Curved screen protection film and preparation method thereof

A technology of curved screen and protective film, applied in the direction of pressure-sensitive film/sheet, film/sheet release liner, film/sheet release coating, etc., can solve the problem that the bending property of the protective film cannot meet the requirements, warping and so on , to achieve the effect of improving fixation, improving flexibility, and improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

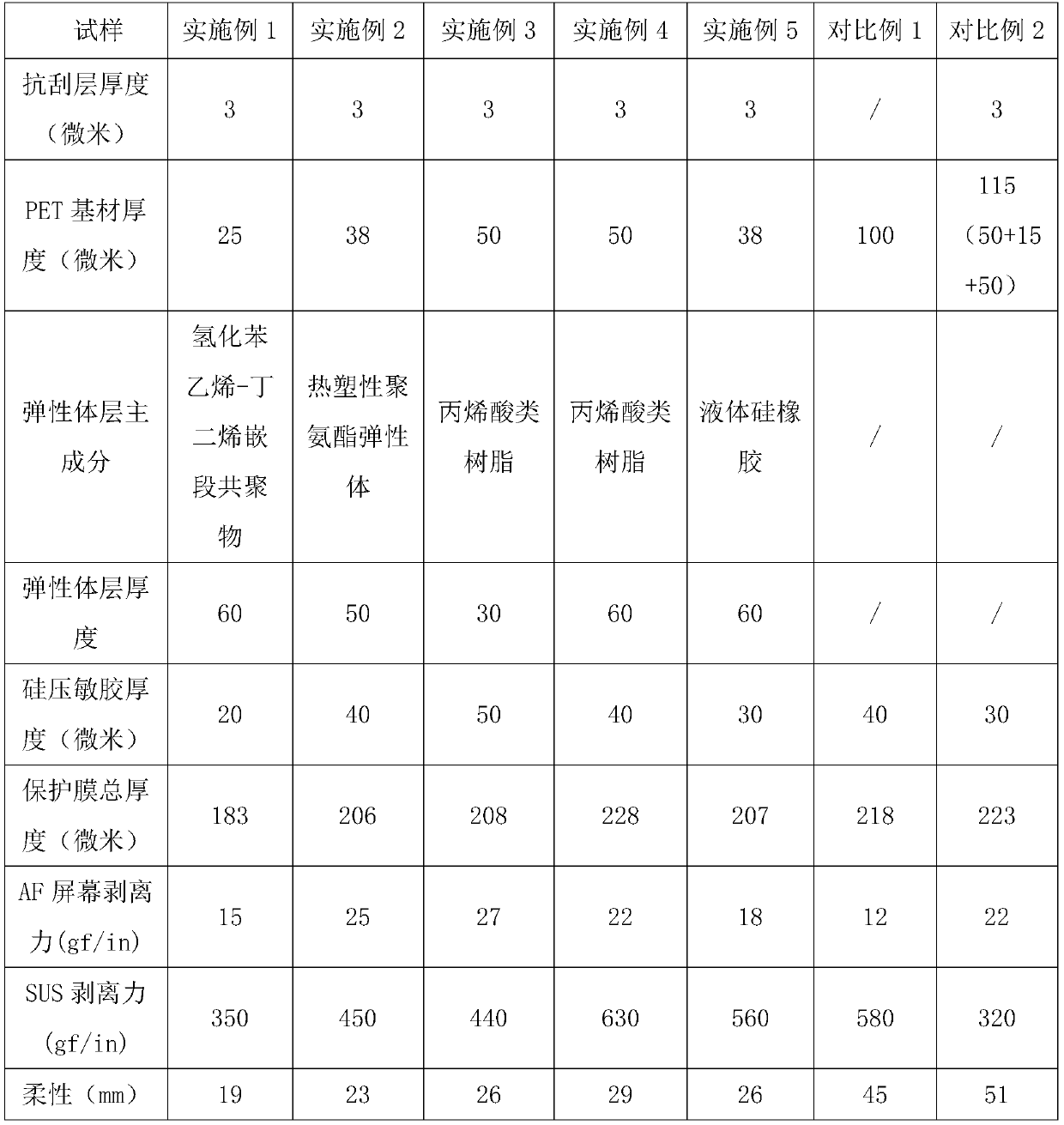

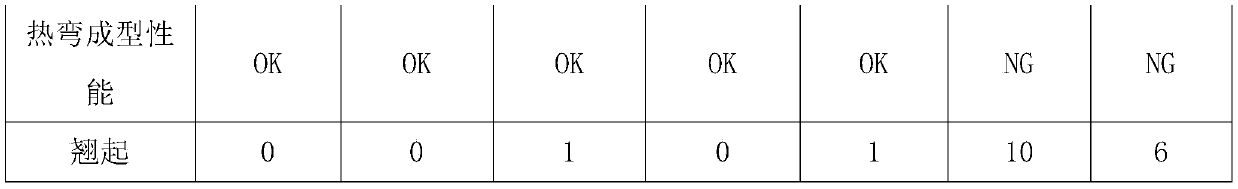

Embodiment 1

[0031] A curved screen protective film, comprising a scratch-resistant layer, a PET base material, an elastomer layer, a silica gel layer, and a fluorine release film arranged in sequence; the thickness of the PET base material is 25 microns, and the thickness of the elastomer layer is 60 microns, the thickness of the silica gel layer is 20 microns, the thickness of the scratch-resistant layer is 3 microns, and the thickness of the fluorine release film is 75 microns; the silica gel layer is a silicone pressure-sensitive adhesive layer; the fluorine The plain release film is a PET substrate coated with a fluorine release agent; the elastomer layer includes a hydrogenated styrene-butadiene block copolymer.

[0032] The anti-scratch layer mainly adopts ultraviolet curable coatings, and the raw material components of the coatings are: 50 parts of hexafunctional aliphatic urethane acrylate, 20 parts of dipentaerythritol hexaacrylate, 3 parts of anti-fingerprint coating additives, p...

Embodiment 2

