Titanium-base composite material and manufacturing method thereof

A technology of titanium-based composite materials and manufacturing methods, which is applied in the direction of metal material coating technology, electrolytic coating, thin material treatment, etc., can solve the problems of easy residual fingerprints and affect the appearance effect, and achieve good anti-fingerprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Referring to the accompanying drawings, the titanium-based composite material and manufacturing method of the present invention will be described in detail below.

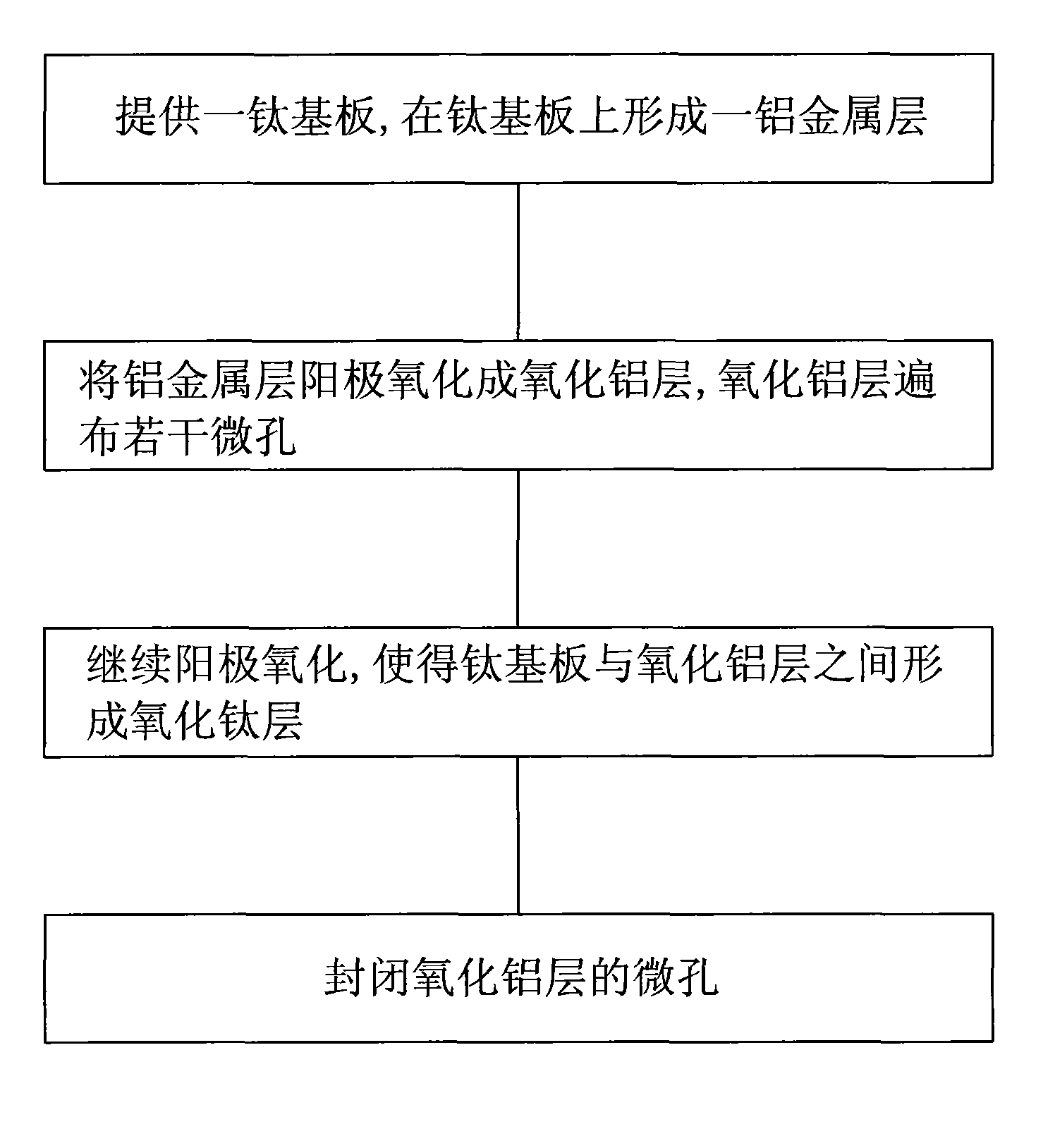

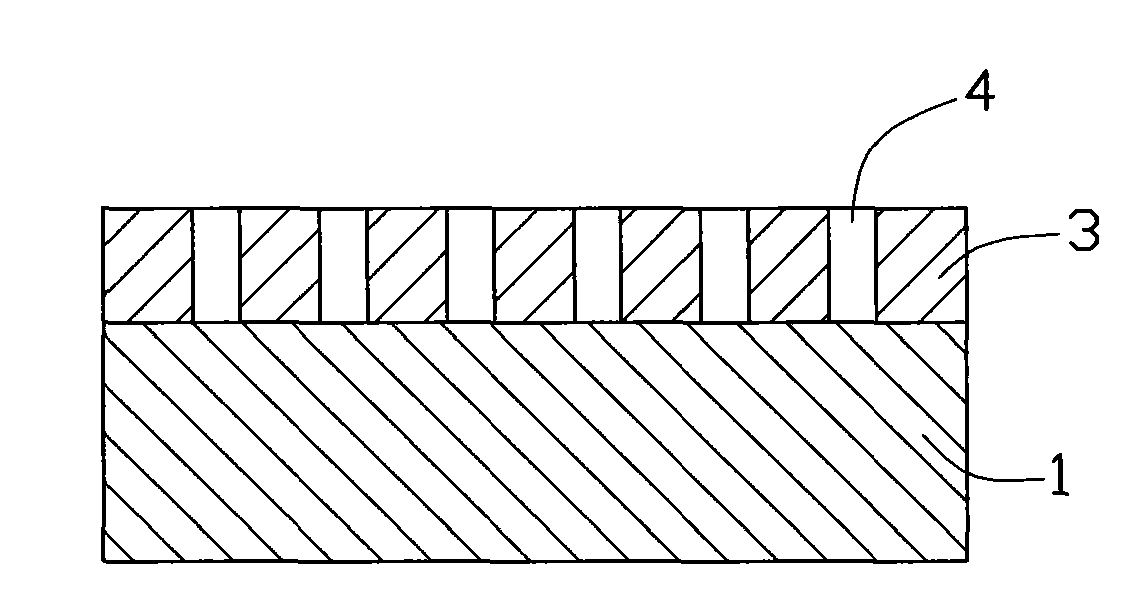

