Patents

Literature

40results about How to "Meet the use standard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

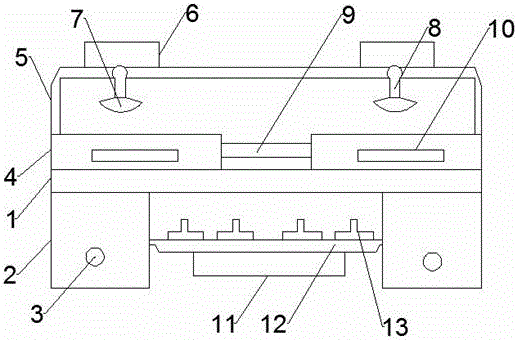

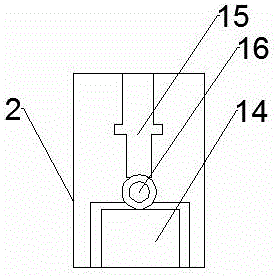

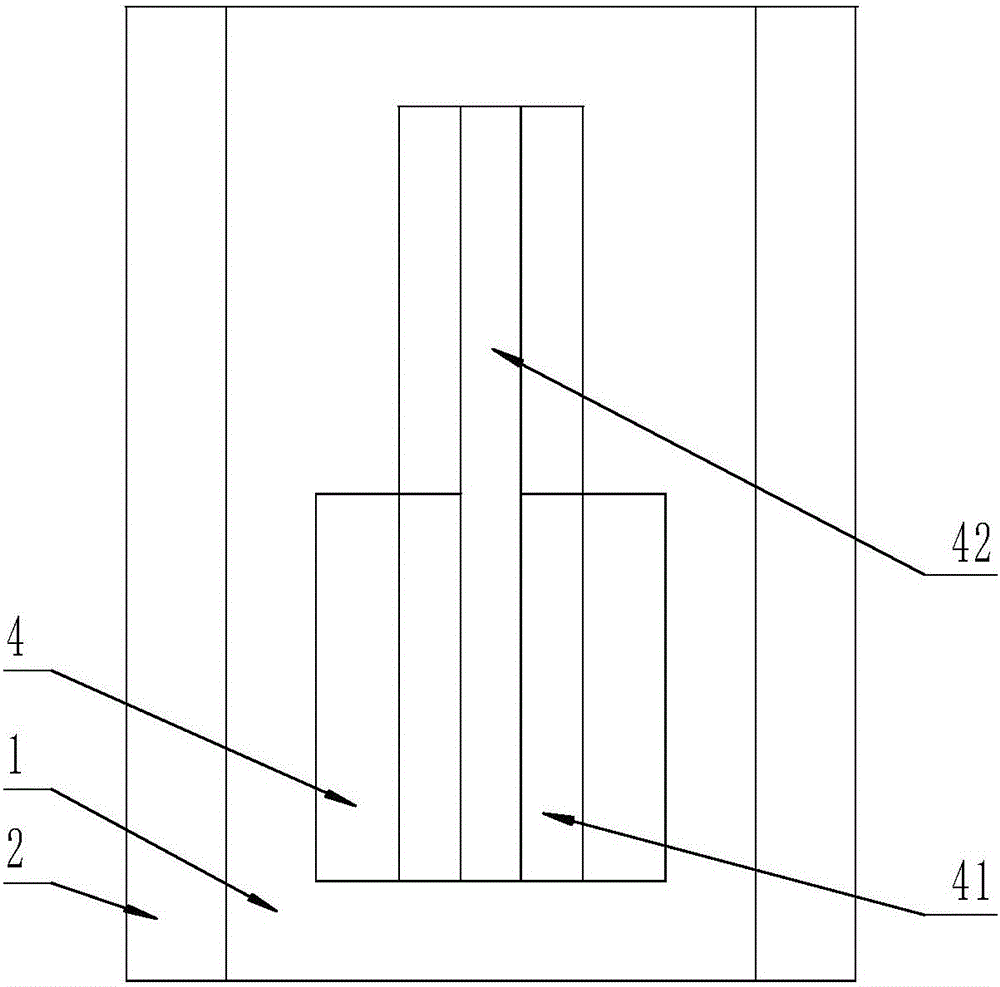

Improved engine oil filter

ActiveCN105065081AMeet the use standardLubricant mounting/connectionPressure lubricationOil canFilter element

