Aluminum alloy translation sealing sliding door and window hardware structure

A sliding door and window, aluminum alloy technology, applied in the direction of window/door frame, building structure, wing frame, etc., can solve the problems of poor wind pressure resistance, wide door and window sash size, inability to adjust, etc., to achieve strong wind resistance , beautiful appearance, convenient processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to fully illustrate the technical means and creative features for realizing the present invention, the present invention will be further described below with reference to specific embodiments.

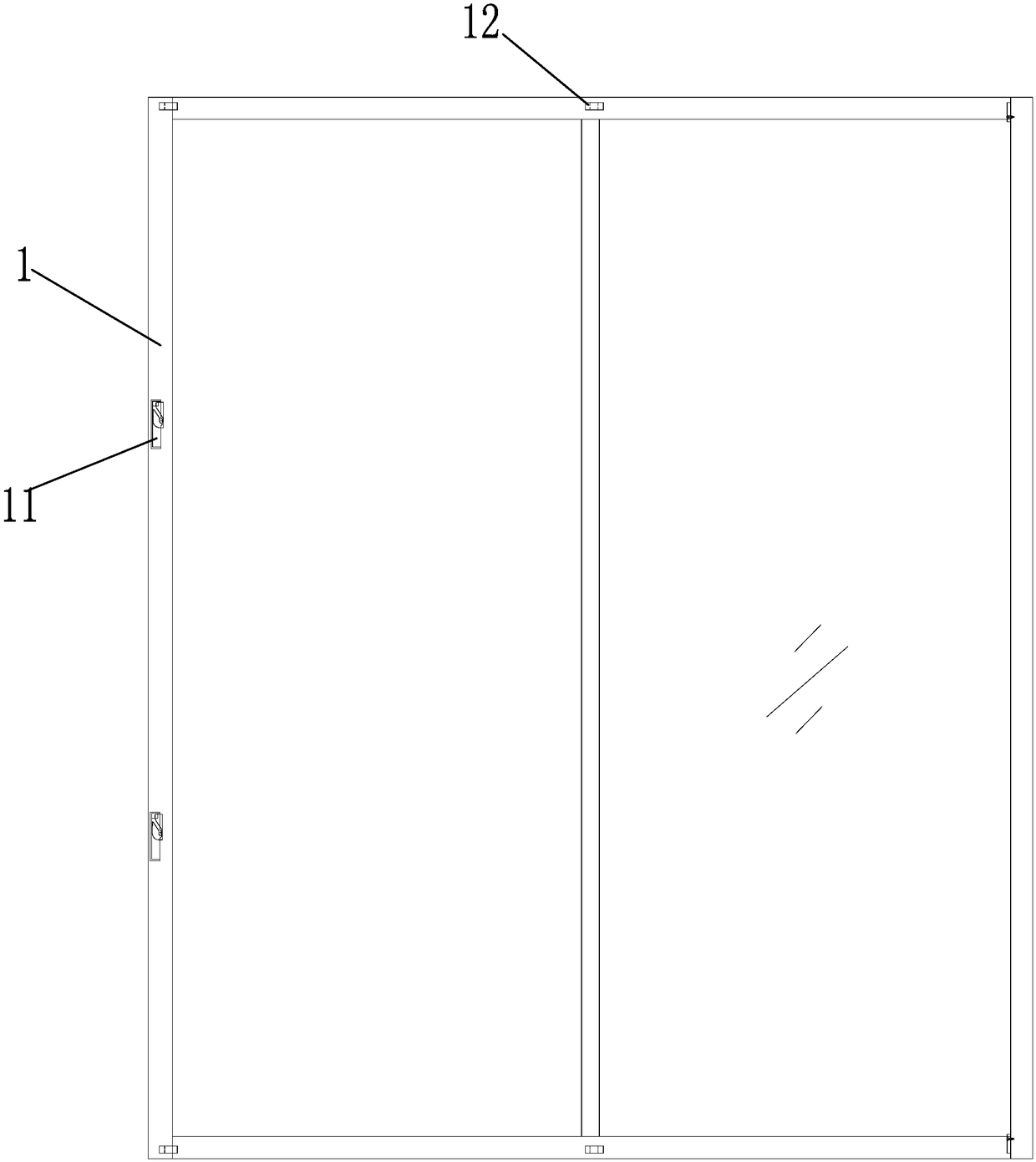

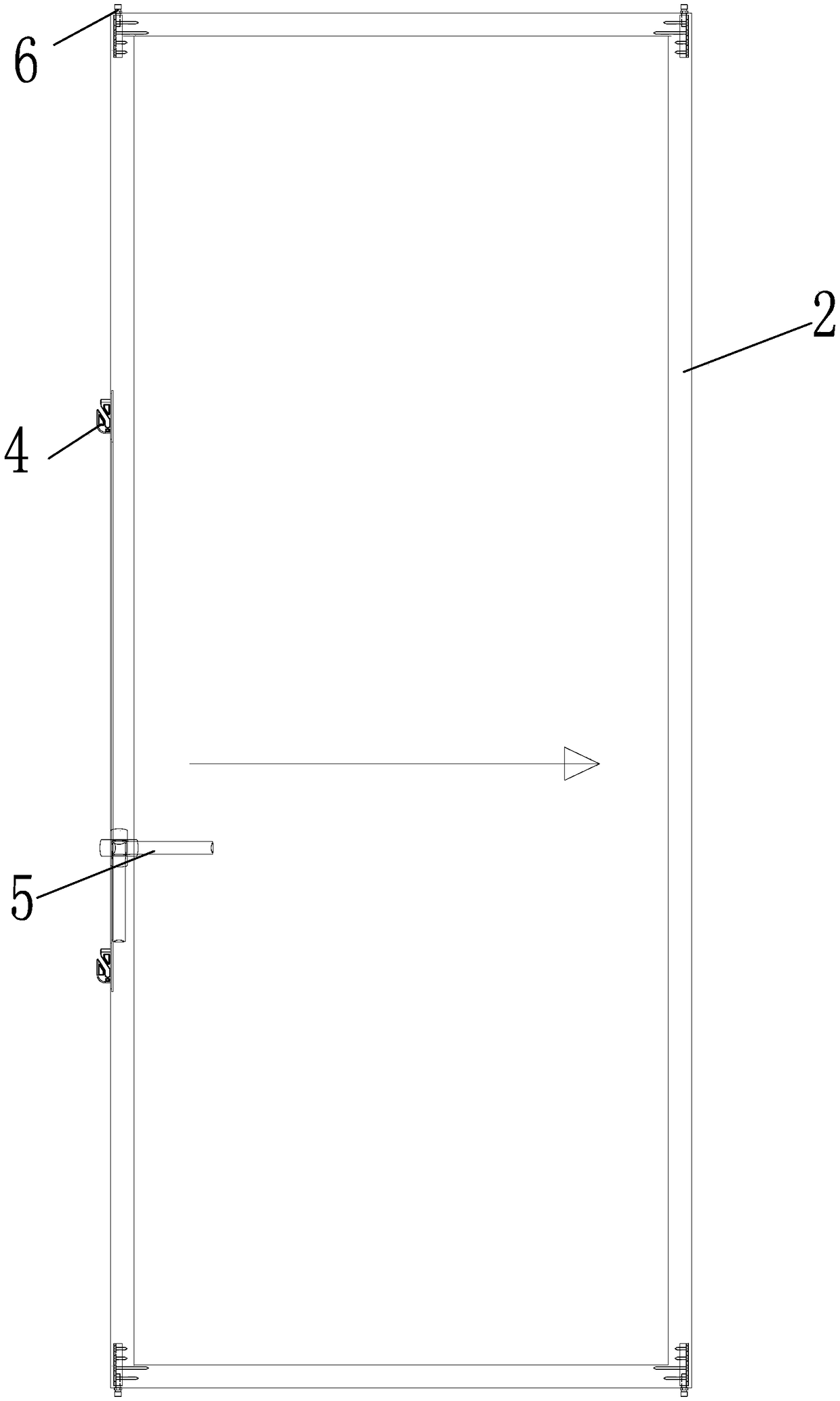

[0041] like Figure 1-Figure 2 As shown, the present invention provides an aluminum alloy translation sealing sliding door and window hardware structure, which includes a frame material 1 and a fan material 2 in the frame material 1. closed position and open position.

