Anti-fingerprint agent, and method and product applying the same to conduct surface treatment

An anti-fingerprint agent and surface treatment technology, which is applied in the field of anti-fingerprint agents, can solve problems such as poor binding force and difficult film formation of polytetrafluoroethylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

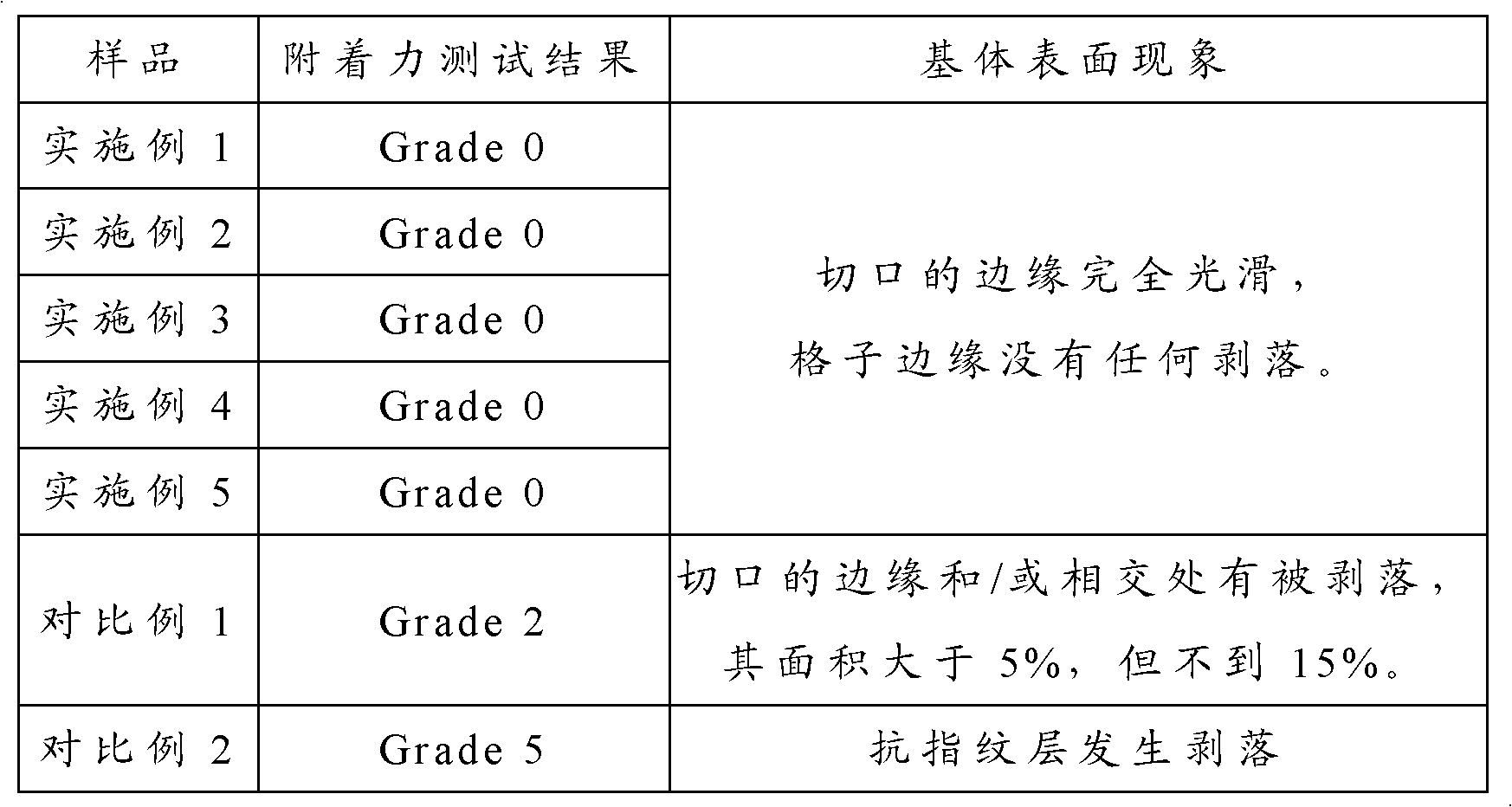

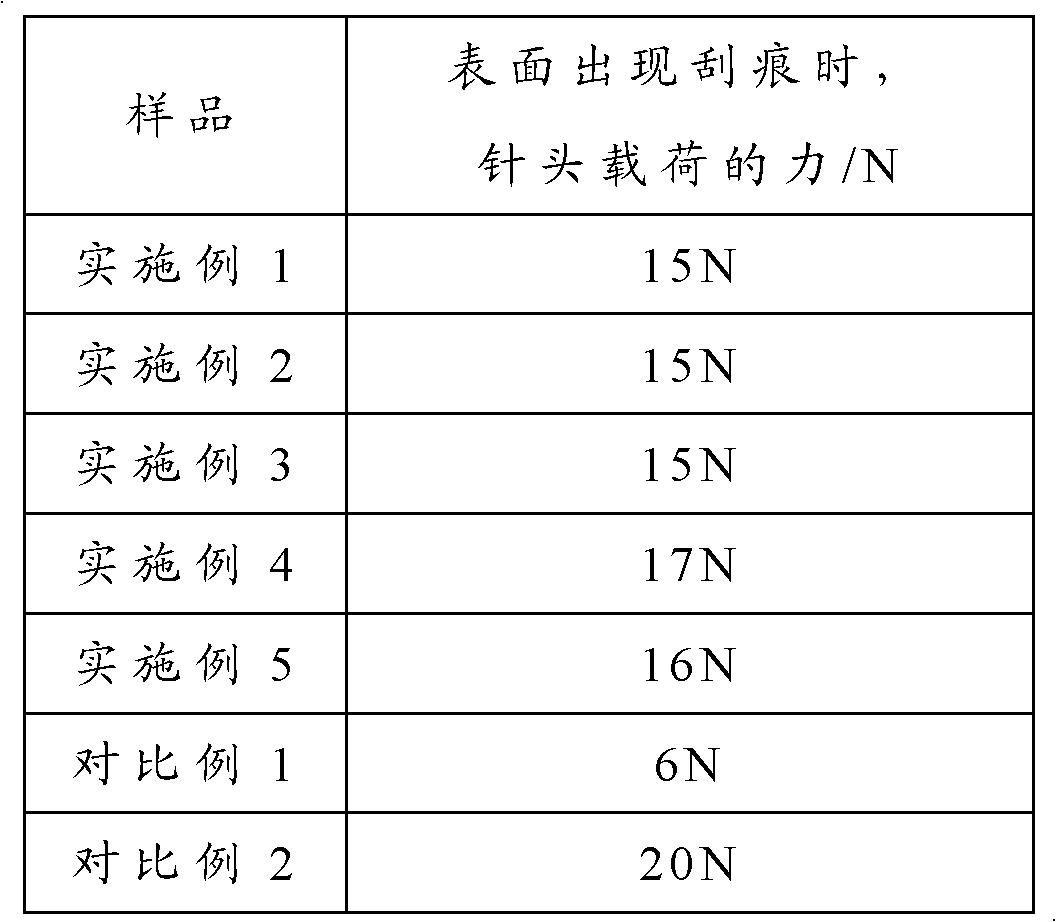

Examples

Embodiment 1

[0028] A substrate is provided, on which a chromium carbide layer and a titanium nitride layer are sequentially formed. Both the chromium carbide layer and the titanium nitride layer are formed by vacuum coating.

[0029] Preparation of anti-fingerprint agent: provide a silane solution. The silane solution mainly consists of methyltriethoxysilane, ethyl orthosilicate, absolute ethanol, deionized water and dilute sulfuric acid. Wherein, the volume percentage of methyltriethoxysilane is 60%, the volume percentage of ethyl orthosilicate is 2%, the volume percentage of absolute ethanol is 2%, the volume percentage of deionized water is 25% and The volume percentage of dilute sulfuric acid is 5%. The mass percent content of dilute sulfuric acid used to configure the silane solution is 45%.

[0030] Mix the liquid polytetrafluoroethylene and the silane solution at a volume ratio of 0.6:1 to prepare a mixed solution, stir evenly and let stand for 30 minutes; after that, filter the...

Embodiment 2

[0033] A substrate is provided, which is the same as that provided in Example 1.

[0034] Preparation of anti-fingerprint agent: provide a silane solution. The silane solution mainly consists of methyltriethoxysilane, ethyl orthosilicate, absolute ethanol, deionized water and dilute sulfuric acid. Wherein, the volume percentage of methyltriethoxysilane is 63%, the volume percentage of ethyl orthosilicate is 3%, the volume percentage of absolute ethanol is 3%, the volume percentage of deionized water is 26.5% and The volume percentage of dilute sulfuric acid is 9%. The mass percent content of dilute sulfuric acid used to configure the silane solution is 45%.

[0035] Mix the liquid polytetrafluoroethylene and the silane solution at a volume ratio of 0.8:1 to prepare a mixed solution, stir evenly and let stand for 40 minutes; after that, filter the mixed solution to remove a small amount of suspended impurities to obtain the anti-fingerprint agent.

[0036] Forming an anti-f...

Embodiment 3

[0038] An anti-fingerprint layer was formed on the substrate in the same manner as in Example 2, except that a zirconium nitride layer was formed on the substrate instead of the chromium carbide layer and titanium nitride layer. The zirconia layer is formed by vacuum coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com