High-speed electric main shaft device where ultra-precise angular contact ball and cylindrical roller bearings are used

A technology for cylindrical roller bearings and high-speed motorized spindles, which is used in maintenance and safety accessories, large fixed members, metal processing machinery parts, etc., which can solve the difficulty of test bearing disassembly and assembly, the inability to accurately lubricate a single specific bearing, and the inability to reflect the running performance. and other problems, to achieve the effect of accurate quantitative lubrication, convenient, good rigidity and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

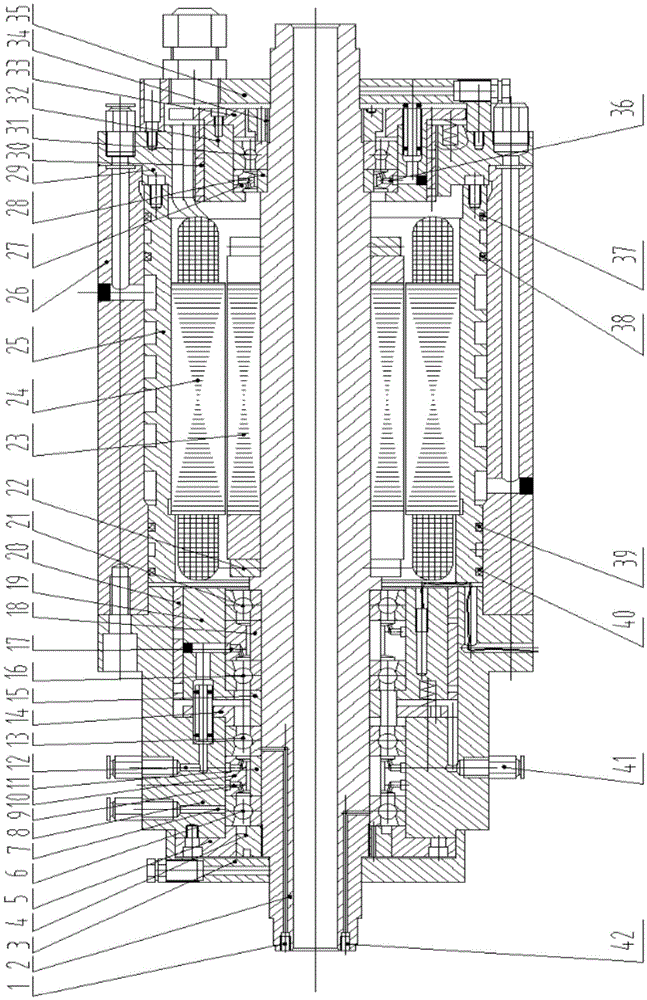

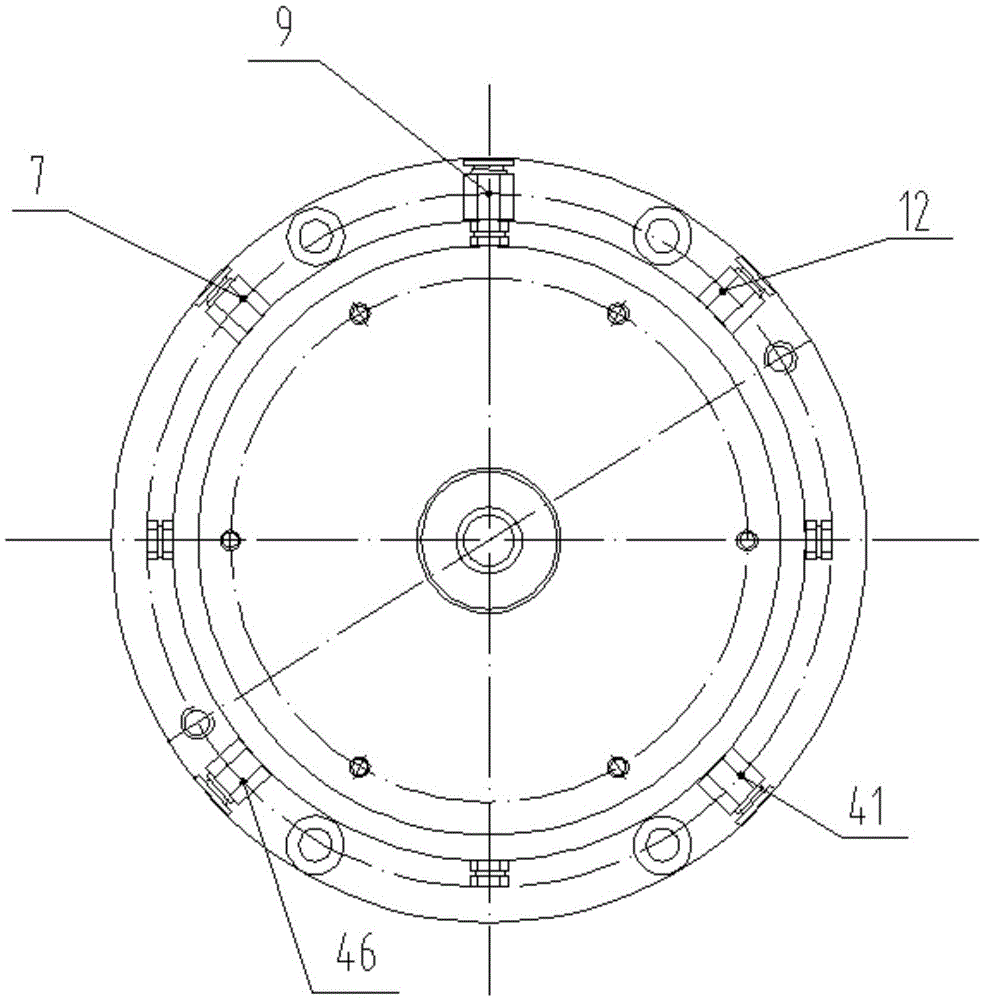

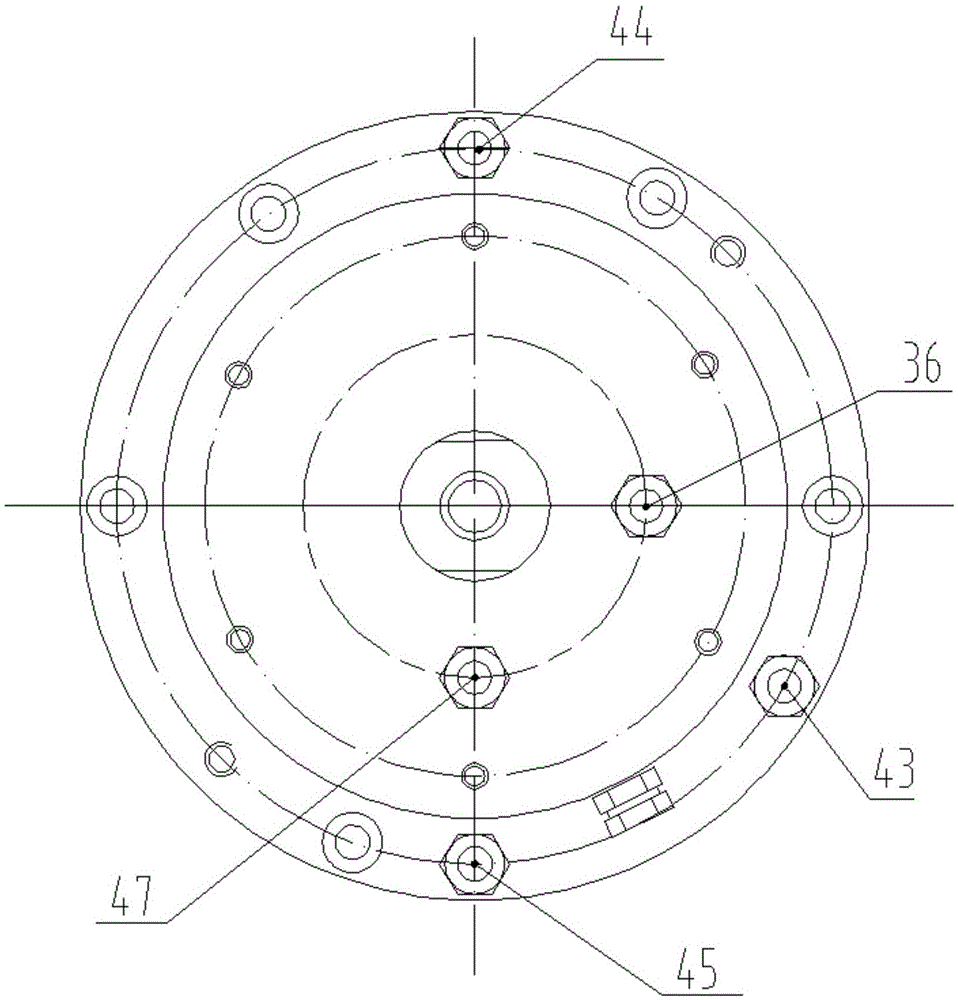

[0021] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] refer to figure 1 , figure 2 and image 3 , a high-speed electric spindle experimental device supported by angular contact balls and cylindrical roller bearings, including a housing 26, the housing 26 is used as the motor base, the cooling water jacket 25 is interference-fitted in the housing 26, and the motor stator 24 is interference-fitted Cooperate installed in the cooling water jacket 25, the motor rotor 23 and balance ring 22 are installed on the rotating shaft 2 with interference fit, the motor rotor 23 corresponds to the motor stator 24; the rear end of the rotating shaft 2 is provided with a single row cylindrical roller bearing 31, single row The front side of the cylindrical roller bearing 31 is positioned through the contact between the rear inner spacer 28 and the steps of the rotor 2, and the rear outer spacer 27 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com