Stamped support for solar heat-collecting power generation system

A solar heat collection and power generation system technology, applied in the field of stamping supports, can solve the problems of loose bolt connection and insufficient bearing strength, and achieve the effects of easy installation, high bearing strength and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

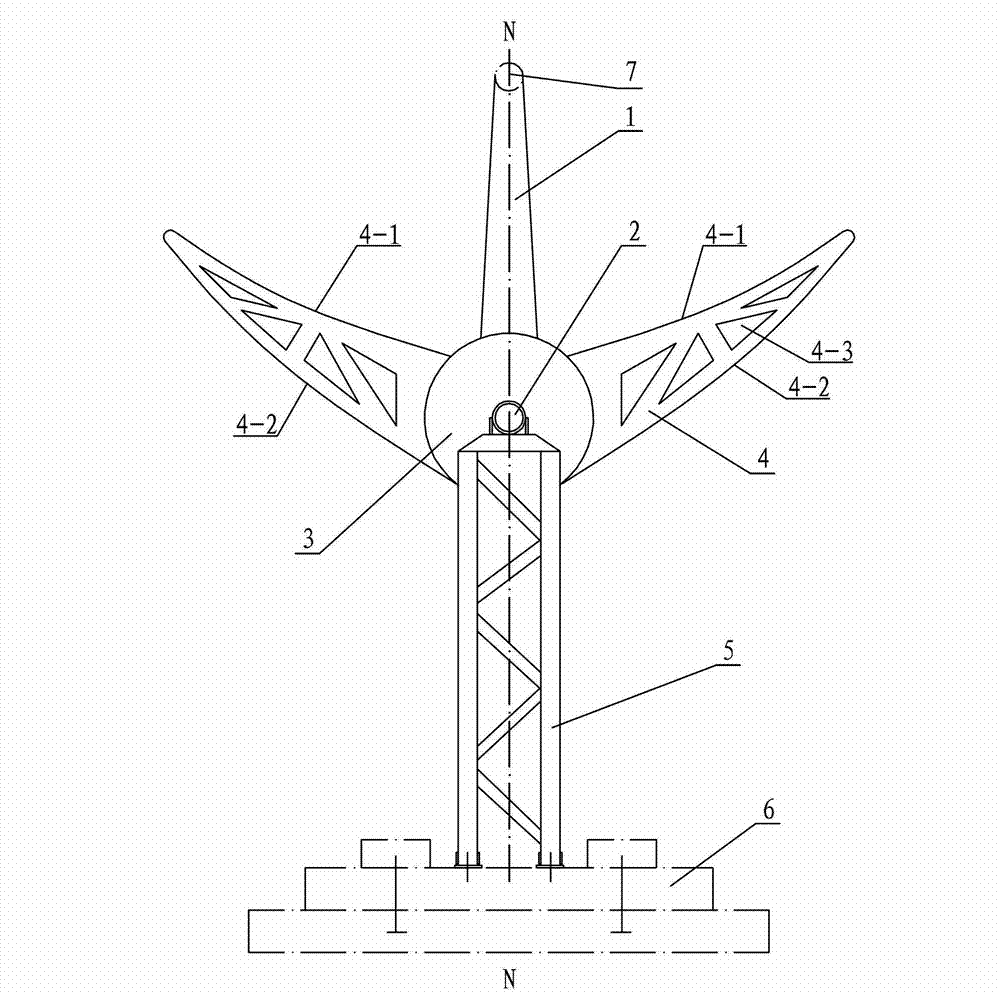

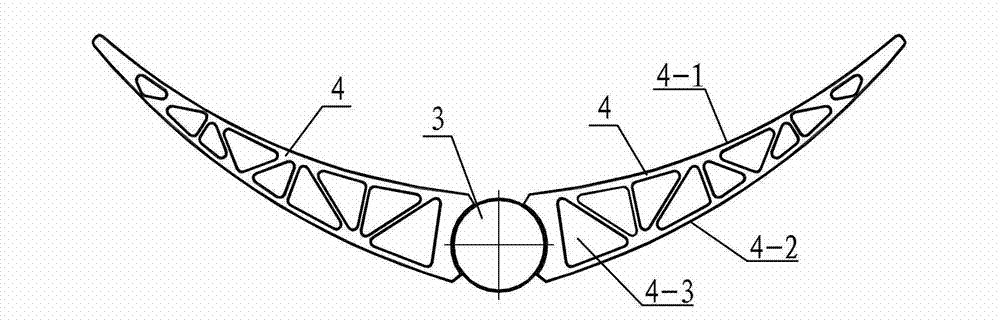

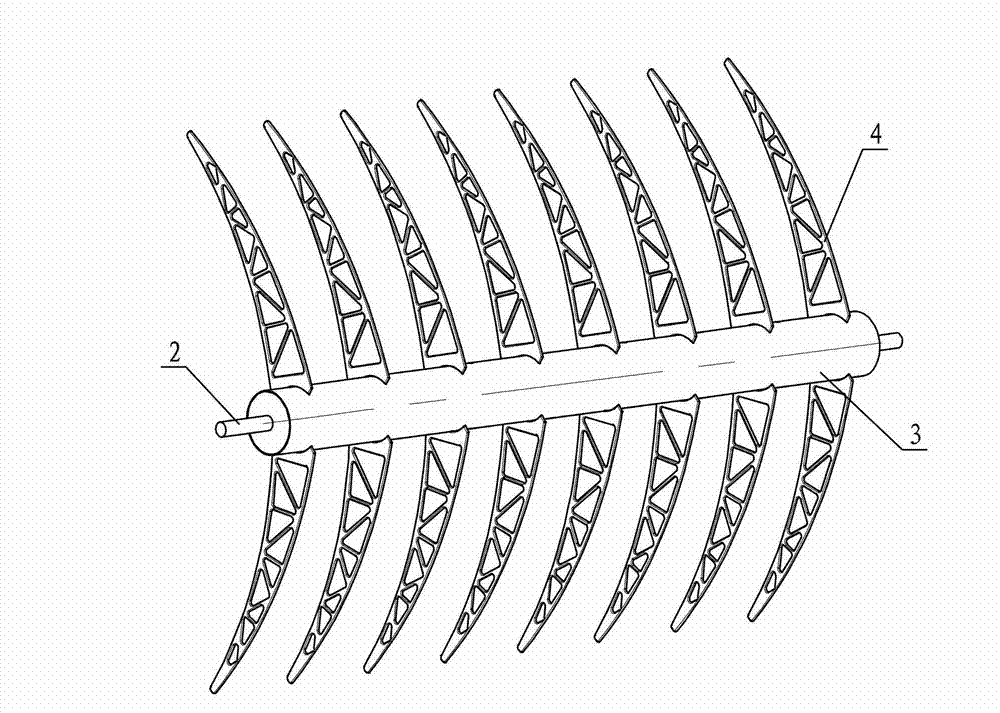

[0012] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, the stamping bracket of this embodiment includes a rotating tube 3, two fixed shafts 2, two supporting tower bridges 5, at least sixteen stamping cantilevers 4 and several heat collecting tube supports 1, and the two fixed shafts 2 are symmetrical Welded at the axis of both ends of the rotating tube 3, the lower end of each fixed shaft 2 is equipped with a supporting tower bridge 5, the fixed shaft 2 is set in the rolling bearing 5-1 on the supporting tower bridge 5, and the upper end of each stamping cantilever 4 The end surface is an inner concave arc surface 4-1, the lower end surface of the stamping cantilever 4 is an outward convex arc surface 4-2, one end of the stamping cantilever 4 is narrower than the other end, and at least sixteen stamping cantilevers 4 are divided into eight groups, each Two sets of stamping cantilevers 4, eight sets of stamping cantilevers 4 are evenly ...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination Figure 4 Describe the present embodiment, the support tower bridge 5 of the present embodiment is made of rolling bearing 5-1, transverse connection plate 5-2, support ring seat 5-3, two support rods 5-4, two support rod bases 5-5 and Several