Novel B type large-pore volume silica gel and manufacture method thereof

A production method and technology of large pore volume, applied in the direction of silicon oxide, silicon dioxide, etc., to achieve high porosity, change the pore volume and specific surface area, and improve the application field and use method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

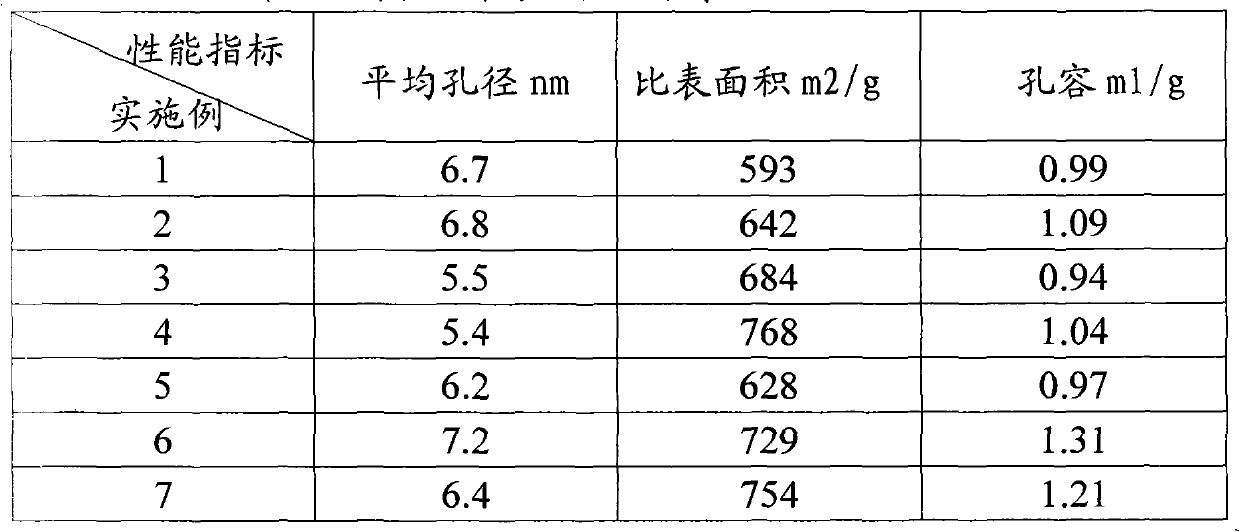

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific embodiment:

[0017] A novel B-type macroporous silica gel and a manufacturing method thereof, comprising the following steps:

[0018] A. According to the transmission silica gel process, the sodium silicate solution and the dilute inorganic acid are used to generate orthosilicic acid in the vortex mixing reactor, and then solidify after standing, and then granulate for the second time;

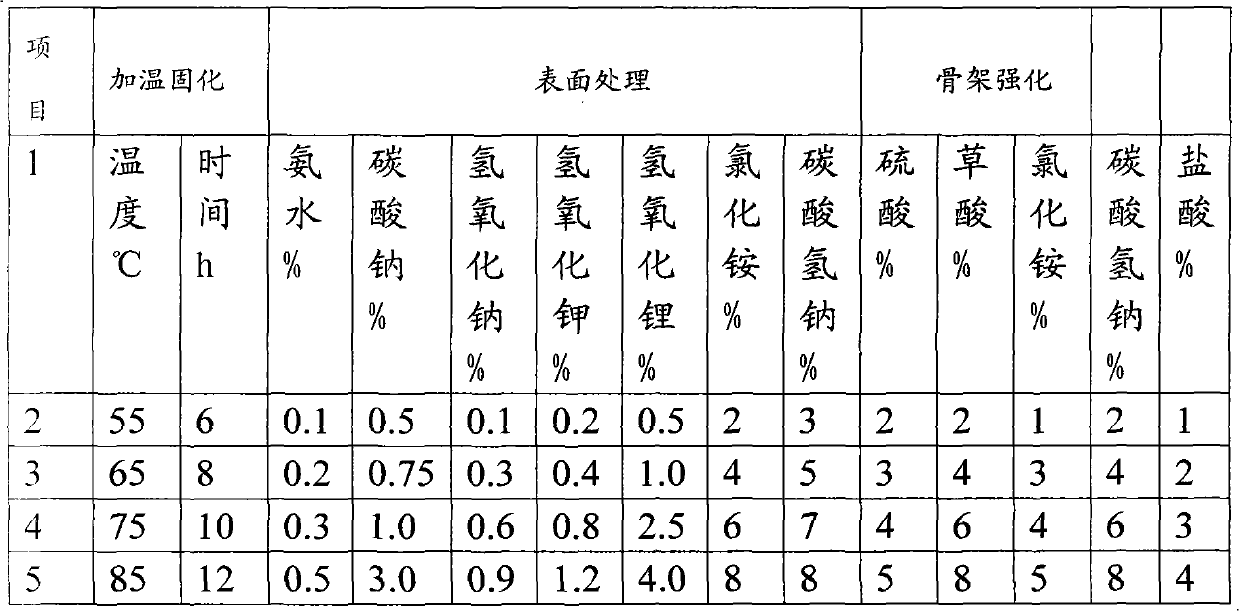

[0019] B. Heating and curing, place the silica gel in an environment with a temperature of 40-90°C for 8-24 hours.

[0020] C. Surface treatment, the washed silica gel is then subjected to surface treatment with inorganic salts and inorganic alkalis. Modification of silanol groups on the inner surface of silica gel pores, the choice of alkali: sodium hydroxide, potassium hydroxide, lithium hydroxide, the choice of inorganic salts: ammonium chloride, sodium chloride, sodium carbonate, sodium bicarbonate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com