Fermenting device and straw biogas system

A fermentation device and straw technology, applied in the direction of gas production bioreactors, biochemical instruments, waste fuels, etc., can solve the problems of difficult discharge and exhaustion of biogas residues, complex structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

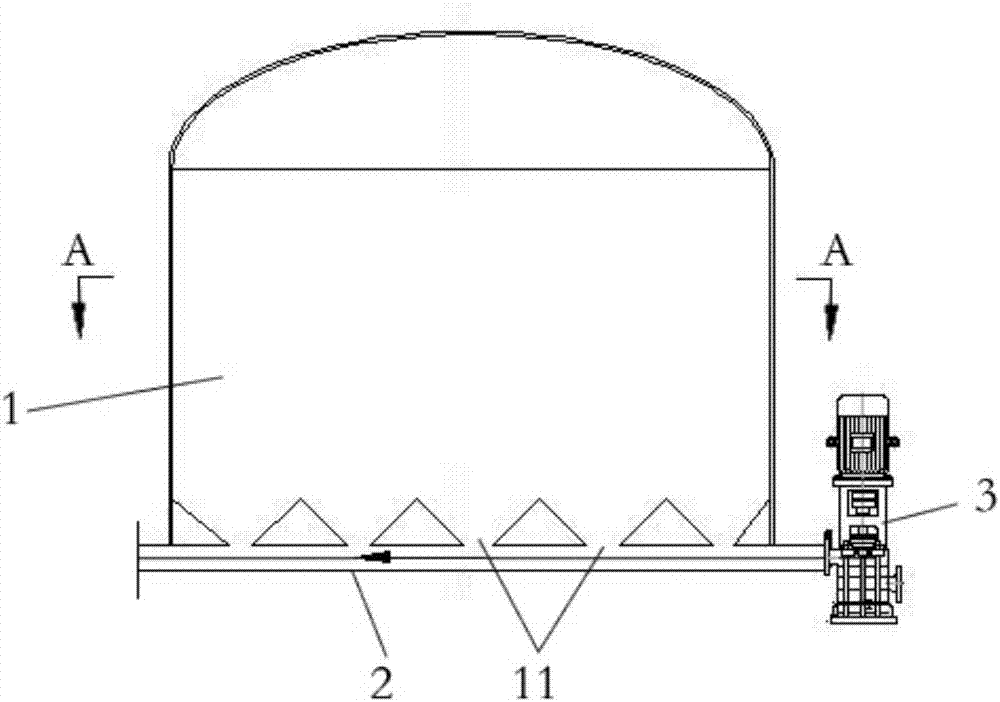

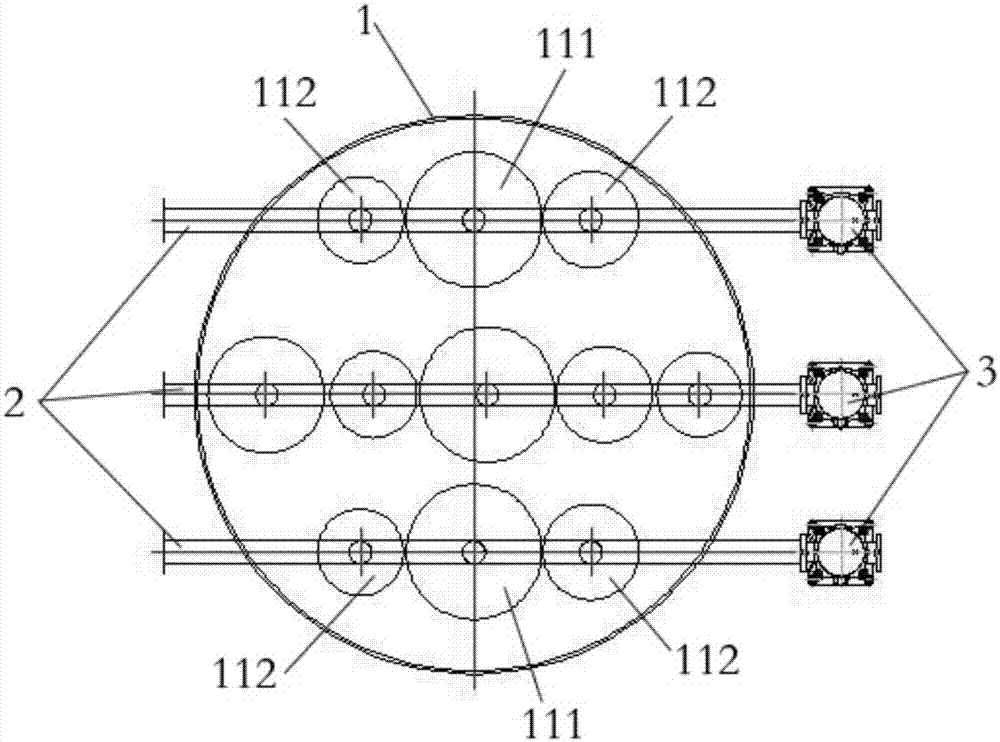

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0025] In the present invention, in the case of no contrary description, the used orientation words such as "up, down, left and right" usually refer to the up, down, left and right shown in the accompanying drawings; "inside and outside" It refers to the inside and outside with respect to the outline of each part itself.

[0026] It is difficult to discharge the biogas residue in the existing dry-type straw fermentation device, and generally the biogas residue cannot be exhausted, which is not conducive to subsequent feeding, and also has a certain impact on the continuous gas production, or the structure of the slag discharge part of the fermentation device is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com