Metal surface anti-fingerprint treatment method and metal product prepared by the metal surface anti-fingerprint treatment method

A processing method and technology for metal surfaces, applied in metal material coating process, ion implantation plating, coating and other directions, can solve problems such as difficult preparation, complex composition and structure, environmental pollution, etc. fingerprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

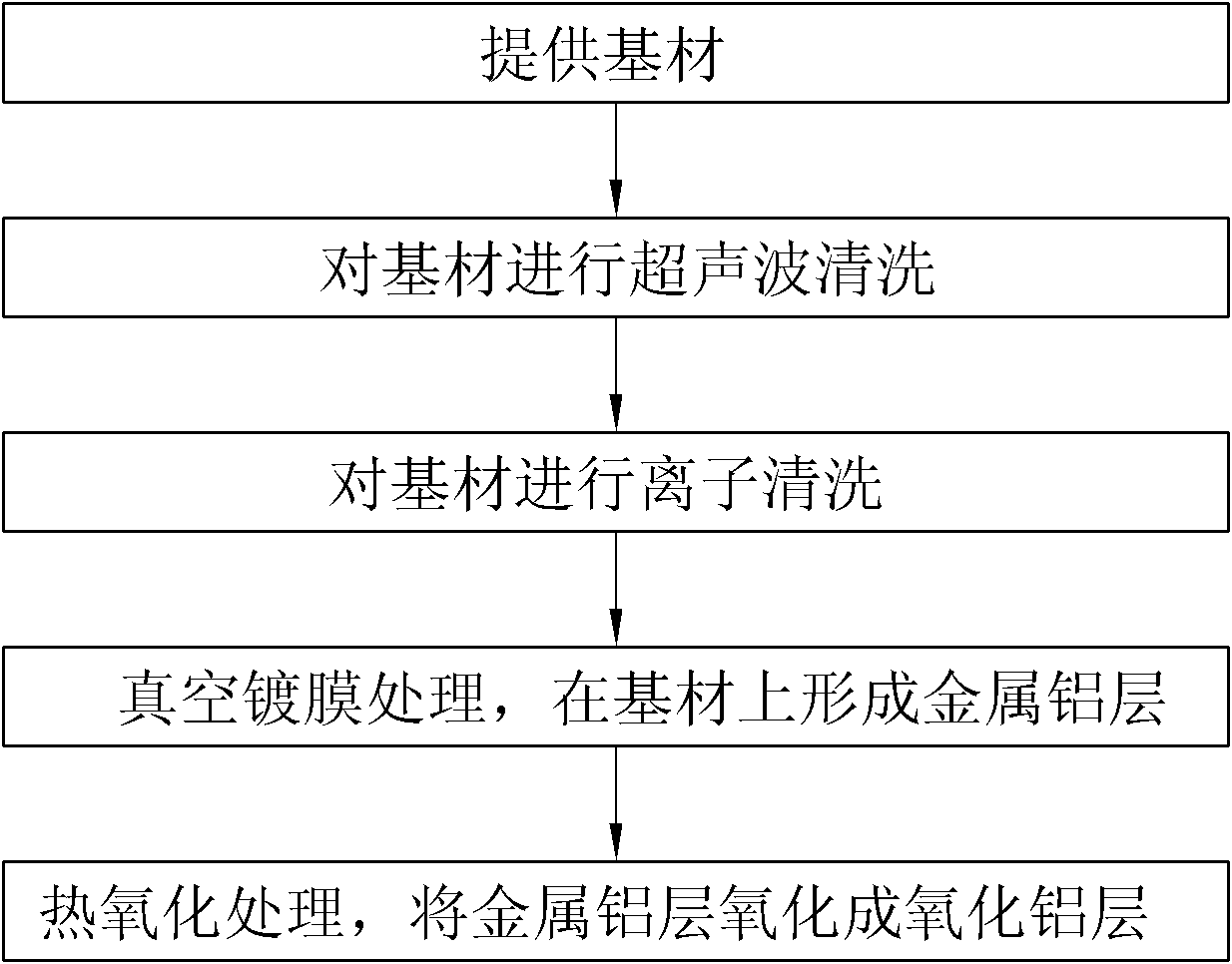

Method used

Image

Examples

Embodiment 1

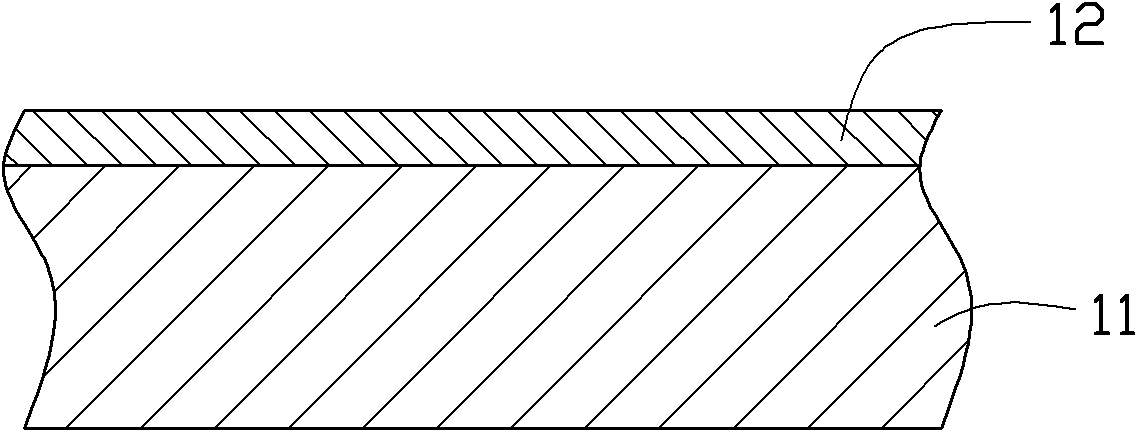

[0032] Select the stainless steel substrate, wash it in an ultrasonic cleaner filled with ethanol solution for 2 to 3 minutes, and then dry it. Put the substrate into the vacuum chamber of the DC magnetron sputtering equipment, and evacuate the vacuum chamber to 3.0×10 -3 After Pa, the flow rate was 20sccm nitrogen gas, the ion source power was turned on, the power was 1200w, and the ion source was turned off after 5 minutes of ion bombardment on the substrate.

[0033] Heat the vacuum chamber to 100°C, and feed argon gas with a flow rate of 290 sccm into the vacuum chamber, turn on the power of the pure aluminum target, the power of the target power is 3200w, adjust the bias voltage of the substrate to -120V, and deposit the metal aluminum layer . The deposition time is 10 min.

