Engine braking device

An engine braking and engine technology, applied in engine control, engine components, machines/engines, etc., can solve the problems of complex compression braking structure, high cost, large braking power, etc., and achieve simple structure, low cost, and rigidity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

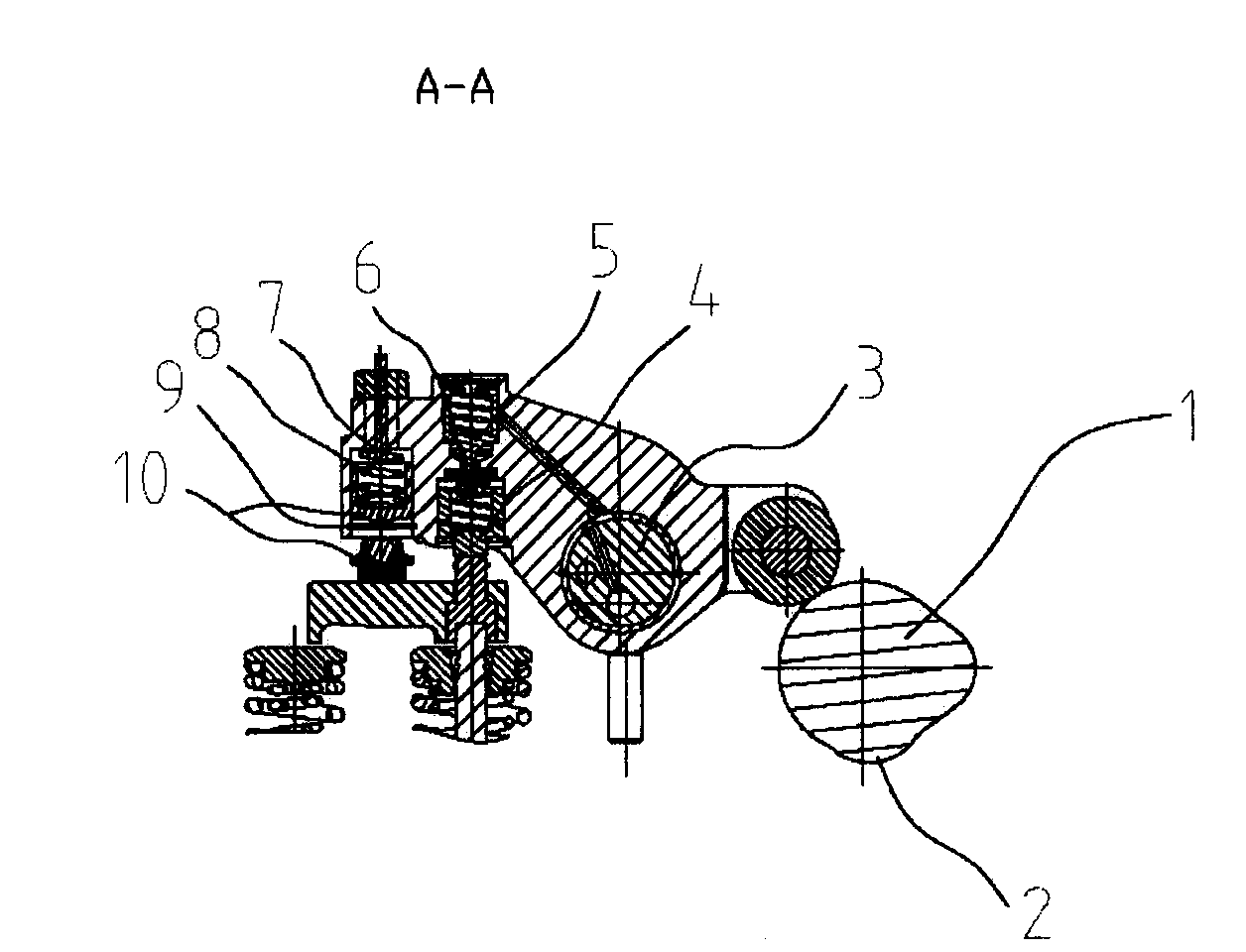

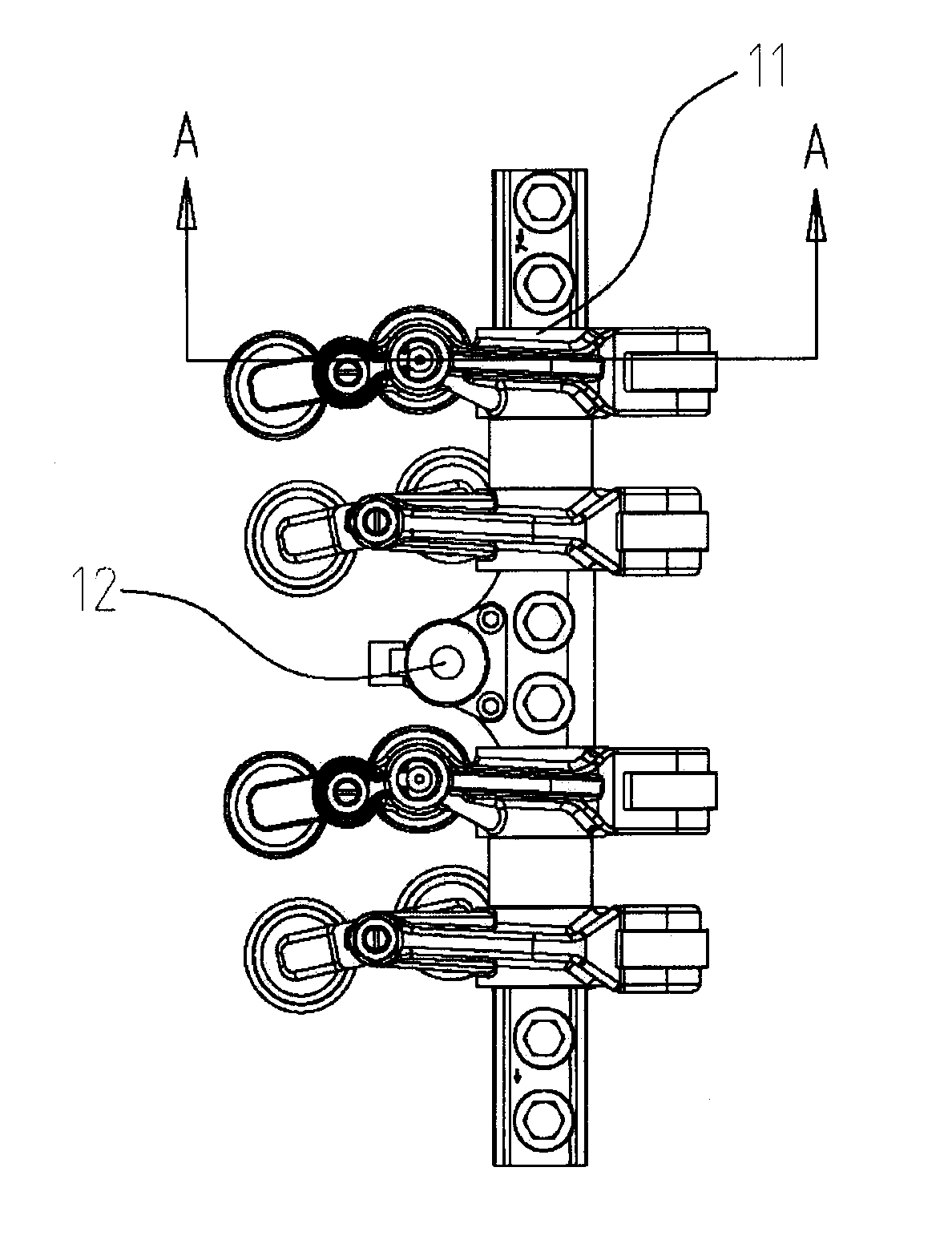

[0013] There is a brake cam 2 specially used for engine braking on the exhaust cam 1 of the camshaft. When the engine brake is required, the brake cam 2 can stop on the piston through the oil circuit control of the solenoid valve 12. Open an exhaust valve near the point to release the high-pressure gas in the cylinder to realize engine braking; when the engine does not need engine braking, the lift generated by the brake cam 2 can be compensated by the clearance in the exhaust rocker arm 11 The device compensates out without opening the exhaust valve.

[0014] There is a cavity under the hole of the adjustment bolt at the front end of the exhaust rocker arm 11 - the exhaust valve rocker arm 7, and the exhaust valve leg assembly 10 is fixed in the cavity by a snap ring, and the exhaust valve leg assembly 10 can be The cavity slides up and down, and a return spring is installed in it, so that the exhaust valve elephant foot assembly 10 is in contact with the snap ring 9 at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com