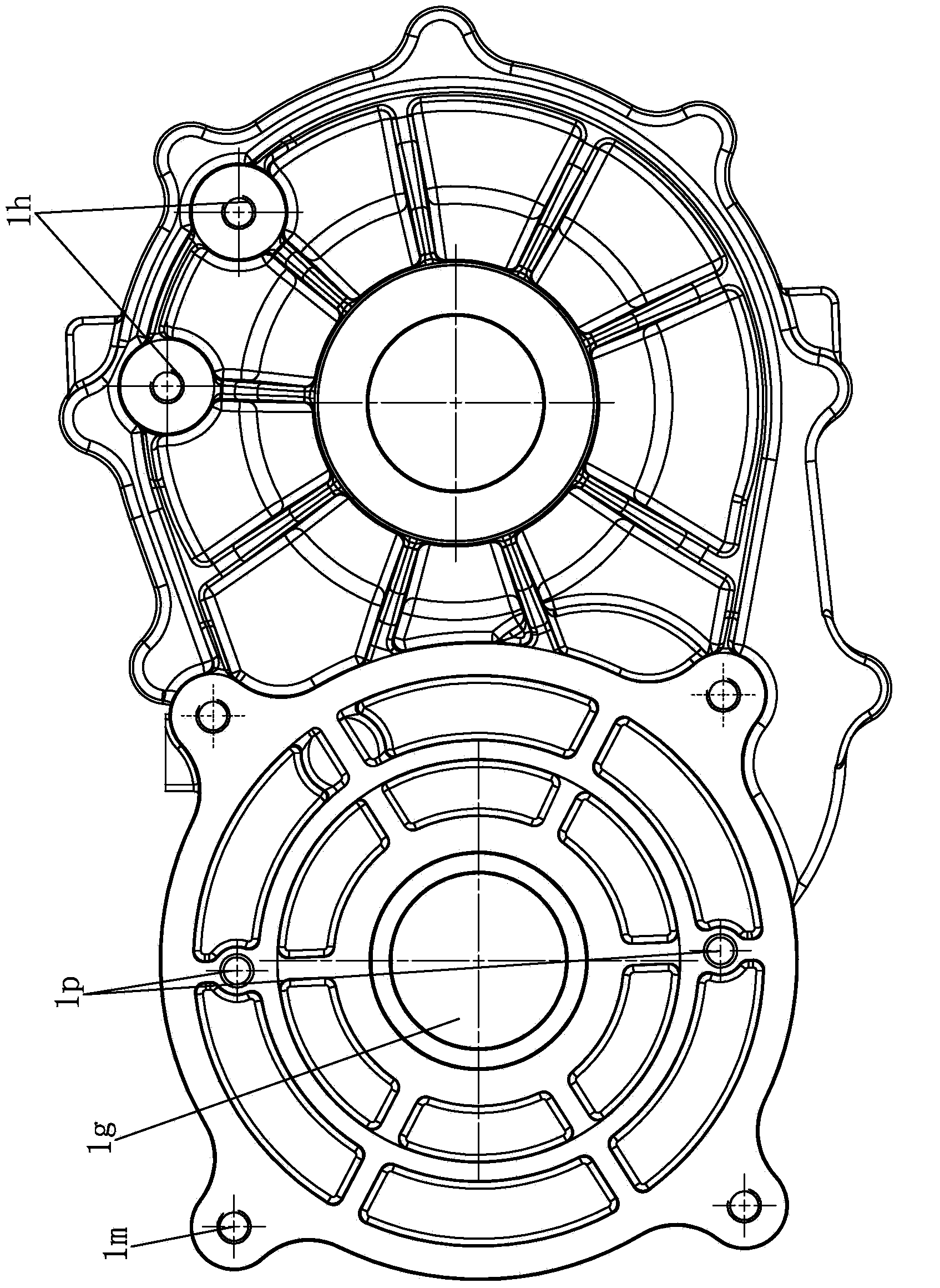

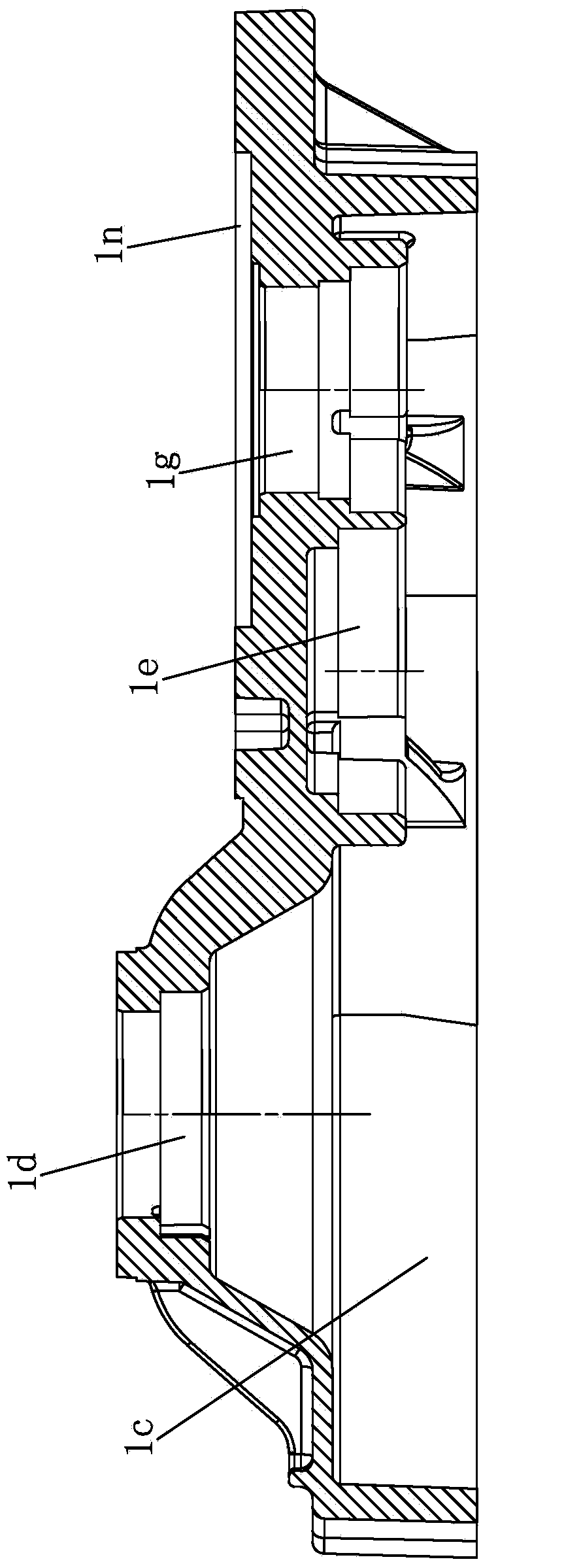

[0014] Such as figure 1 , 2 Shown in and 3, a kind of right case body of second gear electric vehicle transmission assembly, the body 1 of this right case body is a steel casting. The front side of the body 1 is a circle of box closing surface, on which there are 8 bolt mounting holes 1a and 2 positioning pin holes 1b along the circumference, wherein the bolt mounting holes 1a are threaded blind holes. During assembly, the closing surface of the right box and the closing surface of the left box are attached, and are fixedly connected by 8 bolts, and the roots of the bolts are fixed in the bolt installation holes 1a. The first positioning pin hole 1b is set on the upper left part of the body 1, and the second positioning pin hole 1b is set on the lower right part of the body 1. These two positioning pin holes are blind holes and are used for positioning the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com