Surface treatment technology with ceramic and fingerprint simulating effects and application

A surface treatment and anti-fingerprint technology, which is applied to special surfaces, pre-treatment surfaces, and devices for coating liquids on surfaces, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

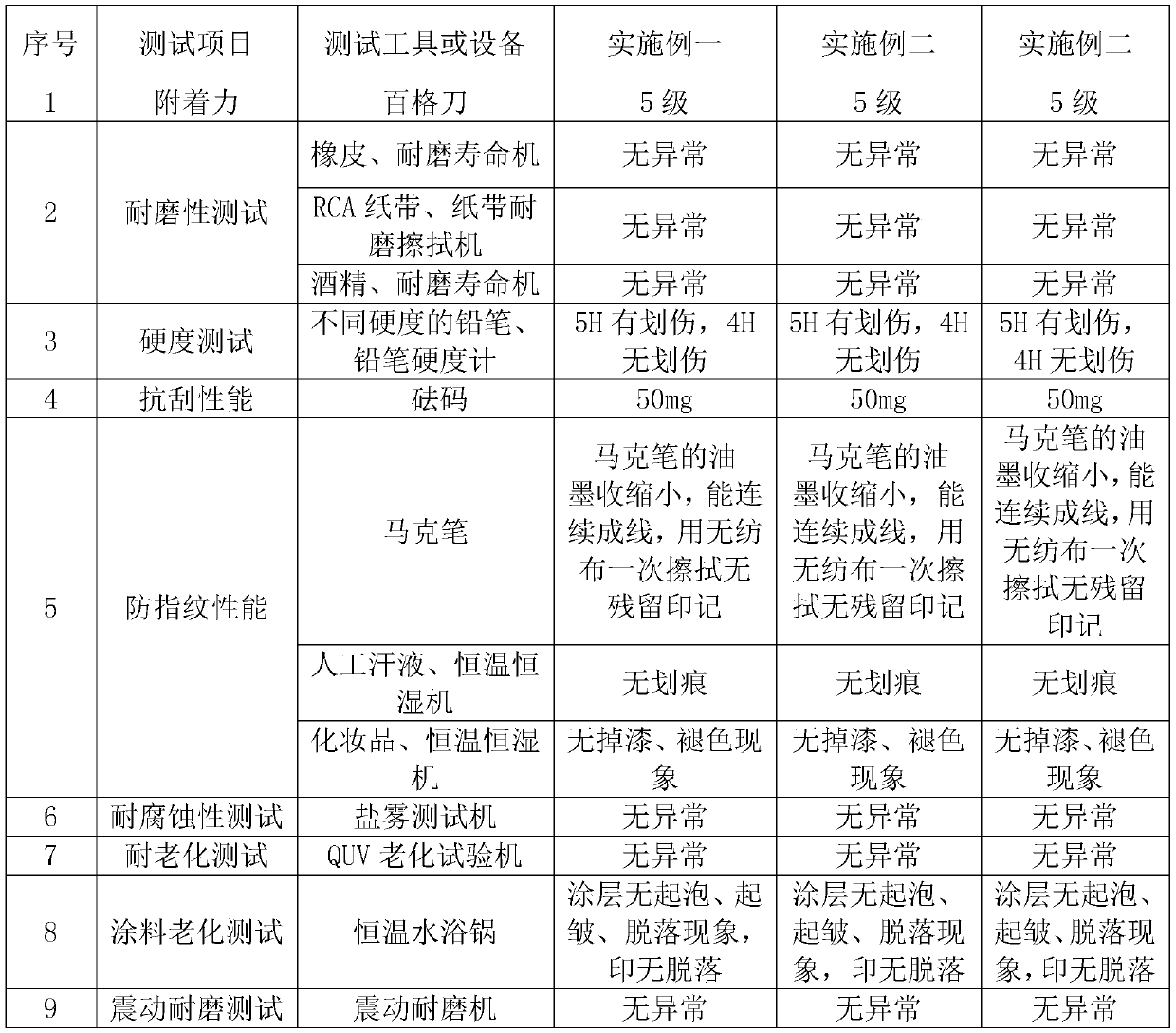

Examples

Embodiment 1

[0045] A surface treatment process with imitation ceramics and anti-fingerprint effects, comprising the following steps:

[0046] S1. Decontamination, cleaning and drying of the surface of the formed substrate;

[0047] S1', use a spray gun to spray 4um UV treatment agent on the surface of the sprayed part, and the UV energy is 400mj / cm 2 , baked at 50°C for 10 minutes.

[0048] S2, filter the UV primer with 400 mesh, adopt 3kg spraying air pressure, 10cm spraying distance, spray UV primer to the sprayed parts after cleaning under the environment of temperature and humidity 25°C / 75%RH, under the environment of 60°C Bake, cure for 10min, dry film thickness is 5μm, UV energy is 400mj / cm 2 ;(Please check and modify the data)

[0049] S2', print the ink brand logo on the surface of the sprayed part sprayed with UV primer by screen printing machine;

[0050] S3. Filter the topcoat with 400 mesh, use 3kg spraying air pressure, 10cm spraying distance, spray topcoat on the sprayed...

Embodiment 2

[0055] A surface treatment process with imitation ceramics and anti-fingerprint effects, comprising the following steps:

[0056] S1. Decontamination, cleaning and drying of the surface of the formed substrate;

[0057] S1', use a spray gun to spray 6um UV treatment agent on the surface of the sprayed part, and the UV energy is 300mj / cm 2 , baked at 55°C for 8 minutes.

[0058] S2, filter the UV primer with 400 mesh, adopt 3.5kg spraying air pressure, 15cm spraying distance, spray UV primer to the sprayed parts after cleaning under the environment of temperature and humidity 25 ℃ / 75% RH, in 65 ℃ environment Bake at bottom, cure for 7min, dry film thickness is 8μm, UV energy is 500mj / cm 2 ;

[0059] S2', print the ink brand logo on the surface of the sprayed part sprayed with UV primer by screen printing machine;

[0060] S3, filter the topcoat with 400 mesh, use 3.5kg spraying air pressure, 15cm spraying distance, spray topcoat on the sprayed part under the environment of ...

Embodiment 3

[0065] A surface treatment process with imitation ceramics and anti-fingerprint effects, comprising the following steps:

[0066] S1. Decontamination, cleaning and drying of the surface of the formed substrate;

[0067] S1', use a spray gun to spray 8um UV treatment agent on the surface of the sprayed part, and the UV energy is 400mj / cm 2 , bake at 60°C for 5min.

[0068] S2, filter the UV primer with 400 mesh, adopt 4kg spraying air pressure, 20cm spraying distance, spray UV primer to the sprayed parts after cleaning under the environment of temperature and humidity 25°C / 75%RH, under the environment of 70°C Bake and cure for 5 minutes, the dry film thickness is 11μm, and the UV energy is 600mj / cm 2 ;

[0069] S2', print the ink brand logo on the surface of the sprayed part sprayed with UV primer by screen printing machine;

[0070] S3. Filter the topcoat with 400 mesh, use 4kg spraying air pressure, 20cm spraying distance, spray the topcoat on the sprayed part under the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com