A XLPE insulated DC cable for urban light rail subway

A cross-linked polyethylene, DC cable technology, applied in the direction of insulated cables, insulators, insulated conductors, etc., can solve the problem that the cable cannot fully meet the needs of use, and achieves slow down the rate of auto-oxidation reaction, not easy to wear, and good electrical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

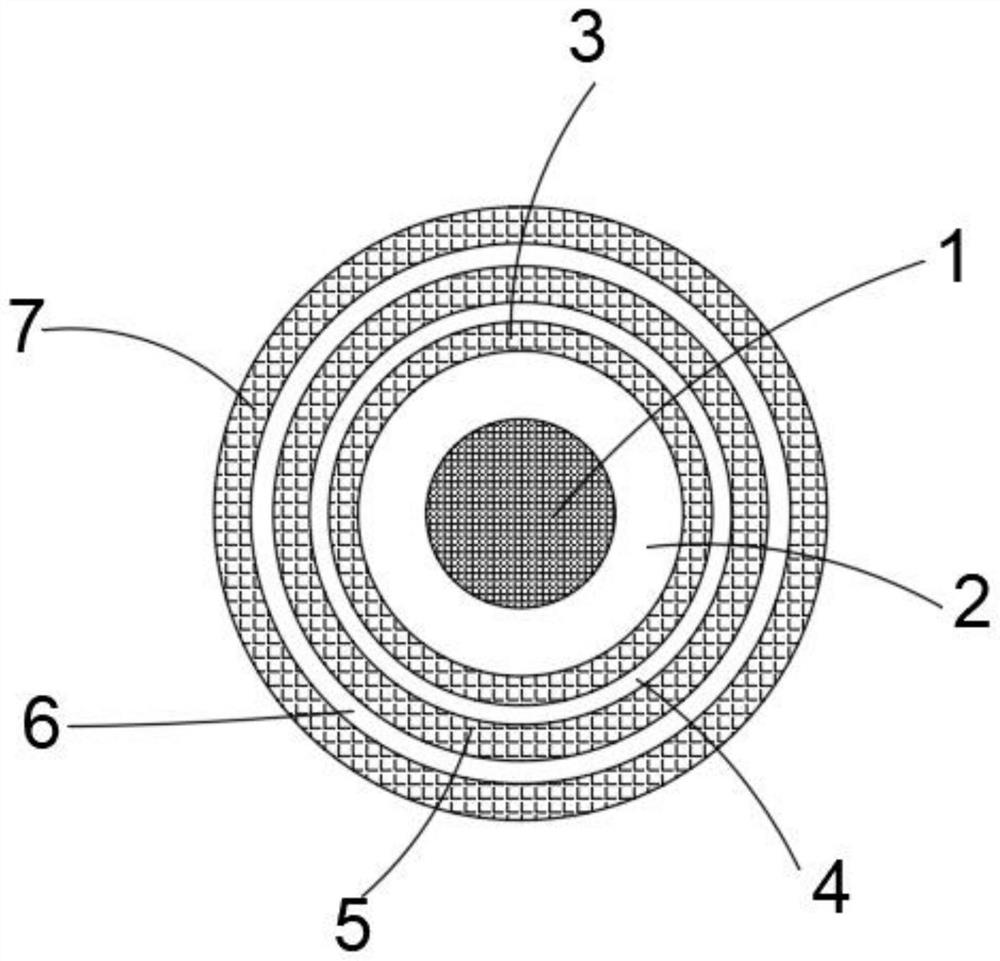

[0036] see figure 1 As shown in the figure, a cross-linked polyethylene insulated DC cable for urban light rail subway, including copper conductor 1, cross-linked polyethylene insulating layer 2, intumescent water blocking tape 3, aluminum-plastic bonded comprehensive protective layer 4, low smoke halogen free Flame retardant inner protective layer 5, anti-mouse ant layer 6 and outer sheath 7;

[0037] The cross-linked polyethylene insulating layer 2 covers the copper conductor 1, the intumescent water-blocking tape 3 covers the cross-linked polyethylene insulating layer 2, and the aluminum-plastic bonding comprehensive protective layer 4 is extruded. The intumescent water-blocking tape 3 is covered, the low-smoke halogen-free flame retardant inner protective layer 5 is wrapped with an aluminum-plastic bonding comprehensive protective layer 4, and the anti-mouse and ant layer 6 is wrapped Covering the low-smoke halogen-free flame-retardant inner protective layer 5, and the ou...

Embodiment 2

[0057] see figure 1 As shown in the figure, a cross-linked polyethylene insulated DC cable for urban light rail subway, including copper conductor 1, cross-linked polyethylene insulating layer 2, intumescent water blocking tape 3, aluminum-plastic bonding comprehensive protective layer 4, low smoke halogen free Flame retardant inner protective layer 5, anti-mouse ant layer 6 and outer sheath 7;

[0058] The cross-linked polyethylene insulating layer 2 covers the copper conductor 1, the intumescent water-blocking tape 3 covers the cross-linked polyethylene insulating layer 2, and the aluminum-plastic bonding comprehensive protective layer 4 is extruded. The intumescent water-blocking tape 3 is covered, the low-smoke halogen-free flame retardant inner protective layer 5 is wrapped with an aluminum-plastic bonding comprehensive protective layer 4, and the anti-mouse and ant layer 6 is wrapped Covering the low-smoke halogen-free flame-retardant inner protective layer 5, and the o...

Embodiment 3

[0078] see figure 1 As shown in the figure, a cross-linked polyethylene insulated DC cable for urban light rail subway, including copper conductor 1, cross-linked polyethylene insulating layer 2, intumescent water blocking tape 3, aluminum-plastic bonded comprehensive protective layer 4, low smoke halogen free Flame retardant inner protective layer 5, anti-mouse ant layer 6 and outer sheath 7;

[0079] The cross-linked polyethylene insulating layer 2 covers the copper conductor 1, the intumescent water-blocking tape 3 covers the cross-linked polyethylene insulating layer 2, and the aluminum-plastic bonding comprehensive protective layer 4 is extruded. The intumescent water-blocking tape 3 is covered, the low-smoke halogen-free flame retardant inner protective layer 5 is wrapped with an aluminum-plastic bonding comprehensive protective layer 4, and the anti-mouse and ant layer 6 is wrapped Covering the low-smoke halogen-free flame-retardant inner protective layer 5, and the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com