Layered coating type scratch-resistant coating reflecting film and preparation method thereof

A reflective film and scratch-resistant technology, applied in the field of optical reflective film, can solve the problems affecting scratch resistance and anti-adsorption performance, and achieve the improvement of scratch resistance and anti-adsorption, reduce viscosity, and improve film surface quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

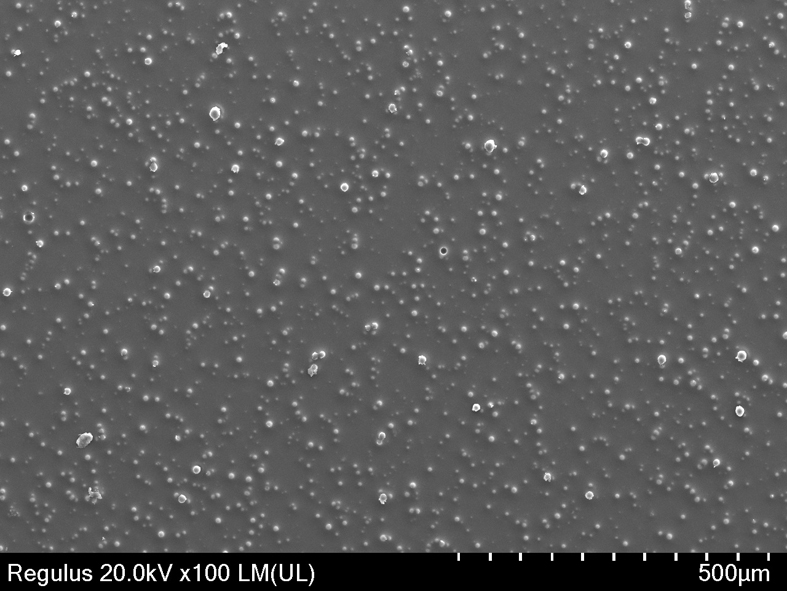

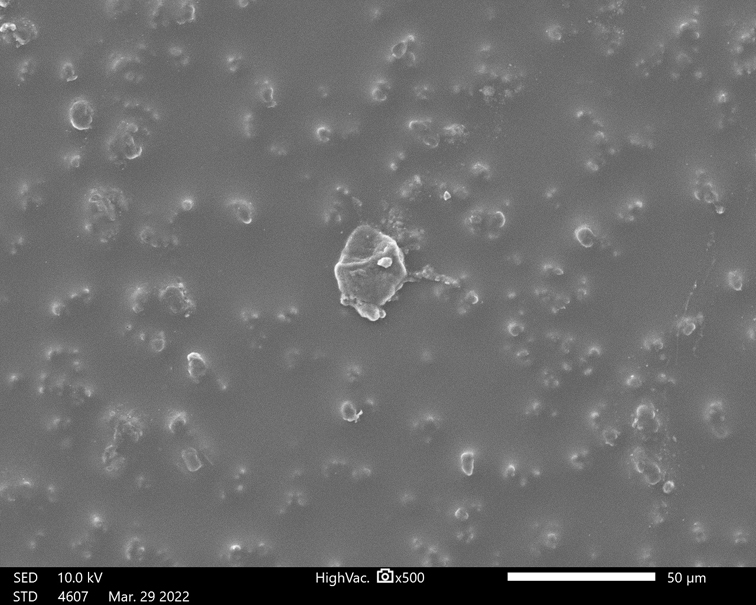

Image

Examples

Embodiment 1

[0033] A layered coating type scratch-resistant coating reflective film, the preparation method is:

[0034] (1) Preparation of low-viscosity mixed adhesive layer coating liquid: In mass percent, the components of the mixed adhesive layer coating liquid include: 10% polyacrylate adhesive, 20% silicone resin adhesive, 1% curing agent, 1% silane coupling agent, 68% ethyl acetate solvent; during preparation, add polyacrylate adhesive and silicone resin adhesive to the solvent, stir and disperse evenly, then add curing agent and silane coupling agent, and stir evenly. A mixed adhesive layer coating liquid with a viscosity of 15cps was obtained;

[0035] (2) Preparation of high-viscosity elastic particle layer coating liquid: In terms of mass percentage, the components of the elastic particle layer coating liquid include: 20% PMMA particles, 15% polyacrylate adhesive, 1% dispersant, 1.5% curing agent, 62.5% ethyl acetate solvent; add the polyacrylate adhesive to the solvent during...

Embodiment 2

[0038] A layered coating type scratch-resistant coating reflective film, the preparation method is:

[0039](1) Preparation of low-viscosity mixed adhesive layer coating liquid: In terms of mass percentage, the components of the mixed adhesive layer coating liquid include: 10% polyacrylate adhesive, 30% silicone resin adhesive, 1% curing agent, 1.5% silane coupling agent, 0.5% antistatic agent, 57% ethyl acetate solvent; when preparing, add polyacrylate adhesive and silicone resin adhesive to the solvent, stir and disperse evenly, then add antistatic agent, The curing agent and the silane coupling agent are uniformly stirred to obtain a mixed adhesive layer coating liquid with a viscosity of 12cps;

[0040] (2) Preparation of high-viscosity elastic particle layer coating liquid: In terms of mass percentage, the components of the elastic particle layer coating liquid include: 20% polyurethane particles, 15% polyacrylate adhesive, 1% dispersant, 1.5% curing agent, 62.5% ethyl a...

Embodiment 3

[0043] A layered coating type scratch-resistant coating reflective film, the preparation method is:

[0044] (1) Preparation of low-viscosity mixed adhesive layer coating liquid: In mass percent, the components of the mixed adhesive layer coating liquid include: 10% polyacrylate adhesive, 20% silicone resin adhesive, 0.5% Static agent, 1% curing agent, 1% silane coupling agent, 67.5% ethyl acetate solvent; when preparing, add polyacrylate adhesive and silicone resin adhesive to the solvent, stir and disperse evenly, then add antistatic agent, The curing agent and the silane coupling agent are uniformly stirred to obtain a mixed adhesive layer coating liquid with a viscosity of 15cps;

[0045] (2) Preparation of high-viscosity elastic particle layer coating liquid: In terms of mass percentage, the components of the elastic particle layer coating liquid include: 30% PMMA particles, 15% polyacrylate adhesive, 1% dispersant, 1.5% curing agent, 52.5% ethyl acetate solvent; add the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com