[0013] Such as Figure 5 As shown, the titanium-based composite material includes a titanium substrate 1 , a titanium oxide layer 5 and an aluminum oxide layer 3 . The titanium substrate 1 is titanium metal or titanium alloy, the titanium oxide layer 5 covers the titanium substrate 1 , and the aluminum oxide layer 3 is located on the titanium oxide layer 5 . Preferably, the aluminum oxide layer 3 is colorless and transparent.

[0014] Such as figure 1 Shown, the manufacture method of titanium-based composite material of the present invention comprises the following steps:

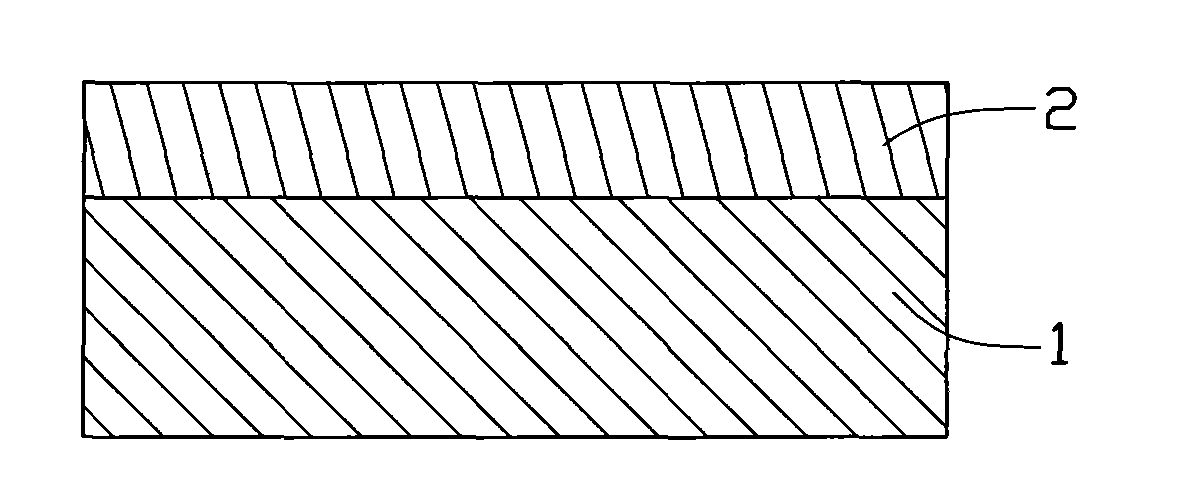

[0015] First, if figure 2 As shown, a titanium substrate 1 is provided. The titanium substrate 1 is titanium metal or titanium alloy. An aluminum metal layer 2 is formed on the titanium substrate 1. The method for forming the aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com