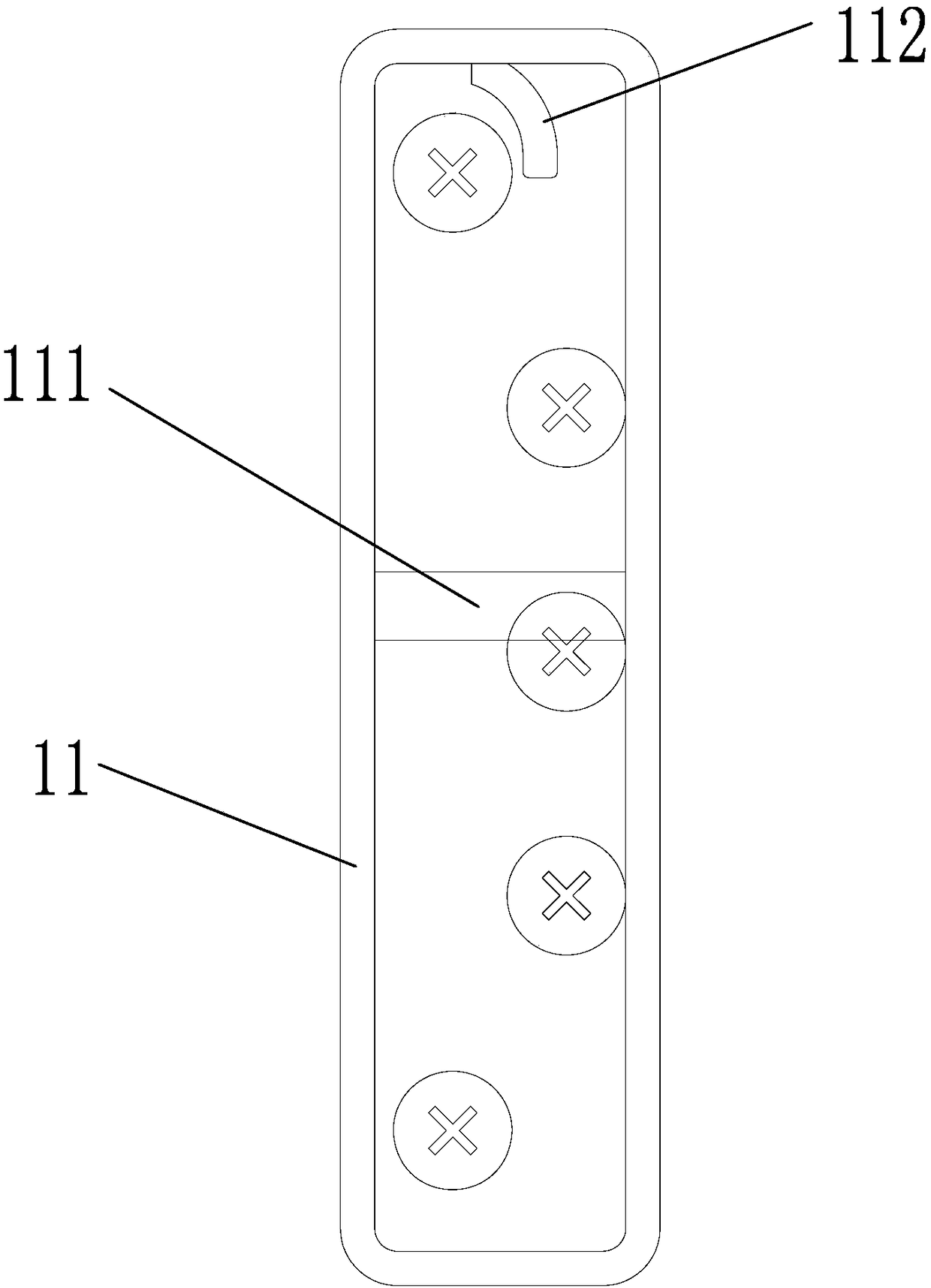

[0042] like Figure 3-Figure 14 As shown, one side of the frame material 1 adjacent to the closed position is provided with a hook lock seat 11 , and a horizontal pin shaft 111 is arranged in the hook lock seat 11 . Guide pin seats 12 are provided inside the top and bottom of the frame 1 adjacent to the closed position. The guide bolt seat 12 has a first guide groove 121 which is arc-shaped in the horizontal direction.

[0043] The side of the fan 2 facing the hook lock seat 11 is provided with a fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com