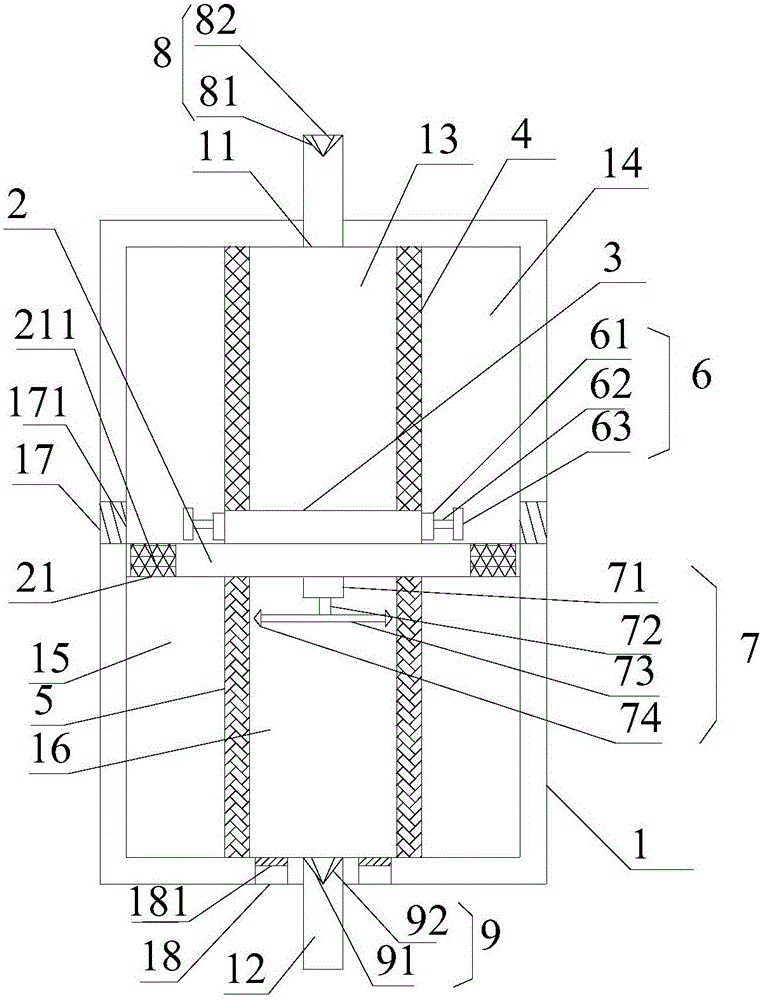

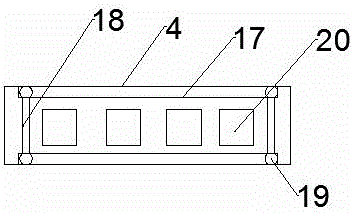

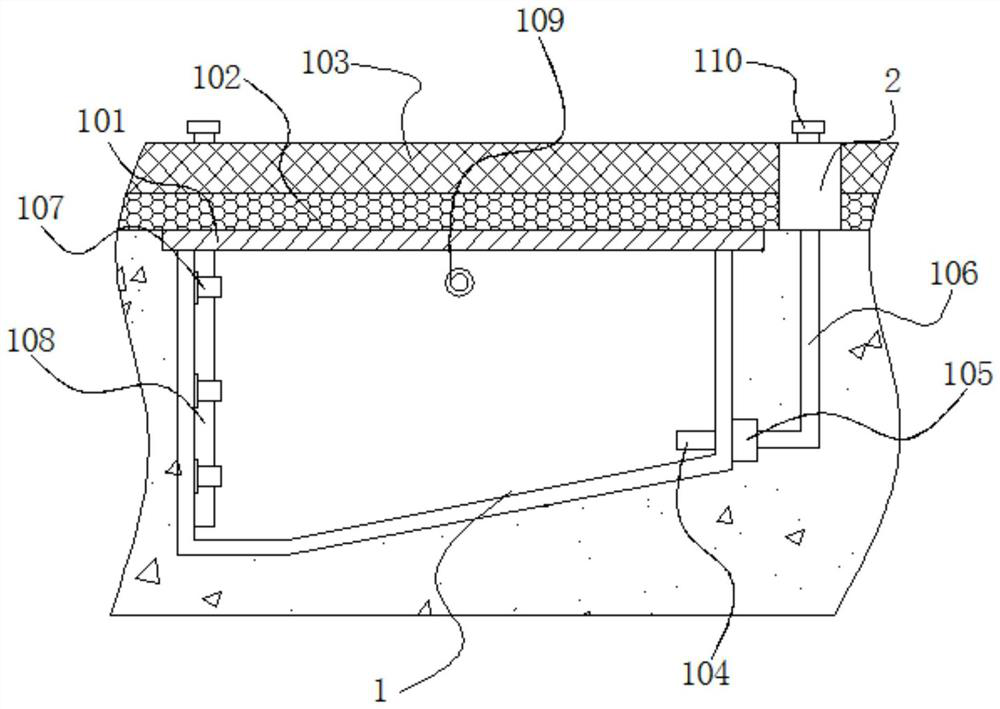

The invention provides an improved engine oil filter. The improved engine oil filter comprises a shell and a controller. A partition plate is arranged in the shell, and the inside of the shell is divided by the partition plate into a first chamber and a second chamber. Two through holes are symmetrically formed in the partition plate, and filter nets are arranged at the through holes respectively. First detection devices for detecting the thickness of filter residues on the filter nets are arranged on the filter nets respectively and connected with the controller. A base is arranged on one side, close to the first chamber, of the partition plate, and first cleaning devices are arranged at the portions, close to the through holes, of the base respectively. The first chamber is internally provided with a first filter element, and the inside of the first chamber is divided by the first filter element into a first filter cavity and a second filter cavity. The second chamber is internally provided with a second filter element, and the inside of the second chamber is divided by the second filter element into a third filter cavity and a fourth filter cavity. A second detection device for detecting the thickness of filter residues on the second filter element is arranged on the second filter element and connected with the controller. The fourth filter cavity is internally provided with a second cleaning device. By means of the improved engine oil filter, impurities in engine oil can be filtered out, the using standard of the engine oil can be met, and the filter residues on the filter elements can be easily removed.

Owner:威海威硬工具股份有限公司

Technological process of thermochemistry dehydrating for ultra thick oil

InactiveCN1687321AReduce consumptionLess investmentHydrocarbon oil dewatering/demulsificationElectricityDemulsifier

