Water treatment device capable of scraping membrane surface sludge

A water treatment device and sludge technology, applied in osmotic/dialysis water/sewage treatment, membrane technology, semi-permeable membrane separation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

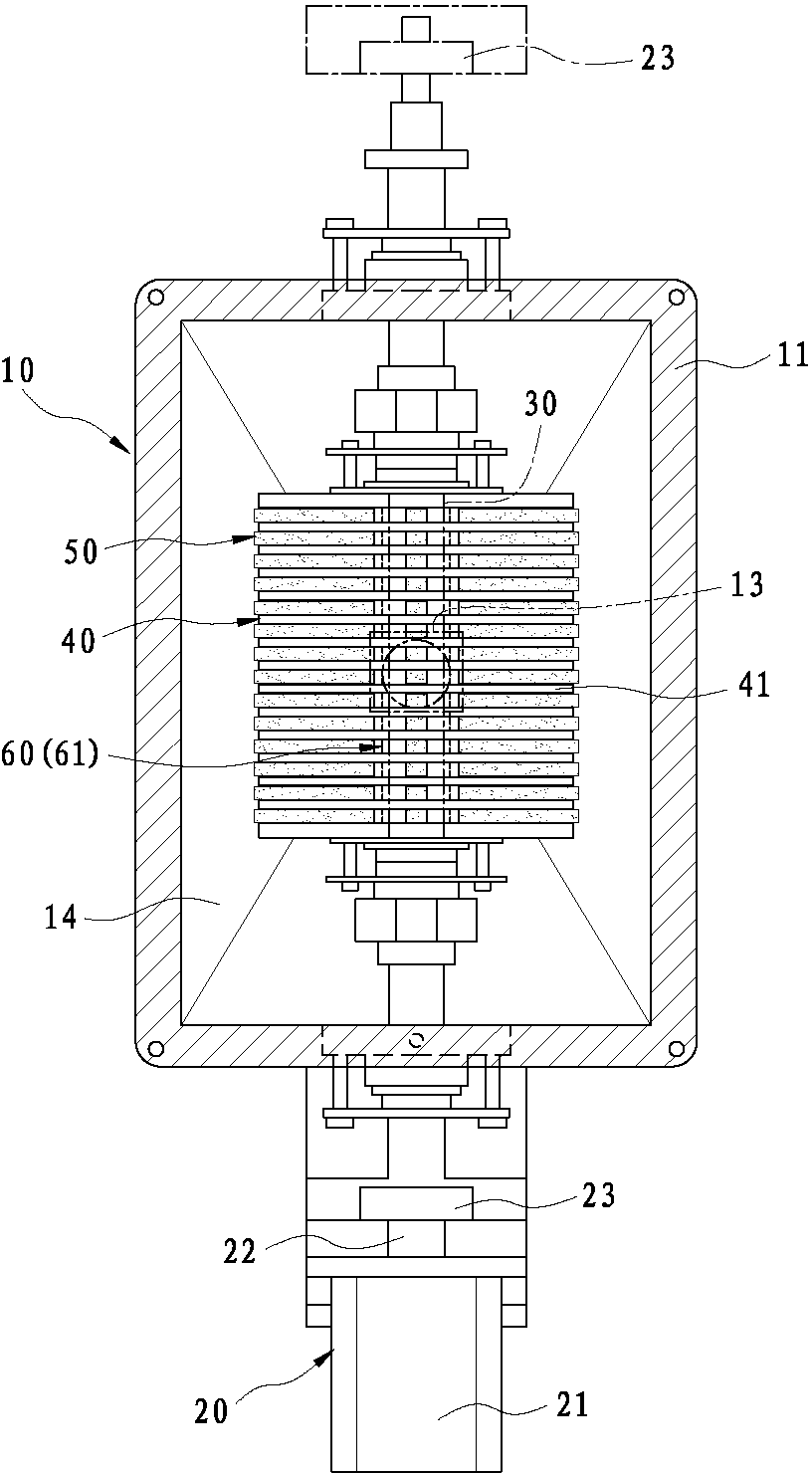

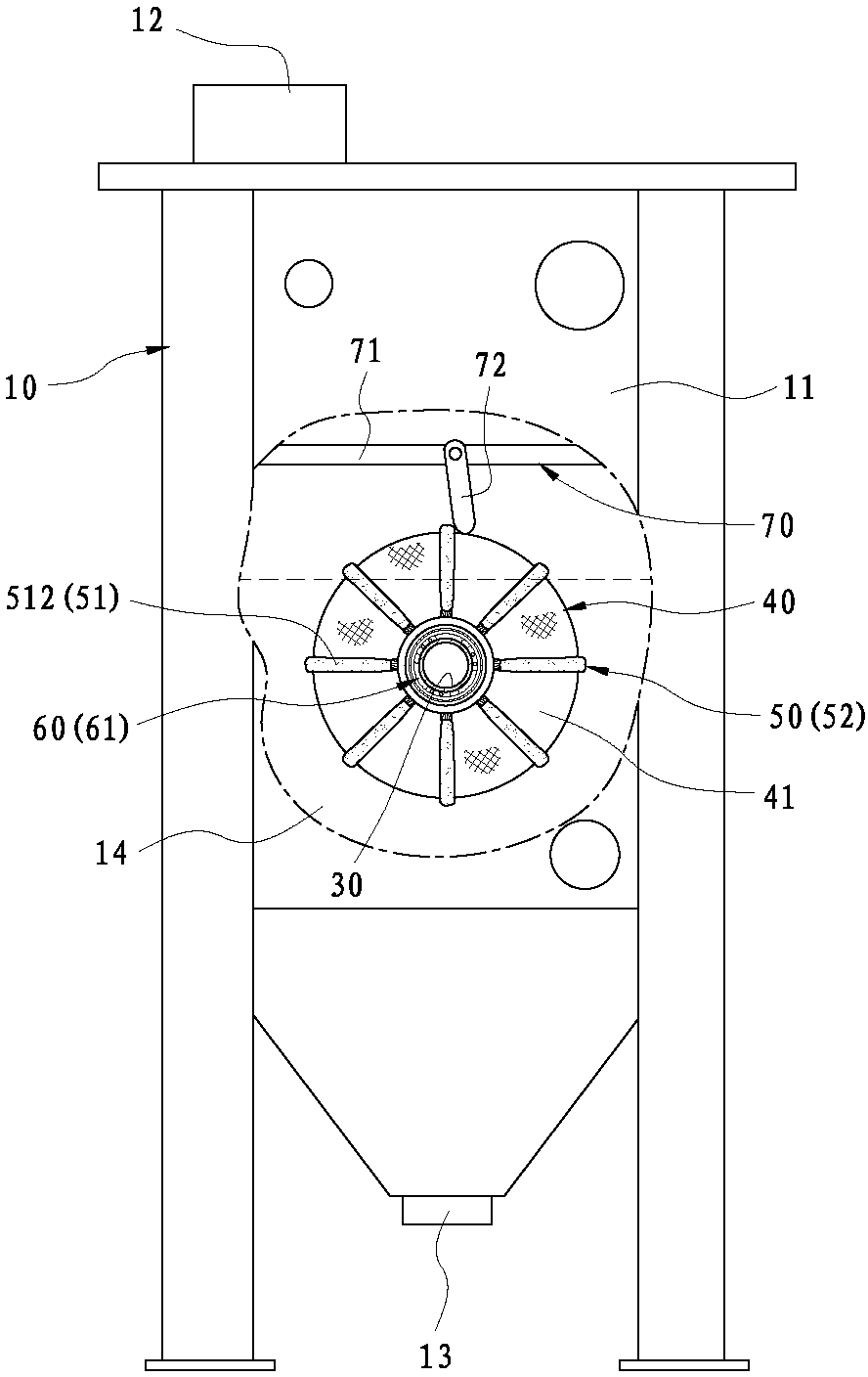

[0027] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

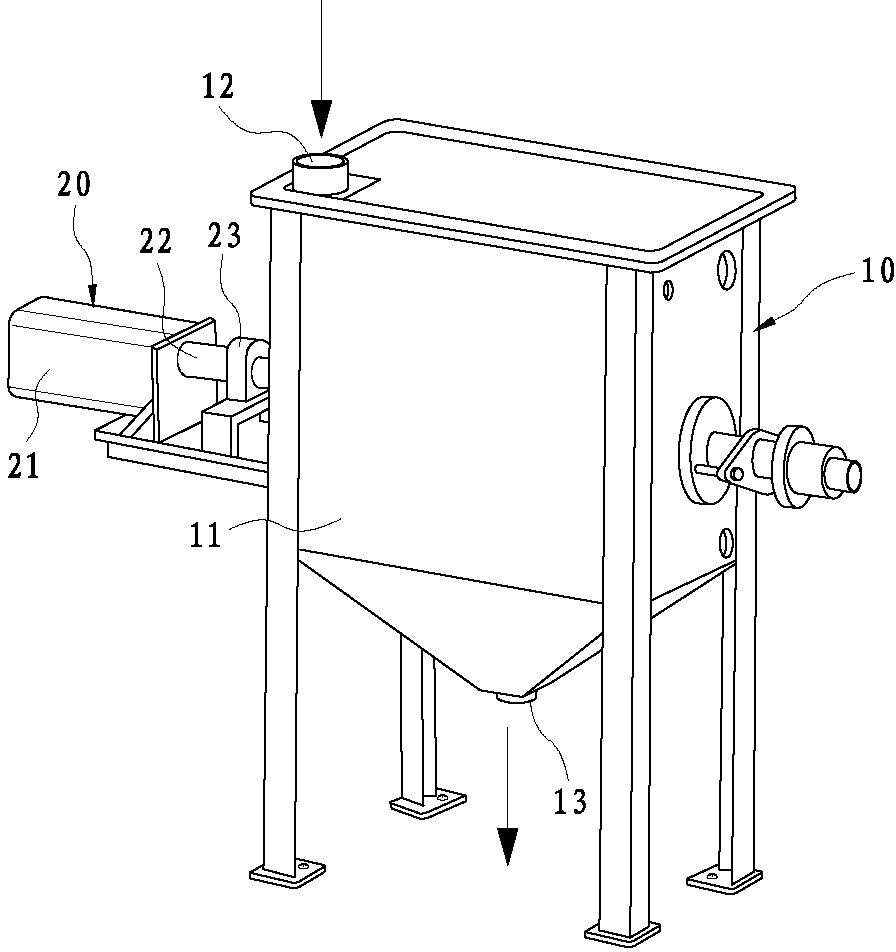

[0028] refer to figure 1 and figure 2 , an embodiment of the water treatment device that can scrape off the sludge on the surface of the filter membrane of the present invention includes a treatment tank 10, a driving unit 20, a water production pipe 30, a filter unit 40, a scraping unit 50 and a button Combined unit 60.

[0029] The treatment tank 10 has a hollow top and a funnel-shaped tank wall 11, a water inlet 12 positioned at the top of the tank wall 11, a discharge port 13 away from the water inlet 12, and a wall 11 formed by the tank wall 11. The inner chamber 14 is enclosed, and the feed water level in the inner chamber 14 is lower than the filtering unit 40 . In this embodiment, the discharge port 13 of the treatment tank 10 is located at the center bottom of the tank wall 11 to provide discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com