Silane modified fluorine-containing polymer as well as preparation method and fingerprint-proof paint thereof

A silane modification and polymer technology, applied in polyether coatings, coatings, etc., can solve the problems of anti-fingerprint effect and durability, and achieve excellent anti-fingerprint effect, easy to clean, and difficult to absorb water and oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

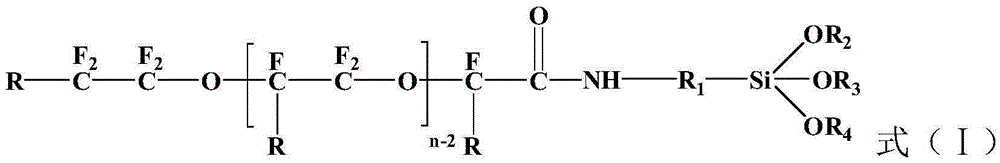

[0024] In a second aspect, the present invention provides a method for preparing a silane-modified fluoropolymer, the method comprising:

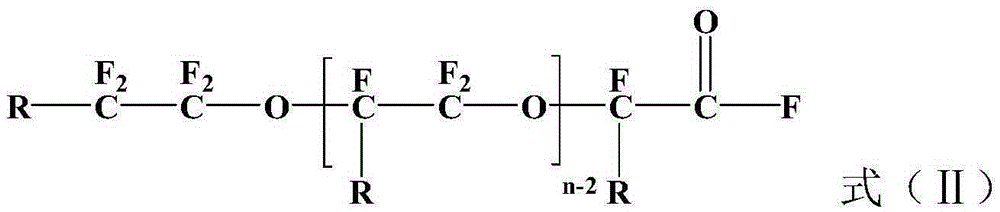

[0025] (1) In the presence of a fluorine-containing catalyst and an organic solvent, polymerize hexafluoropropylene oxide and / or tetrafluoroethylene oxide to obtain an intermediate represented by formula (II);

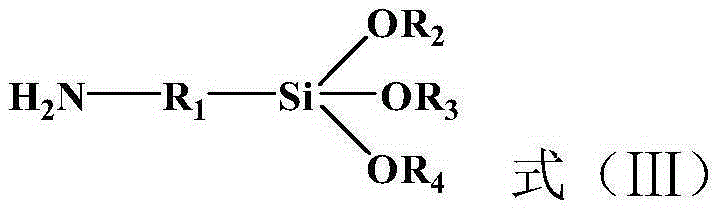

[0026] (2) Under an inert atmosphere, the intermediate shown in formula (II) is contacted with the aminosilane coupling agent shown in formula (III),

[0027]

[0028]

[0029] R in formula (II) is -CF 3 Or-F, the value of n makes the number-average molecular weight of fluoropolymer be 500-10000, R in the formula (Ⅲ) 1 for C 1 -C 16 Alkylene or phenylene, R 2 , R 3 , R 4 each independently as C 1 -C 16 Alkyl or -H.

[0030] According to the method of the present invention, preferably, the value of n in the formula (II) makes the number average molecular weight of the fluoropolymer be 4000-6500, R in the formula (III) ...

preparation example 1

[0057] This preparation example is used to illustrate the silane-modified fluoropolymer of the present invention and its preparation method.

[0058] (1) Take 1 g of dry cesium fluoride solid with an electronic balance and dissolve it in 6 g of ethylene glycol dimethyl ether to prepare a liquid catalyst and move it to a constant pressure dropping funnel;

[0059] (2) Add the above-mentioned liquid catalyst into a completely dry 250mL three-necked flask, then stir the liquid catalyst, and set the stirring speed to 600r / min. Inject dry hexafluoropropylene oxide gas, stop feeding after introducing 200g of hexafluoropropylene oxide gas, then seal the three-neck flask and adjust the rotation speed to 300r / min, and continue the reaction for 15h. After the reaction was completed, the temperature was slowly raised to 5°C, and the reaction product was evacuated for 2 hours at the same time to obtain a white viscous liquid product;

[0060] (3) Under nitrogen protection and room temper...

Embodiment 1

[0064] This example is used to illustrate the anti-fingerprint coating of the present invention and its preparation method.

[0065] At room temperature, add 0.05 g of aluminum acetylacetonate and 0.3 g of the product A1 prepared in Preparation Example 1 to 100 g of perfluorinated solvent SV-70, and then stir at a stirring speed of 200 r / min for 30 min to obtain an anti-fingerprint Paint B1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com