Water-based ultraviolet-curing anti-fingerprint coating and preparation method thereof

An ultraviolet light and anti-fingerprint technology, which is applied in antifouling/underwater coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve problems such as impact, achieve low odor, short curing time, and excellent anti-fingerprint effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0036] Carry out coating preparation according to the coating formula of table 1, concrete preparation process is as follows:

[0037] (1) Mix the antifouling resin, UV-curable monomer, photoinitiator and film-forming aid, and stir at 500-1000r / min for 5-10min until uniformly mixed to obtain a primary mixture;

[0038] (2) Under stirring conditions, add water-based UV-curable oligomer to the primary mixture, stir at 500-1000r / min for 10-15min until evenly mixed, then add deionized water, wetting agent and leveling agent, Disperse at 1000-3000r / min for 0.5-1h, filter and discharge to obtain the water-based UV-curable anti-fingerprint coating.

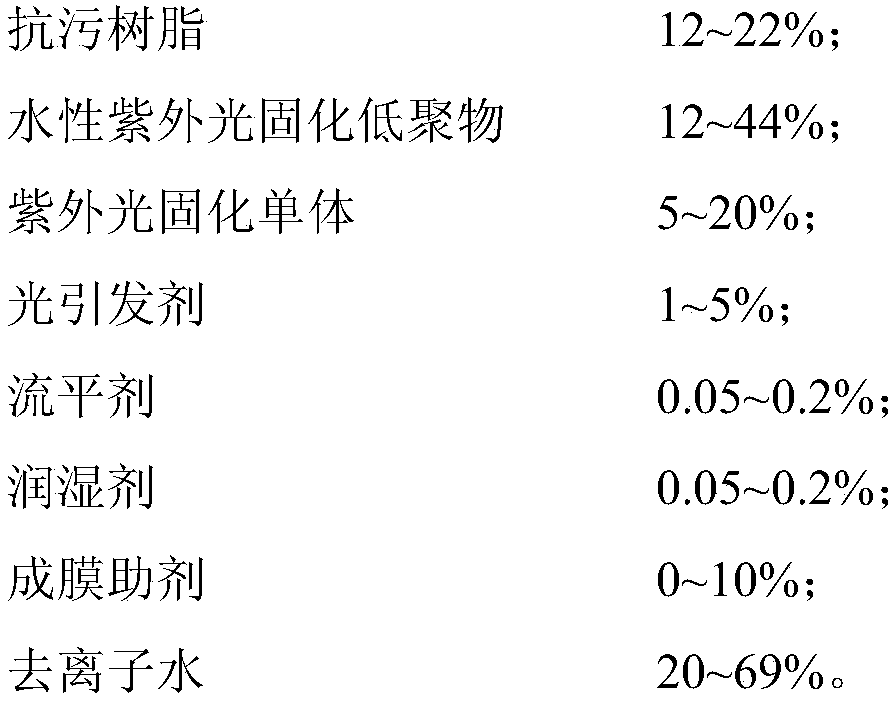

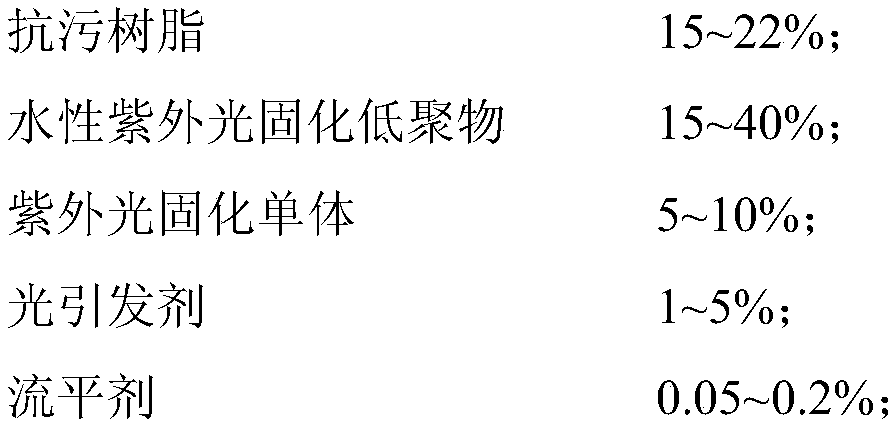

[0039] Table 1

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com