Preparation method of lithium ion battery positive plate and lithium battery manufactured thereby

A technology for lithium ion batteries and positive electrode sheets, which is applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of poor flexibility of the electrode sheets, uneven coating, and temperature rise, and achieve the effect of reducing easy fragmentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A preparation method of lithium ion battery positive plate, it comprises the following steps:

[0032] Step 1, using nitrogen methylpyrrolidone NMP or amides as solvent, adding dry powder mixed with PVDF, PEO, PVP or mixed with PVDF, PEO, PEG, wherein the weight ratio of PVDF:PEO:PVP or PVDF:PEO:PEG 18.5:1:0.5 to 16:3.5:0.5; formulated as 4-8 wt% glue. Among them, the amides can be dimethylformamide, diethylacetamide or dimethylacetamide and the like. With NMP or amides as solvent, PVDF, PEO, PVP, PEG can be dissolved.

[0033] Step 2, mix the positive electrode active material and the conductive agent for 30 to 60 minutes, then add 1 / 3 of the glue and stir for 20 to 40 minutes, then add 1 / 3 of the glue and stir for 20 to 30 minutes, and finally put the remaining 1 / 3 of the glue solution was added and stirred for 10 to 20 minutes to prepare a positive electrode slurry with a solid content of 78 to 85%. Add the glue solution into the mixture of the positive electrode ...

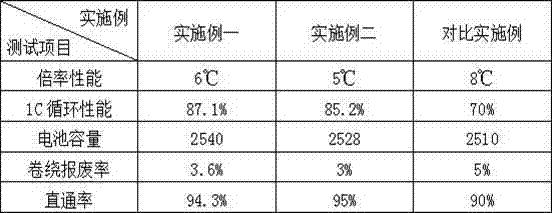

Embodiment 1

[0039] Embodiment one, a kind of preparation method of lithium-ion battery, comprises the following steps:

[0040] S1. Add dry powder of PVDF, PEO, PVP (or PEG) with nitrogen methylpyrrolidone (NMP) or amides (such as: dimethylformamide, diethylacetamide, dimethylacetamide) solvent, Among them, the ratio of PVDF:PEO:PVP is 18.5:1:0.5; it is formulated into 4-8wt% glue.

[0041] S2. Mix the positive electrode active material and the conductive agent for 30-60 minutes, add 1 / 3 of the glue and stir for 20-40 minutes, add 1 / 3 of the glue and stir for 20-30 minutes, add the remaining 1 / 3 of the glue and stir for 10-20 minutes, Prepare a slurry with a solid content of 78-85%.

