Ash coating additive, preparation method and ash coating cigarette paper

A technology of cigarette paper and additives, applied in papermaking, paper, textiles and papermaking, etc., can solve problems such as poor ash-packing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

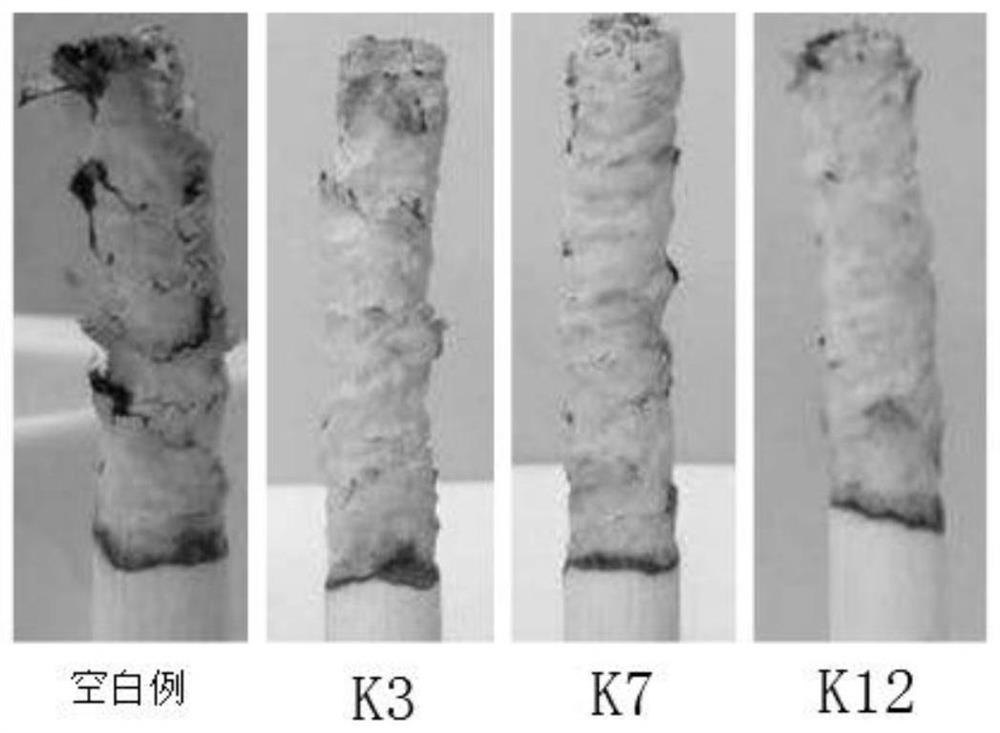

Embodiment 1

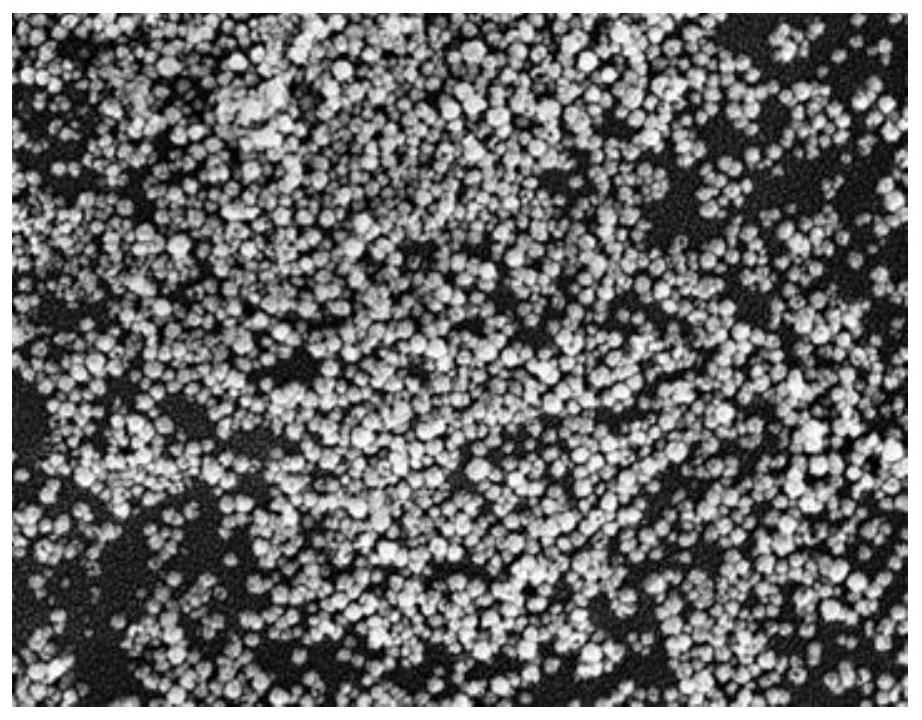

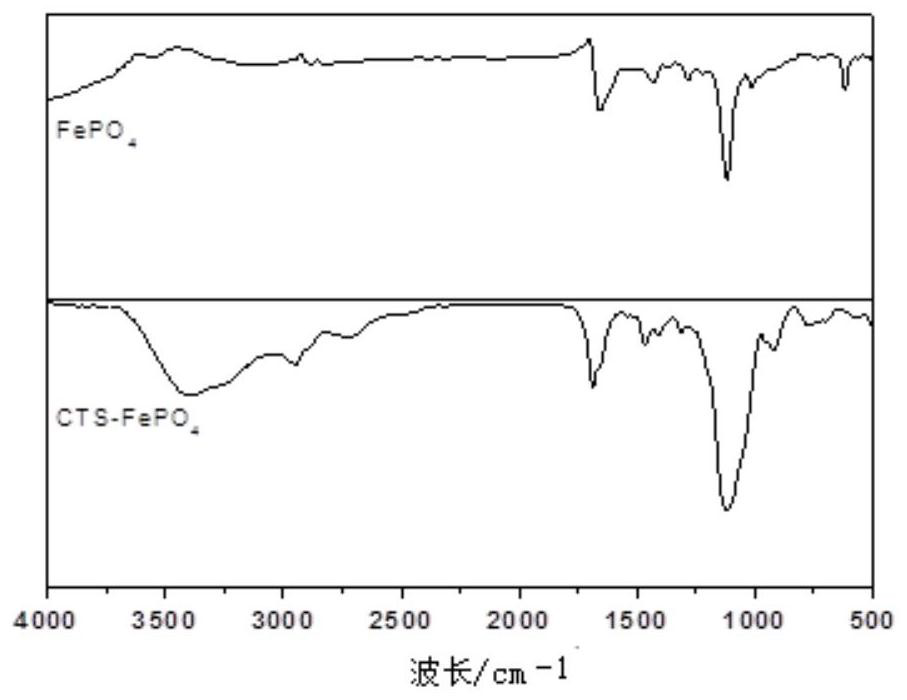

[0033] The preparation method of dust-coating auxiliary agent, preparation 1000ml mass percentage concentration is the FeSO of 150ppm 4 Aqueous solution; Weigh FeSO 4 Add 3% urea in aqueous solution and 0.25% stabilizer cetyltrimethylammonium bromide to FeSO 4 In the aqueous solution, stir to make the urea and the stabilizer dissolve completely, and obtain the mixed solution A1; add the mass percentage concentration of 100ppm H 3 PO 4 , and mixed evenly to obtain the mixed solution B1; the mixed solution B1 was placed in a microwave reactor and reacted for 15 minutes at a temperature of 75°C. After the reaction, the FePO was collected by centrifugation 4 nanoparticles, and washed with pure water to remove impurities; the FePO 4 Nanoparticles are dispersed in pure water, chitosan is added under ultrasound, the molecular weight of chitosan used is -10000Da, chitosan and FePO 4 The mass ratio is 1, the reaction temperature is 20°C, and the reaction time is 0.5h; after the rea...

Embodiment 2

[0035] The preparation method of dust-coating auxiliary agent, preparation 1000ml mass percent concentration is the FeSO of 300ppm 4 Aqueous solution; Weigh FeSO 4 Add 3% urea in aqueous solution and 0.25% stabilizer cetyltrimethylammonium bromide to FeSO 4 In the aqueous solution, stir to make the urea and