Hydrophobic film-coating liquid and production process of anti-pollution anti-fingerprint film-coated layer prepared therefrom

A coating liquid, anti-fingerprint technology, applied in the device, coating, pretreatment surface, etc. of the surface coating liquid, can solve the problems of weak van der Waals force, drop, poor adhesion of the substrate, etc., to achieve good hydrophobic performance , Improve adhesion, good anti-fouling and anti-fingerprint performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A hydrophobic coating solution, comprising: 100 parts by mass of fluorosilicone, 0.1-0.5 parts by mass of perfluoropolyether, 1-20 parts by mass of distilled water or deionized water, 10-50 parts by mass of alcohol, and 0.1-2 parts by mass of inorganic acid parts by mass. The chemical structural formula of described fluorosilicone is CF3-CF2-CF2-CF2-CF2-O-Si-(OCH3)3; The chemical structural formula of described perfluoropolyether is CF3-O-(CF2-O-CF2- CF2-O)n-CF 3 ; The alcohol is methanol; The inorganic acid is hydrochloric acid.

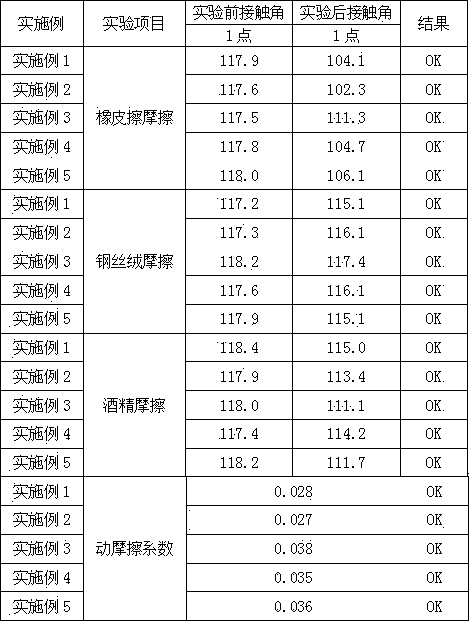

[0021] To this end, the inventor has done a large number of experiments, and the specific experimental data of the contents of each component of the hydrophobic coating solution are shown in the table below:

[0022] Fluorosilicone Perfluoropolyether Deionized water Methanol hydrochloric acid Example 1 100 parts by mass 0.1 parts by mass 1 part by mass 10 parts by mass 0.1 parts by mass Example 2 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com