UV photo-curing composition additive and preparation method thereof

A technology of additives and compositions, which is applied in the field of UV light-curing composition additives and its preparation, can solve the problems of waterproof, oil-proof, hardness, and unsatisfactory friction resistance of the protective film, achieve good flexibility, and reduce the coefficient of dynamic friction , improve the waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

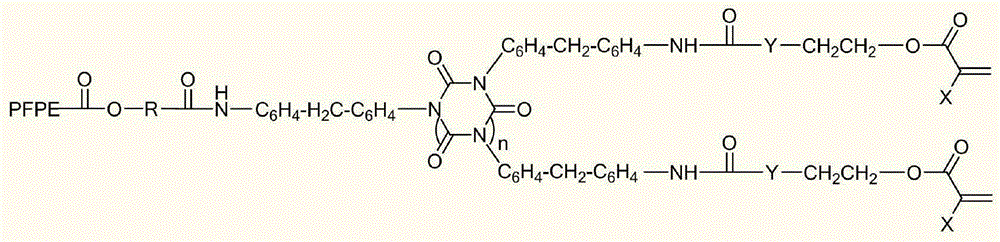

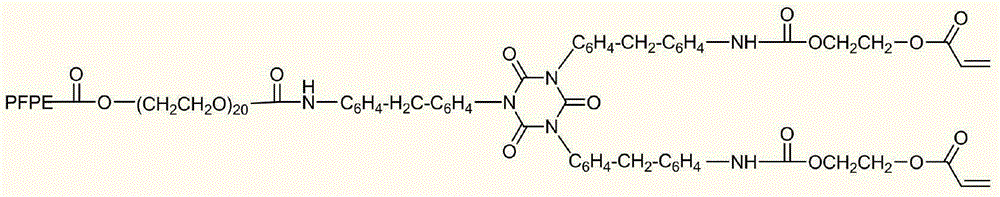

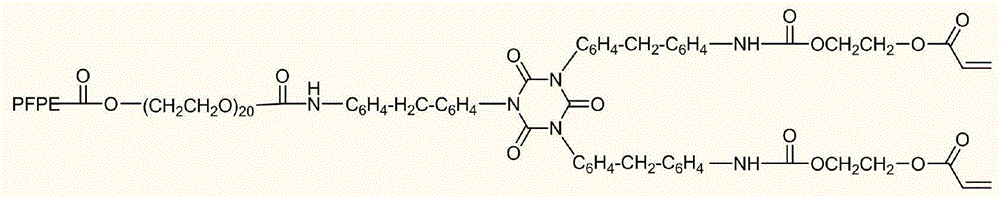

Image

Examples

preparation example Construction

[0083] A kind of preparation method of UV photocurable composition additive, is characterized in that comprising following preparation steps:

[0084] a) adding the crosslinking agent iii), catalyst and solvent A into a three-necked flask, fully stirring the above solution evenly, and heating to the reaction temperature;

[0085] b) adding a mixture of perfluoropolyether i) and solvent A to the three-necked flask under stirring to obtain a mixed solution;

[0086] c) reacting the mixed solution at the reaction temperature for 4-10 hours;

[0087] d) adding the mixture of monomer ii) and solvent B into the three-necked flask under stirring, and reacting at the reaction temperature for 10-15h;

[0088] e) After the reaction, the mixture was cooled to room temperature and diluted with solvent B to 20% solid content.

[0089] The catalyst in step a) is an organic tin, organic aluminum, organic antimony compound, preferably an organic tin compound, more preferably dibutyltin dila...

Embodiment 1~12

[0117] Table 4 Perfluoropolyether i) used in Examples 1 to 12

[0118]

[0119] The structural formula of perfluoropolyether i) is PFPE-C(O)O-R-H

[0120] Table 5 embodiment 1~12 reaction conditions

[0121]

[0122]

[0123] Table 6 Examples 1-12 and Comparative Examples 1-3 are cured to form various properties of the film

[0124]

[0125]

[0126] List embodiment 1-12 and comparative example 1-3 coating performance test result in table 6, the result shows that after adopting UV photocurable composition additive of the present invention to cure, performance is superior in: compared with comparative example 1-3, because The coordination between the polyether polyol structure and other components, especially the coordination between the perfluoropolyether, endows the coating with a higher water contact angle and oil contact angle, after the UV light-curable composition additive is cured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com