Glaze covering device for use in ceramic tile blank glaze showering and method thereof

A ceramic tile and glazing technology, which is applied in the field of ceramic tile glazing process and equipment, can solve the problems of short service life of rollers, defects of brick bottoms, high consumption of glaze slurry, etc., so as to reduce production costs, reduce loss and improve production efficiency and quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] At first, explain the inventive thought:

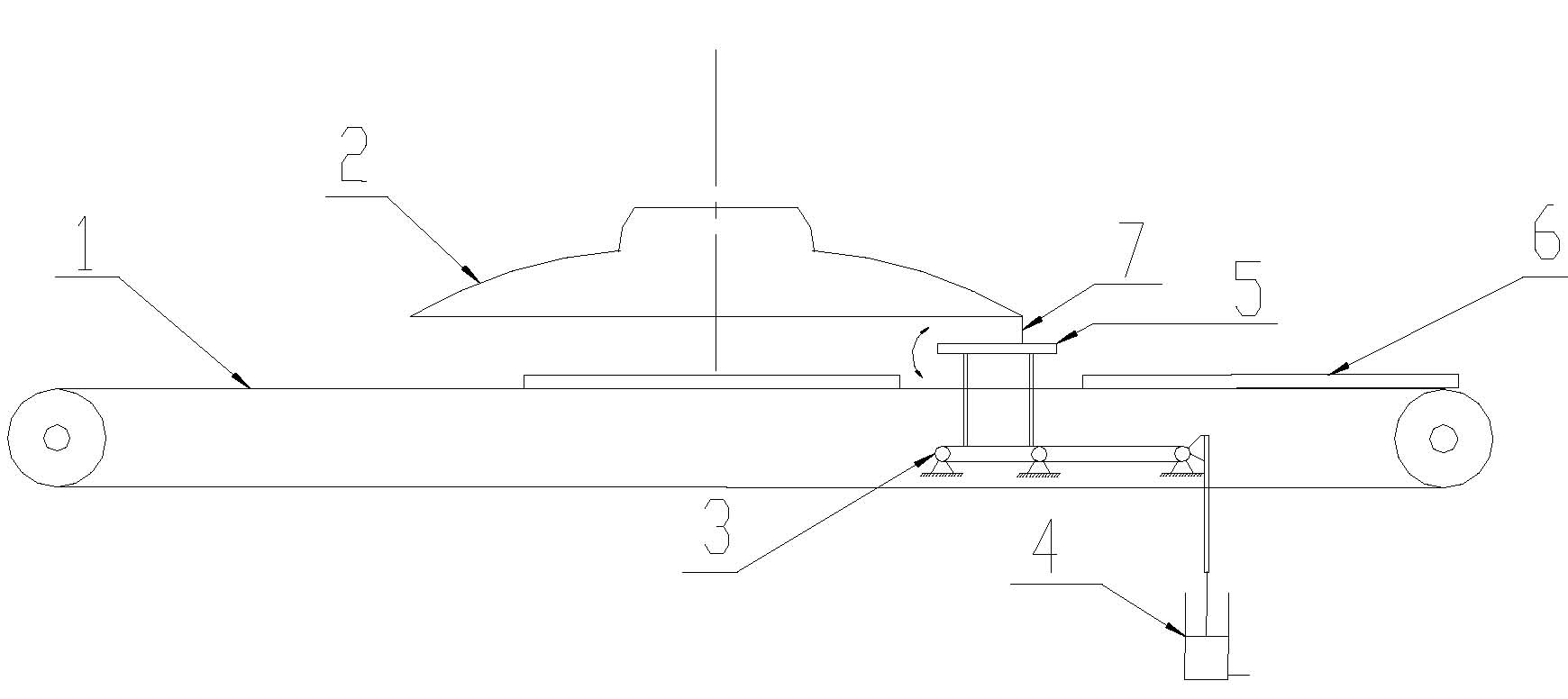

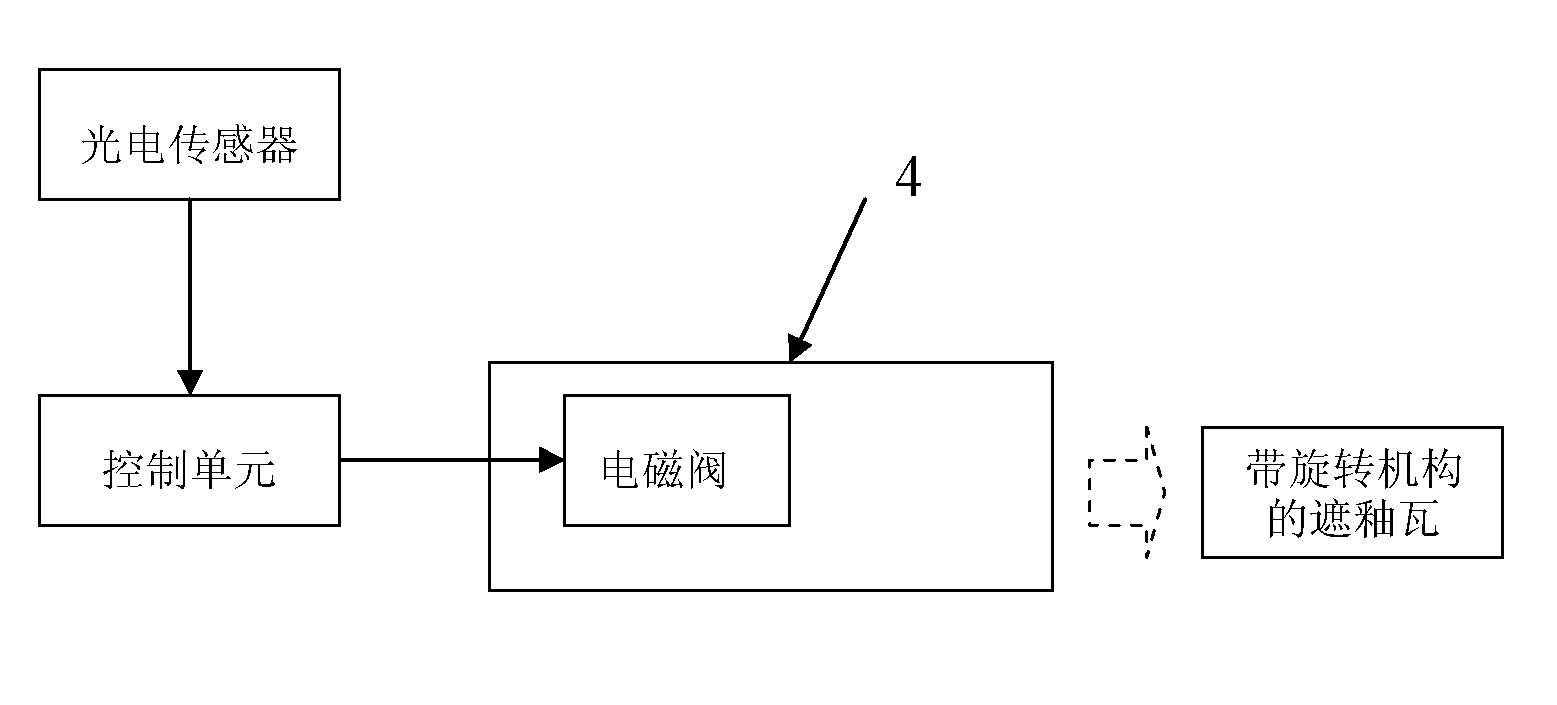

[0024] The glaze pouring method of the ceramic tile body of the present invention is to drive the glaze slurry into the high-level tank through the pressure pump, and the glaze slurry passes through the buffering effect of the lower size pipe, the buffer tank and the buffer net, and the glaze slurry gently overflows and flows to the bell jar, and the glaze slurry flows out in the bell jar A waterfall-like glaze curtain is formed on the spread, (1) when the ceramic tile passes through, the glaze curtain is covered on the tile to form a glaze layer in accordance with the traditional method; but when the continuously formed glaze curtain (2) passes through without the tile, it is improved, Automatically close the barrier above the belt, the glaze slurry is blocked and does not cover the conveyor belt, and falls into the glaze tank for recycling into the glaze bucket for recycling.

[0025] Next, explain the key of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com