[0041] A curved screen protective film, comprising a scratch-resistant layer, a PET base material, an elastomer layer, a silica gel layer, and a fluorine release film arranged in sequence; the thickness of the PET base material is 38 microns, and the thickness of the elastomer layer is 50 microns, the thickness of the silica gel layer is 40 microns, the thickness of the scratch-resistant layer is 3 microns, and the thickness of the fluorine release film is 75 microns; the silica gel layer is a silicone pressure-sensitive adhesive layer; the fluorine The plain release film is a PET substrate coated with a fluorine release agent; the elastomer layer includes thermoplastic polyurethane elastomer.

[0042] The anti-scratch layer mainly adopts ultraviolet curable coatings, and the raw material components of the coatings are: 60 parts of hexafunctional aliphatic urethane acrylate, 30 parts of dipentaerythritol hexaacrylate, 5 parts of anti-fingerprint coating additives, photoinitiate...

Embodiment 3

[0051] A curved screen protective film, comprising a scratch-resistant layer, a PET substrate, an elastomer layer, a silica gel layer, and a fluorine release film that are sequentially structured; the thickness of the PET substrate is 50 microns, and the thickness of the elastomer layer is The thickness of the silica gel layer is 50 microns, the thickness of the scratch-resistant layer is 3 microns, and the thickness of the fluorine release film is 75 microns; the silica gel layer is a silicone pressure-sensitive adhesive layer; the The fluorine release film is a PET substrate coated with a fluorine release agent; the elastomer layer includes acrylic resin.

[0052] The anti-scratch layer mainly adopts ultraviolet curable coatings, and the raw material components of the coatings are: 70 parts of hexafunctional aliphatic urethane acrylate, 40 parts of dipentaerythritol hexaacrylate, 8 parts of anti-fingerprint coating additives, photoinitiated 10 parts of solvent and 30 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com