the stabilizing agent dissolve completely, obtain the mixed solution A2; add the mass percent concentration in the mixed solution A2 and be 200ppm H 3 PO 4 , and mixed evenly to obtain the mixed solution B2; the mixed solution B2 was placed in a microwave reactor and reacted at a temperature of 95°C for 15 minutes. After the reaction, the FePO was collected by centrifugation 4 nanoparticles, and washed with pure water to remove impurities; the FePO 4 Nanoparticles are dispersed in pure water, chitosan is added under ultrasound, the molecular weight of chitosan used is ˉ10000Da, chitosan and FePO 4 The mass ratio is 3, the reaction temperature is 40°C, and the reaction t...

Embodiment 3

[0037] The preparation method of dust-coating auxiliary agent, the preparation 1000ml mass percentage concentration is the FeSO of 200ppm 4 Aqueous solution; Weigh FeSO 4 Add 3% urea in aqueous solution and 0.25% stabilizer cetyltrimethylammonium bromide to FeSO 4 In the aqueous solution, stir to make the urea and the stabilizer dissolve completely, and obtain the mixed solution A3; add the mass percent concentration of 100ppm H 3 PO 4, and mixed evenly to obtain the mixed solution B3; the mixed solution B3 was placed in a microwave reactor, and reacted at a temperature of 90°C for 15 minutes. After the reaction, the FePO was collected by centrifugation 4 nanoparticles, and washed with pure water to remove impurities; the FePO 4 Nanoparticles are dispersed in pure water, chitosan is added under ultrasound, the molecular weight of chitosan used is ˉ10000Da, chitosan and FePO 4 The mass ratio is 2, the reaction temperature is 20°C, and the reaction time is 0.5h; after the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com