Extrusion palletizing urea-formaldehyde multi-nutrient element sustained-release fertilizer and preparation method

一种缓控释化肥、营养元素的技术,应用在施肥方法、植物学设备和方法、尿素复合肥等方向,能够解决限制包膜肥料推广和应用、养分单一、缓释周期长等问题,达到规模化生产前景广阔、制备工艺简单有效、节省人力和物力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

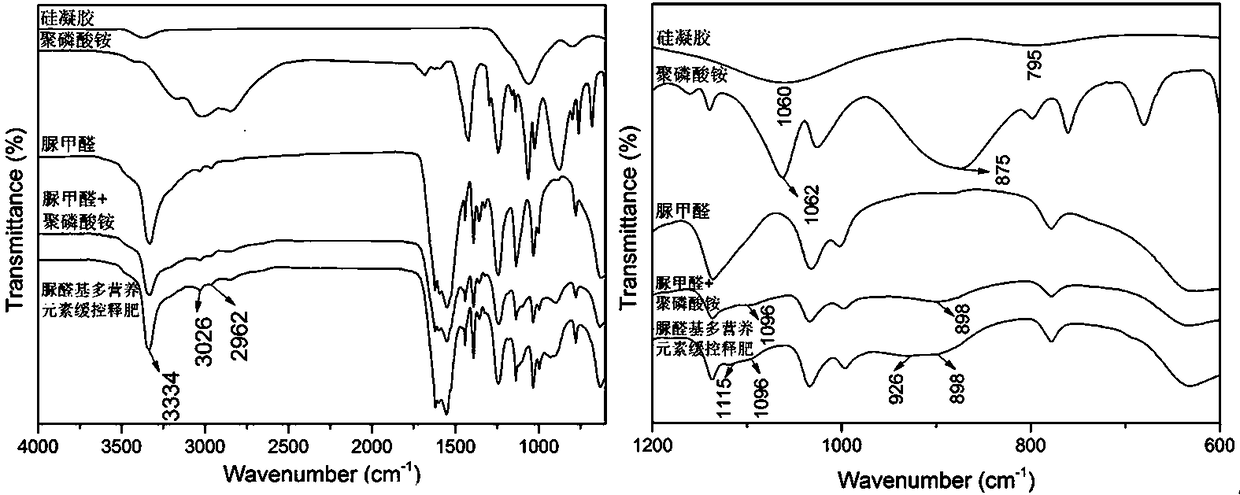

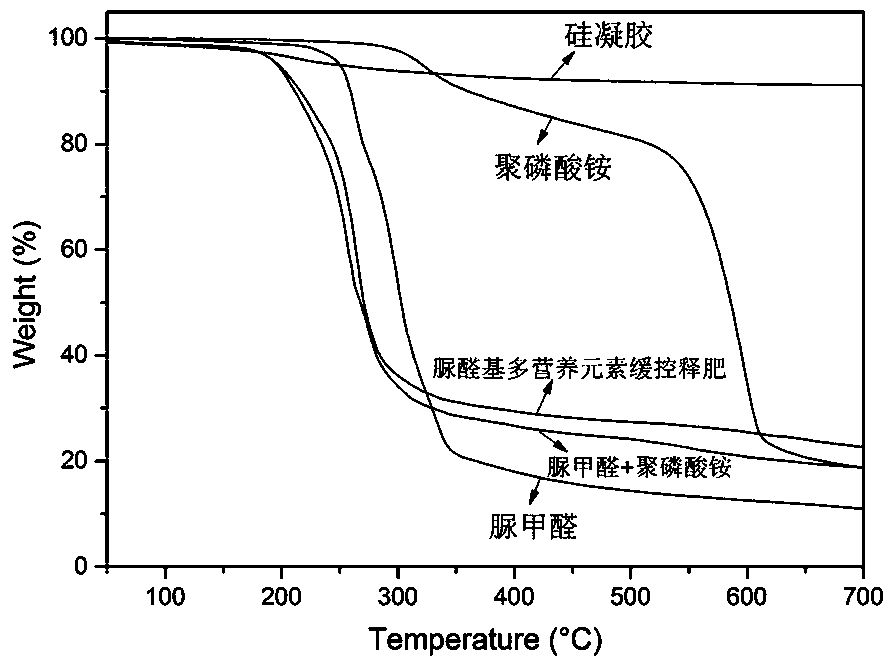

[0038] The urea-formaldehyde-based slow-controlled release fertilizer with multi-nutrient elements has a strong hydrogen bond network structure, can release nitrogen nutrients stably and continuously during the entire release period, and makes up for the problem of excessively long nutrient release period of existing urea-formaldehyde fertilizers. The present invention has no special requirements for the preparation method of the aforementioned urea-formaldehyde-based multi-nutrient element slow-controlled release fertilizer, as long as the urea-formaldehyde-based multi-nutrient element slow-controlled release fertilizer with the aforementioned structure can be prepared. According to a preferred embodiment of the present invention, the present invention further provides a method for preparing an extruded and granulated urea-formaldehyde-based multi-nutrient slow-release fertilizer, comprising the following steps:

[0039] (1) Add the calculated amount of formaldehyde and urea r...

Embodiment 1

[0056] A method for preparing an extruded granulated urea-formaldehyde-based multi-nutrient slow-release fertilizer, comprising the following steps:

[0057] (1) Add formaldehyde and urea at a molar ratio of 1:1 to the reactor respectively, adjust the pH of the system to 8, and react at 20° C. for 2 hours to obtain a methylolurea solution. Then add 9g ammonium dihydrogen phosphate and 7g potassium silicate to the reactor successively, and continue the reaction until the system is viscous;

[0058] (2) After solidifying the obtained viscous product at room temperature for 24 hours, extrude the strip with an extruder, then place the strip at 120°C for 1 hour and then cut it into pellets to obtain cylindrical urea-formaldehyde Multi-nutrient slow-release fertilizer.

[0059] The nitrogen content of the urea-formaldehyde-based multi-nutrient element slow-controlled release chemical fertilizer of gained extruding granulation is 21.84%, with P 2 o 5 The phosphorus content of the ...

Embodiment 2

[0061] A preparation method of extruded granulated urea-formaldehyde-based multi-nutrient slow-controlled release fertilizer, comprising the following steps:

[0062] (1) Add formaldehyde and urea with a molar ratio of 1:1.2 to the reactor respectively, adjust the system pH=9, react at 50° C. for 2 hours, and obtain a methylol urea solution. Add 9g of ammonium dihydrogen phosphate and 28g of potassium silicate to the reactor successively afterwards, and continue the reaction until the system is viscous;

[0063] (2) After solidifying the obtained viscous product at room temperature for 0.5 hours, extrude the strips with an extruder, then place the strips at 160°C for 0.5 hours and then cut into pellets to obtain short-section cylinders Urea-formaldehyde-based multi-nutrient slow-release fertilizer.

[0064] The nitrogen content of the urea-formaldehyde-based multi-nutrient slow-release fertilizer of gained extrusion granulation is 15.32%, expressed as P 2 o 5The calculated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com