Water swelling type water-blocking belt for optical cables and cables and preparation method thereof

A water-swelling and water-blocking tape technology, applied in insulated cables, chemical instruments and methods, cables, etc., can solve the problems of poor water-absorbing and water-blocking performance, cumbersome structure, and many layers, and achieve strong water-absorbing and water-blocking performance, preventing The effect of mouse bite and fewer layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037]A method for preparing the water-absorbing swelling type water-blocking tape for the above-mentioned optical cable, the preparation method comprising the following steps: firstly spray the high water-absorbing swelling material evenly on the base layer 1 to form the water-absorbing layer 2, and then spray the water-absorbing layer on the protective layer 3 The inner wall is sprayed with a mist-like liquid with adhesive properties, and then the protective layer 3 is wrapped on the outside of the water-absorbing layer 2 by hot pressing, and the side of the protective layer 3 that is sprayed with the mist-like liquid with adhesive properties and the water-absorbing layer The two phases are in contact, and the temperature of the hot pressing is room temperature -80°C. After the hot pressing is completed, the water-absorbing expansion type water blocking tape can be obtained.

[0038] A method for preparing the above-mentioned water-absorbing swelling type water-blocking tape ...

Embodiment 1

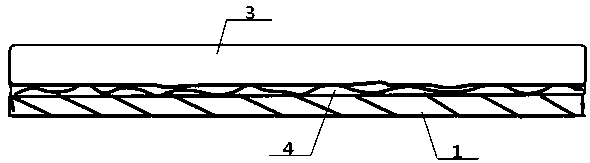

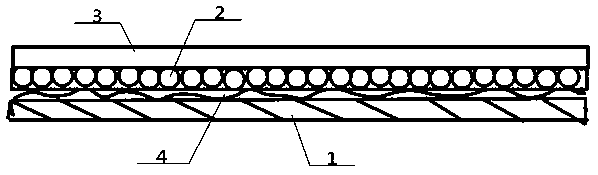

[0044] see figure 1 and figure 2 , a water-absorbing expansion type water-blocking tape for an optical cable, comprising a base layer 1, a water-absorbing layer 2 and a protective layer 3, wherein the inner wall of the base layer 1 is in contact with the outside of the optical cable or cable, and the bottom surface of the water-absorbing layer 2 is in contact with the base layer The outer walls of 1 are connected, and the parts of the water-absorbing layer 2 outside the junction of the water-absorbing layer 2 and the base layer 1 are covered with a protective layer 3, and the bottom of the protective layer 3 covers the junction of the water-absorbing layer 2 and the base layer 1 Above; the water-absorbing layer 2 includes a high water-absorbing swelling material, and the protective layer 3 is a film that can be dissolved after absorbing water. The protective layer 3 is any one of polyvinyl alcohol film, polyester film and polyurethane film. The high water-absorbing swelling...

Embodiment 2

[0047] Basic content is the same as embodiment 1, the difference is:

[0048] The bottom surface of the water-absorbing layer 2 is connected to the outer wall of the base layer 1 through the adhesive layer 4, and the high water-swelling material is in powder form, and the high water-swelling material is sprayed on the adhesive layer 4 by electrostatic flocking. The adhesive layer 4 is formed by smearing an adhesive, and the adhesive is a mixture of an adhesive material and an organic solvent, and the adhesive material is epoxy, polyurethane, polyvinyl butyral, poly Any one or any mixture of vinyl alcohol and polyvinyl pyrrolidone, the mass percent concentration of the binder is 5%. A preferred organic solvent is ethanol.

[0049] A method for preparing the above-mentioned water-absorbing swelling water-blocking tape for optical cables, the preparation method comprising the following steps: firstly mixing the bonding material with an organic solvent to obtain a binder, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com