Method for forming anti-fingerprint membrane on sanitary product

An anti-fingerprint film and bathroom product technology, applied in superimposed layer plating, ion implantation plating, coating and other directions, can solve problems such as poor wear resistance, easy wear, unfavorable environmental protection and human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

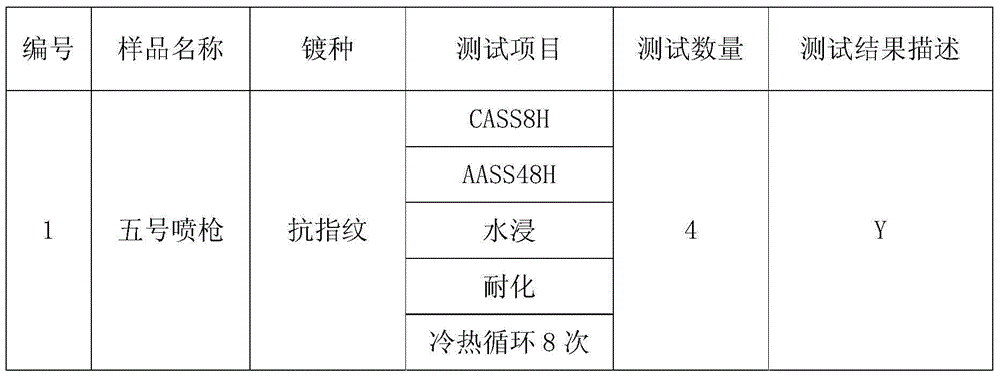

Embodiment 1

[0025] The preparation method of the anti-fingerprint film on the surface of ABS plastic bathroom products, the preparation process comprises the following steps:

[0026] Step (1): Degrease the surface of the ABS plastic bathroom product with wire drawing lines after nickel plating, and the degreasing is carried out by vacuum hydrocarbon cleaning technology;

[0027] Step (2): Transfer the ABS plastic sanitary products processed in step (1) to a vacuum coating rack, and hang them into the vacuum coating equipment for vacuum coating of a high corrosion-resistant alloy film layer. The vacuum deposition process is: first Plasma glow treatment, the process is: put the ABS plastic sanitary products into the PVD vacuum equipment for vacuuming, when the vacuum degree reaches 10 -2 Pa, the process conditions are ion source current 0.8A, duty cycle 20%, argon flow rate 200SCCM, time 10min, in order to achieve the purpose of cleaning and activating the surface of the substrate.

[002...

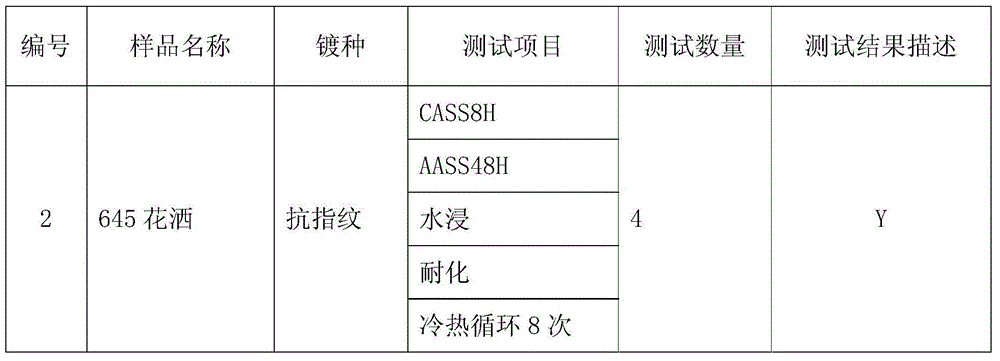

Embodiment 2

[0037] The preparation method of the anti-fingerprint film on the surface of ABS+PC composite plastic bathroom products, the preparation process comprises the following steps:

[0038]Step (1): Degrease the surface of the ABS+PC composite plastic sanitary product with brushed texture after electroplating nickel, and the degreasing is carried out by vacuum hydrocarbon cleaning technology;

[0039] Step (2): Transfer the ABS+PC composite plastic sanitary products processed in step (1) to the vacuum coating rack, and hang them into the vacuum coating equipment for vacuum coating of a high corrosion-resistant alloy film layer. The vacuum deposition process is as follows: : Plasma glow treatment first, the process is: put ABS+PC composite plastic sanitary products into PVD vacuum equipment, vacuumize, when the vacuum degree reaches 10 -2 Pa, the process conditions are ion source current 1.2A, duty cycle 40%, argon flow rate 400SCCM, time 5min, in order to achieve the purpose of cle...

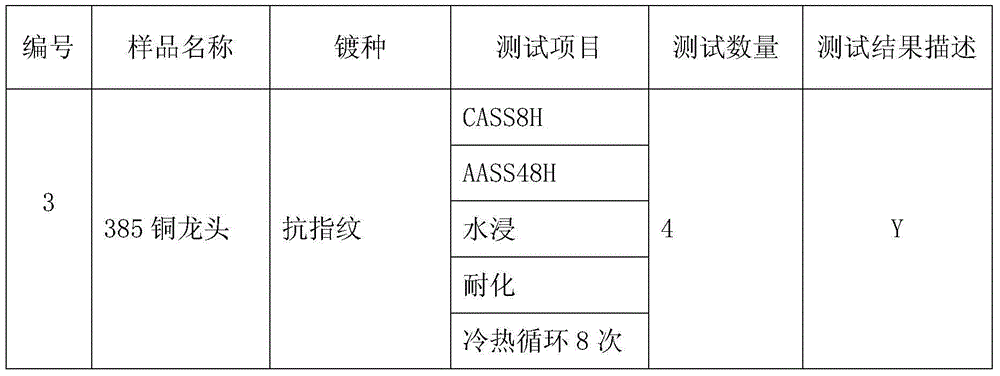

Embodiment 3

[0049] A method for preparing an anti-fingerprint film on the surface of a copper faucet bathroom product, the preparation process comprising the following steps:

[0050] Step (1): Degrease the surface of the copper faucet bathroom product with wire drawing lines after nickel plating, and the degreasing is carried out by vacuum hydrocarbon cleaning technology;

[0051] Step (2): Transfer the copper faucet bathroom products treated in step (1) to a vacuum coating rack, and hang them into the vacuum coating equipment to vacuum-plate a high-corrosion-resistant alloy film on the surface. The vacuum deposition process is: first Plasma glow treatment, the process is: put the copper faucet bathroom products into the PVD vacuum equipment, vacuumize, when the vacuum degree reaches 10 -2 Pa, the process conditions are ion source current 10A, duty cycle 30%, argon flow rate 300SCCM, time 7min, in order to achieve the purpose of cleaning and activating the surface of the substrate.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com