Anti-dazzle, anti-reflection and anti-fingerprint film

An anti-glare and anti-reflection technology, which is applied in the direction of film/sheet adhesives, adhesives, etc., can solve the problems of products that cannot meet the use requirements, poor explosion-proof performance of glass, and low production yield, and achieve good anti-reflection effects. High hardness, good wear resistance, good anti-fingerprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

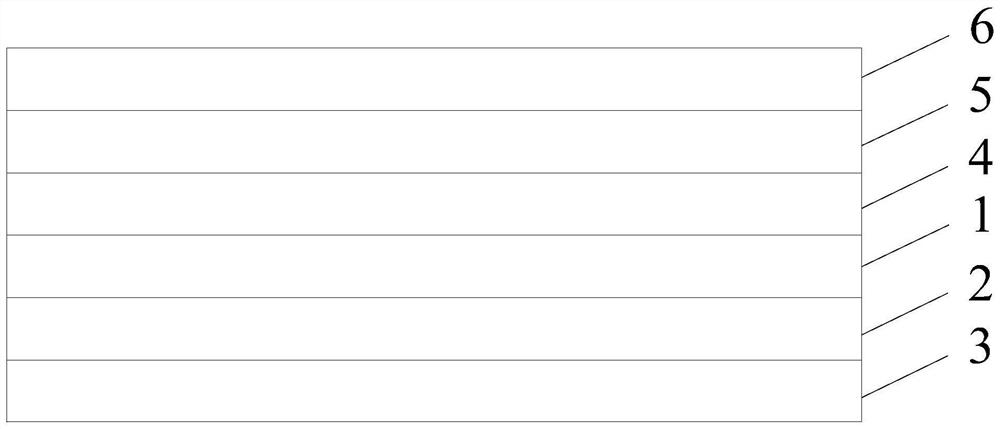

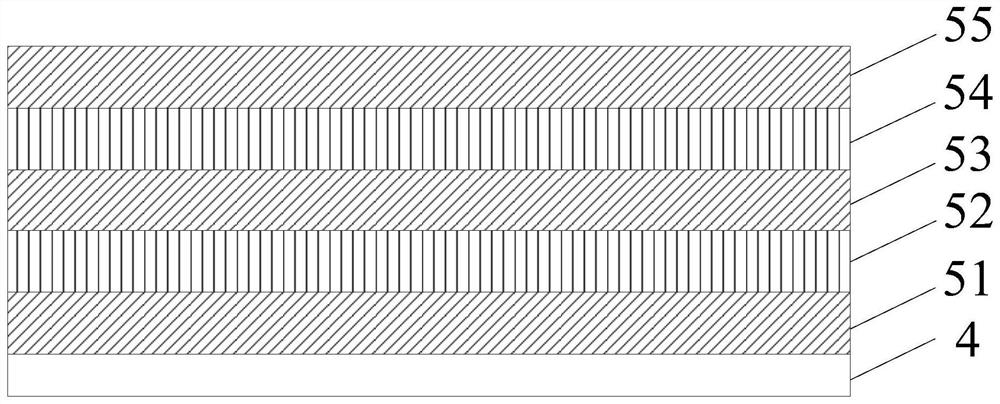

[0023] Embodiment: This application provides an anti-glare (English: Anti-glare, abbreviation: AG), anti-reflection (English: Anti-Reflection, abbreviation: AR) and anti-fingerprint (English: Anti-Finger, abbreviation: AF) ) of the film, combined with reference figure 1 and figure 2 , the film includes: a film base layer 1, an adhesive layer 2, a release film 3, an anti-glare layer 4, an anti-reflection layer 5, and an anti-fingerprint layer 6.

[0024] One side of the base film 1 is provided with an adhesive layer 2 and a release film 3 sequentially from the inside to the outside; the other side of the base film 1 is provided with an anti-glare layer 4 , an anti-reflection layer 5 and an anti-fingerprint layer 6 from the inside to the outside. The anti-glare layer 4 is prepared on the film base layer 1 by curing resin combined with UV transfer printing; the anti-reflection layer 5 is alternately laminated on the film layer by a first predetermined number of high-refractive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com