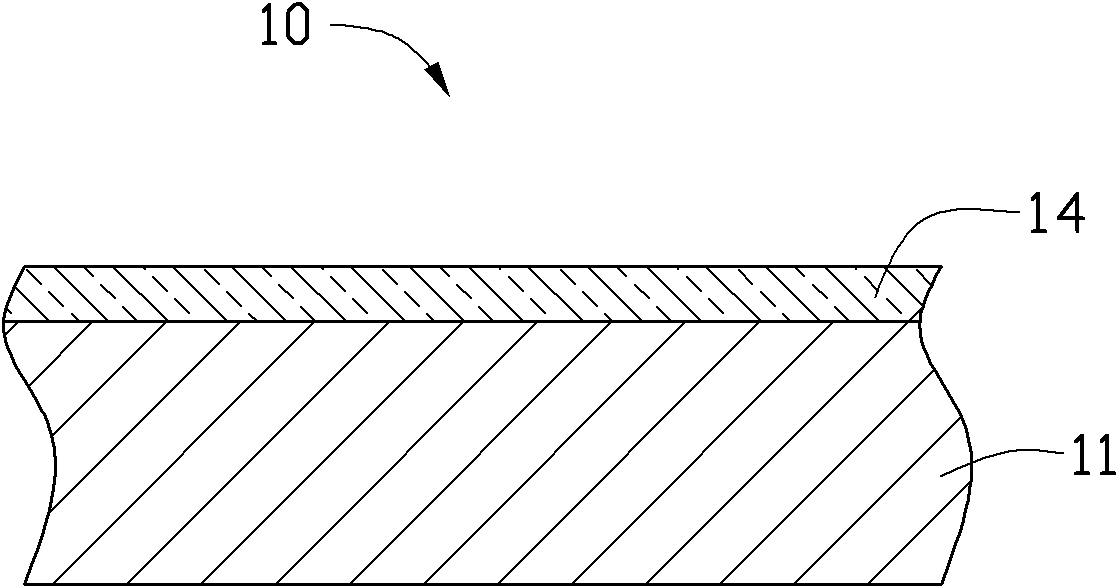

[0034] After the coating is finished, take out the substrate, put it into the oxidation furnace, and evacuate the oxidation furnace to 3.0×10 -3 Pa, set the treatment temperature at 350°C, and the...

Embodiment 2

[0037] Select the stainless steel substrate, wash it in an ultrasonic cleaner filled with ethanol solution for 2 to 3 minutes, and then dry it. Put the substrate into the vacuum chamber of the DC magnetron sputtering equipment, and evacuate the vacuum chamber to 3.0×10 -3 After Pa, the flow rate was 20sccm nitrogen gas, the ion source power was turned on, and the power was 900w, and the ion source was turned off after 8 minutes of ion bombardment on the substrate.

[0038] Heat the vacuum chamber to 120°C, and feed argon gas with a flow rate of 315 sccm into the vacuum chamber, turn on the power of the pure aluminum target, the power of the target power is 3900w, adjust the bias voltage of the substrate to -150V, and deposit the metal aluminum layer . The deposition time is 6 min.

[0039] After the coating is finished, take out the substrate, put it into the oxidation furnace, and evacuate the oxidation furnace to 3.0×10 -3 Pa, set the treatment temperature at 300°C, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com