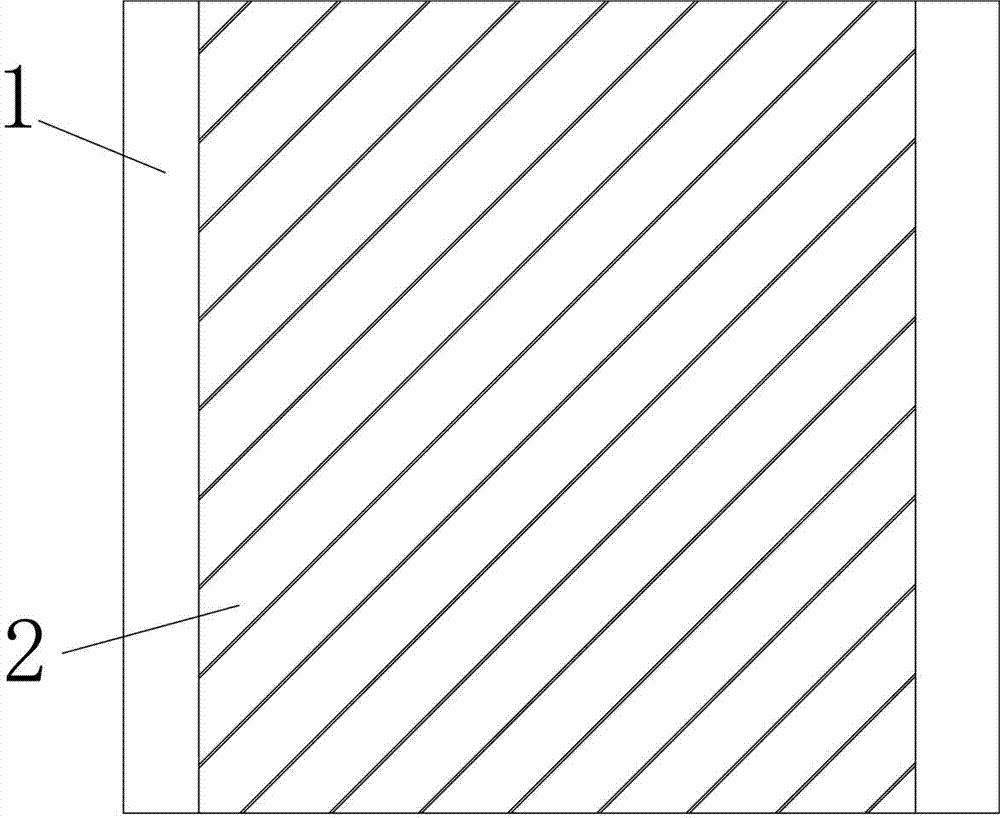

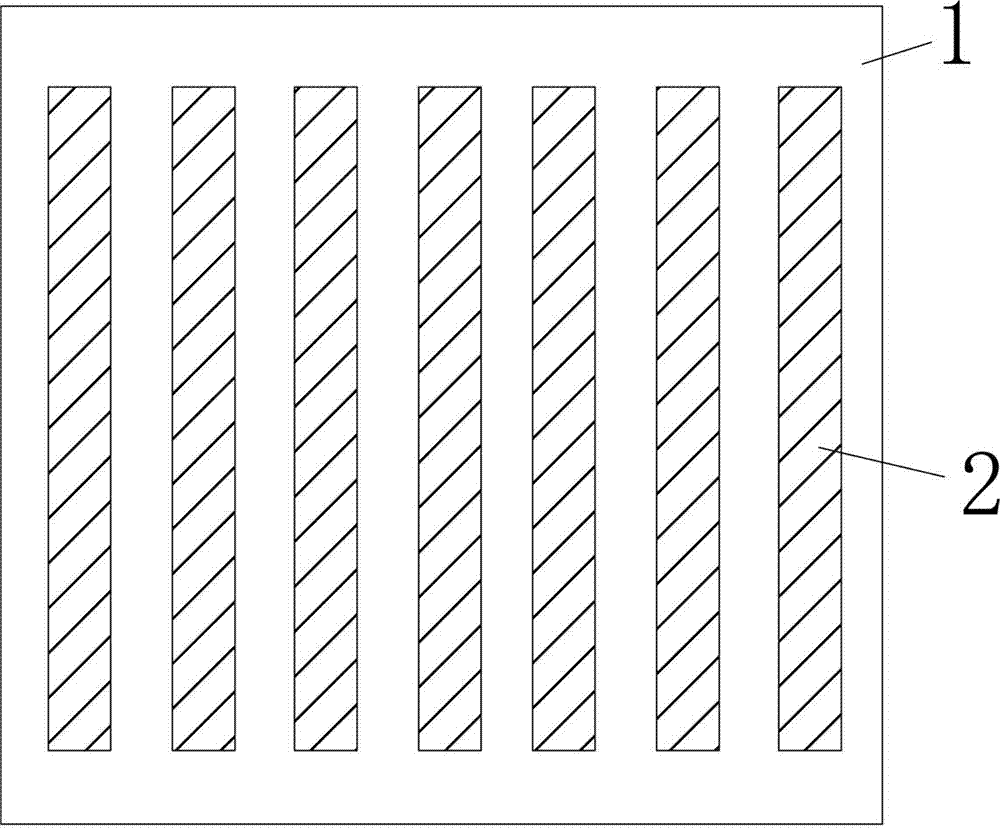

[0042] S3. Using the silk screen printing process, some of the mesh holes of the screen template will leak the positive and negative electrode slurry onto the surface of the aluminum foil and copper foil current collector respectively, and the rest of the mesh holes will be blocked and cannot pass through t...

Embodiment 2

[0044] Embodiment two, a kind of preparation method of lithium ion battery, comprises the following steps:

[0045]S1. Add dry powder of PVDF, PEO, PVP (or PEG) with nitrogen methylpyrrolidone (NMP) or amides (such as: dimethylformamide, diethylacetamide, dimethylacetamide) solvent, Among them, the ratio of PVDF:PEO:PVP is 16:3.5:0.5; it is formulated into 4-8wt% glue.

[0046] S2. Mix the positive electrode active material and the conductive agent for 30-60 minutes, add 1 / 3 of the glue and stir for 20-40 minutes, add 1 / 3 of the glue and stir for 20-30 minutes, add the remaining 1 / 3 of the glue and stir for 10-20 minutes, Prepare a slurry with a solid content of 78-85%.

[0047] S3. Using the silk screen printing process, some of the mesh holes of the screen template will leak the positive and negative electrode slurry onto the surface of the aluminum foil and copper foil current collector respectively, and the rest of the mesh holes will be blocked and cannot pass through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com