Preparation method of solid state lithium ion batteries

A lithium-ion battery, solid-state technology, applied in electrolyte battery manufacturing, electrode manufacturing, secondary battery and other directions, can solve the problems of expensive magnetron sputtering equipment, affecting battery performance, poor interface performance, etc., to improve electrochemical performance , Improve the interface performance, the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

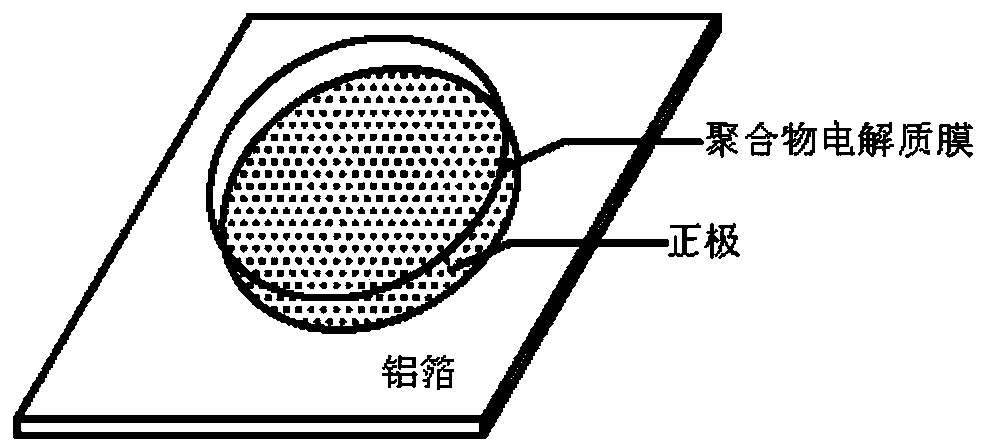

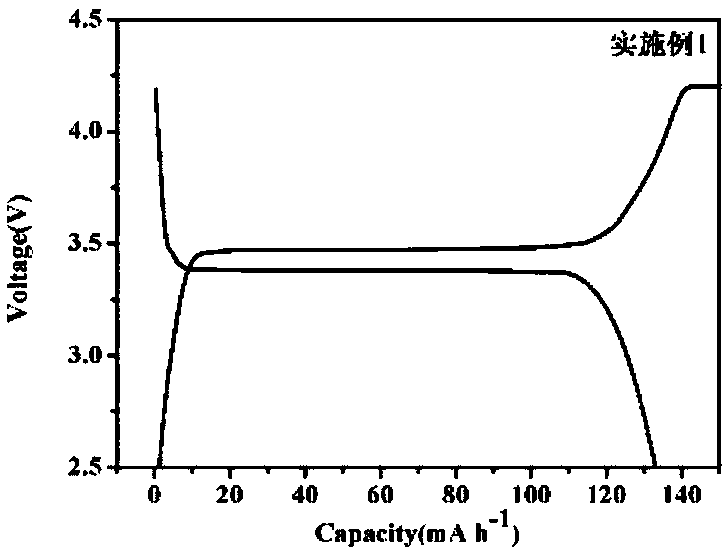

Embodiment 1

[0037] Preparation of the positive electrode sheet: the positive electrode active material LiFePO 4 , the conductive agent Super-P and KS-6, and the binder PVDF were added to the solvent NMP at a ratio of 89:6:5, and mixed for 150 minutes to make a positive electrode slurry. The positive electrode slurry was printed on the positive electrode by screen printing. On the aluminum foil of the current collector, after drying at 95°C, press the sheet with a roller press to prepare the positive electrode sheet of the lithium-ion battery. The screen printing machine is a 45cm×60cm manual screen printing machine, and the screen is 200 mesh and the area is It is a 40cm×50cm screen.

[0038] Preparation of polymer electrolyte membrane: Polyethylene oxide PEO, lithium salt LiPF in a vacuum glove box 6 , Nano inorganic oxide Al 2 o 3 , Ethyl cellulose was added to the solvent DMF in the ratio of 56:7:9:28, and after mixing for 150 minutes, a milky white slurry was obtained. The slurry w...

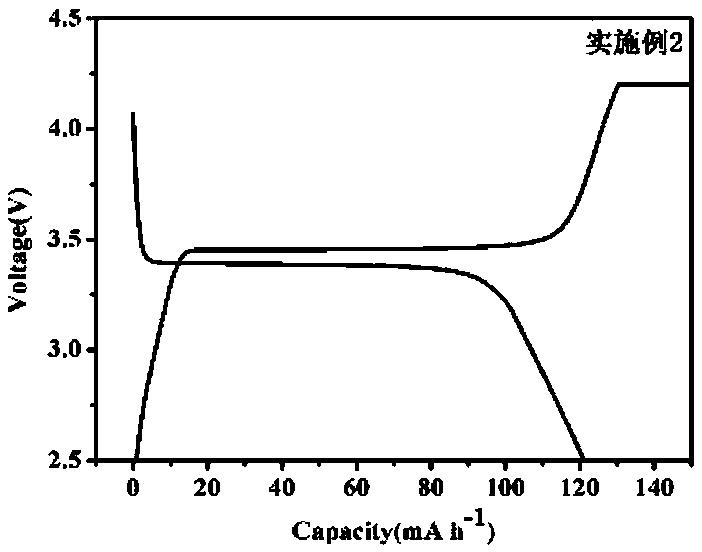

Embodiment 2

[0041] Preparation of the positive electrode sheet: the positive electrode active material LiFePO 4 , the conductive agent Super-P and KS-6, and the binder PVDF were added to the solvent NMP in a ratio of 89:6:5, and mixed for 120 minutes to make a positive electrode slurry, and the positive electrode slurry was printed on the positive electrode by screen printing. The aluminum foil of the current collector was dried at 95° C., and then pressed with a roller press to prepare the positive electrode sheet of the lithium-ion battery.

[0042] Preparation of polymer electrolyte membrane: Polyethylene oxide PEO, lithium salt LiPF in a vacuum glove box 6 , Nano inorganic oxide Al 2 o 3 , Ethyl cellulose was added to the solvent DMF according to the ratio of 58:5:9:28, and after mixing for 120 minutes, a milky white slurry was obtained, and the slurry was printed on the positive electrode sheet in the previous step by screen printing method. After drying, the polymer electrolyte m...

Embodiment 3

[0045] Preparation of the positive electrode sheet: the positive electrode active material LiFePO 4, the conductive agent Super-P and KS-6, and the binder PVDF were added to the solvent NMP at a ratio of 85:10:5, and mixed for 120 minutes to make a positive electrode slurry. The positive electrode slurry was printed on the positive electrode by screen printing. The aluminum foil of the current collector was dried at 95° C., and then pressed with a roller press to prepare the positive electrode sheet of the lithium-ion battery.

[0046] Preparation of polymer electrolyte membrane: Polyethylene oxide PEO, lithium salt LiPF in a vacuum glove box 6 , Nano inorganic oxide Al 2 o 3 , Ethyl cellulose was added to the solvent DMF in the ratio of 56:7:9:28, and the milky white slurry was obtained after mixing for 120 minutes. The slurry was printed on the positive electrode sheet in the previous step by screen printing method. After drying, the polymer electrolyte membrane / positive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com