Method for improving powder falling of dental gypsum

A technology of dental plaster and gypsum powder, applied in the field of dental gypsum powder, can solve the problems of not mentioning dental gypsum and printing film material, dental gypsum model products are uneven, and dental gypsum and printing film material drop powder, etc., and achieve clinical application effect. Good, increase the inter-strength, the effect of adding a small amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

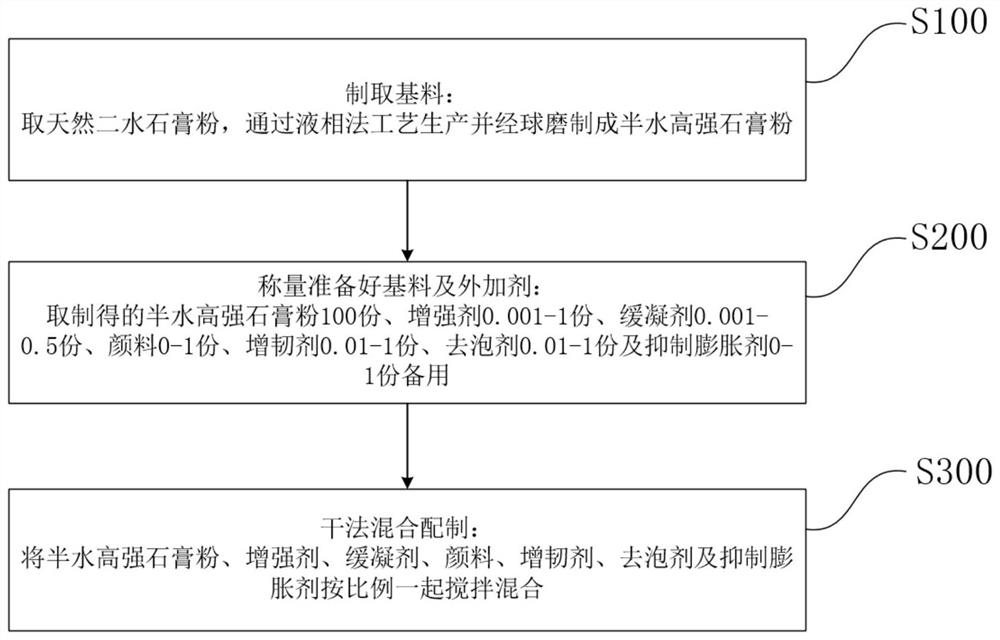

Method used

Image

Examples

Embodiment 1

[0027] Take 100 parts of the prepared semi-water high-strength gypsum powder, 1 part of reinforcing agent, 0.5 part of setting retarder, 1 part of pigment, 1 part of toughening agent, 1 part of defoaming agent and 1 part of expansion inhibitor for later use. Among them, the strengthening agent is sulfonated melamine formaldehyde resin, the retarder is citric acid retarder, the pigment is iron yellow, the toughening agent is polymer resin, the defoaming agent is mineral oil, and the expansion inhibitor is silicate kind. Stir and mix the semi-hydrated high-strength gypsum powder, reinforcing agent, retarder, pigment, toughening agent, defoamer and expansion inhibitor in proportion. Wherein, when stirring and mixing, the mixer is first turned on, and then the semi-water high-strength gypsum powder is gradually transported into the mixer for stirring. When the amount of semi-hydrated high-strength gypsum powder delivered to the mixer reaches half, gradually add reinforcing agent,...

Embodiment 2

[0029] Take 100 parts of the prepared semi-water high-strength gypsum powder, 0.001 part of reinforcing agent, 0.001 part of setting retarder, 0.01 part of toughening agent and 0.01 part of defoaming agent for later use. Among them, the strengthening agent is lignin water reducer, the retarder is phosphate retarder, the toughening agent is vinyl acetate, and the defoaming agent is polyether modified polysiloxane. Stir and mix the semi-water high-strength gypsum powder, reinforcing agent, retarder, toughening agent and defoamer in proportion. Wherein, when stirring and mixing, the mixer is first turned on, and then the semi-water high-strength gypsum powder is gradually transported into the mixer for stirring. When the amount of semi-water high-strength gypsum powder delivered to the mixer reaches half, gradually add reinforcing agent, retarder, toughener and defoamer to the semi-water high-strength gypsum powder in the mixer. The process of water high-strength gypsum powder b...

Embodiment 3

[0031]Take 100 parts of the obtained semi-water high-strength gypsum powder, 0.5 parts of reinforcing agent, 0.3 parts of setting retarder, 0.4 parts of pigment, 0.5 parts of toughening agent, 0.4 parts of defoaming agent and 0.5 parts of expansion inhibitor for later use. Among them, the strengthening agent is a mixture of polycarboxylate water reducer and Nai series water reducer, the retarder is a mixture of bone glue retarder and phosphate retarder, the pigment is titanium dioxide, and the toughening The antifoaming agent is a mixture of three kinds of vinyl acetate, polyvinyl alcohol and acrylic acid, the defoaming agent is a mixture of alcohols and organic silicon, and the expansion inhibitor is tartrate. Stir and mix the semi-hydrated high-strength gypsum powder, reinforcing agent, retarder, pigment, toughening agent, defoamer and expansion inhibitor in proportion. Wherein, when stirring and mixing, the mixer is first turned on, and then the semi-water high-strength gyp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com