reinforcing ribs 5-6 are formed, and the transverse connecting plate 5-2 is arranged on the upper ends of two supporting rods 5-4 arranged in parallel, and the transverse connecting plate 5-2 is fixedly connected with the supporting rod 5-4, and the supporting ring seat 5- 3 is fixed on the upper end surface of the transverse connecting plate 5-2, the rolling bearing 5-1 is fixed on the support ring seat 5-3, and a support rod base 5-5 is installed on the bottom of each support rod 5-4, several The reinforcing ribs 5-6 are alternately arranged along the two supporting rods 5-4, and the two ends of the reinforcing ribs 5-6 are respectively welded to the corresponding supporting rods 5-4...

specific Embodiment approach 3

[0014] Specific implementation mode three: combination Figure 5 Describe this embodiment, the heat collecting tube support 1 of this embodiment consists of an upper clamping arc plate 1-1, a lower supporting arc plate 1-2, a channel plate 1-3, a rigid support seat 1-4, and two rigid supports 1 -5 and two connecting pins 1-6, the upper clamping arc plate 1-1 and the lower support arc plate 1-2 are fastened and set, and the upper clamping arc plate 1-1 and the lower support arc plate 1-2 The inner hole is used to install the vacuum heat collecting tube 7, and the upper clamping arc plate 1-1 and the lower supporting arc plate 1-2 are set in the groove of the grooved plate 1-3, and the lower supporting arc plate 1- The two ends of 2 are respectively hinged to the side wall of the grooved plate 1-3 through two connecting pins 1-6, two rigid supports 1-5 and above clamp the centerline N-N of the arc plate 1-1 symmetrically arranged, and the rigid support 1 The upper end of -5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com