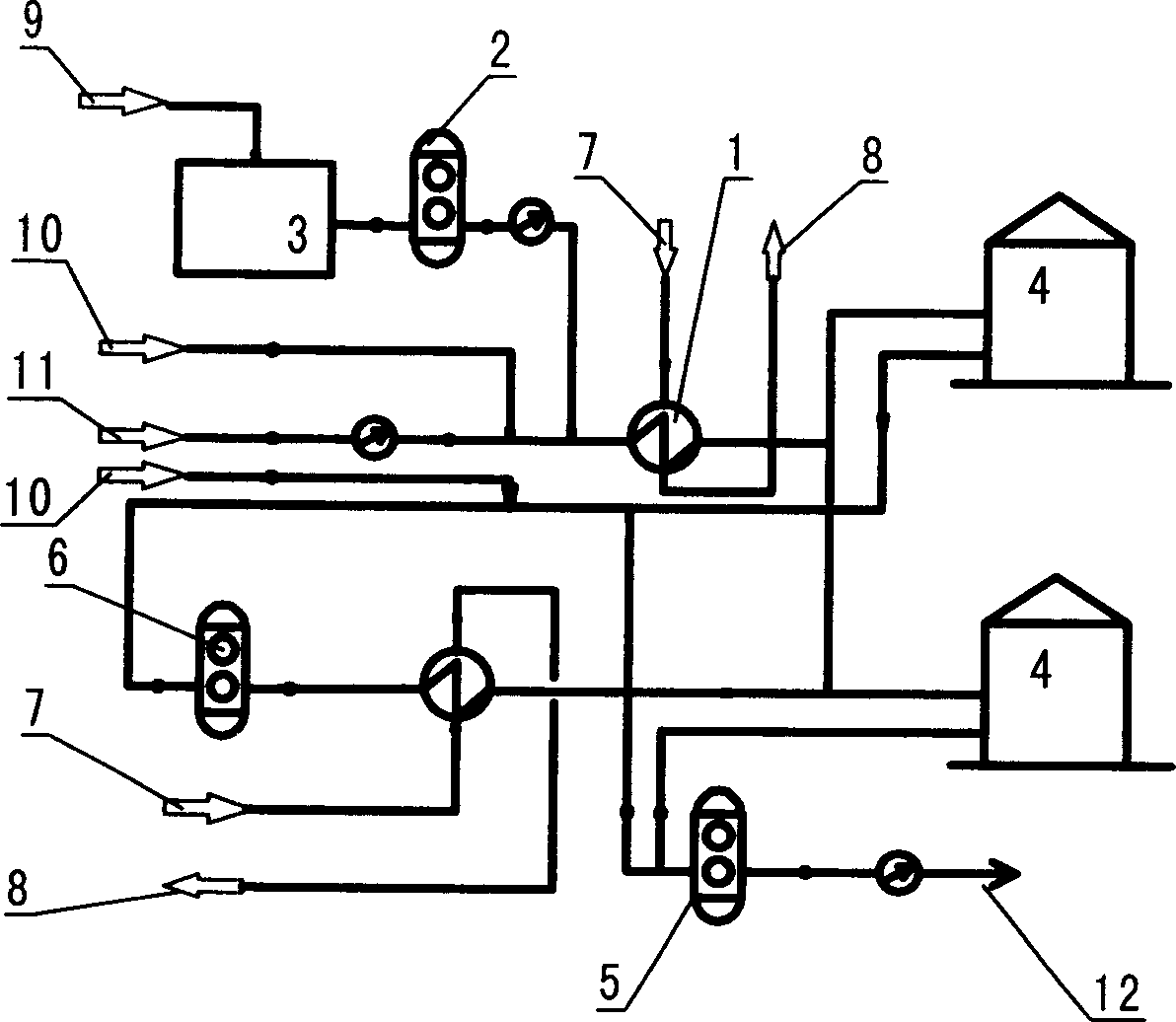

The present invention relates to a thermochemical dehydration process for ultrahenvy oil. Said invention is characterized by that it adopts thermochemical static settlement dehydration and indirect heat-supplying mode using heat transfer oil as thermal carrier, and adopts nodel tubular heat exchange equipment to implement thermochemical dehydration process of ultraheavy oil. In the course of dehydration LH-2 or RS-2 oil-soluble demulsifier with a certain concentration is added in the ultraheavy oil, and the water content of dehydrated and settled raw oil can be up to 3-5% standard.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

Preparation method of environment-friendly modified starch adhesive for cigarette

ActiveCN103242786AImprove liquidityHigh solid contentGraft polymer adhesivesBiotechnologyMethyl aldehyde

The invention discloses a preparation method of an environment-friendly modified starch adhesive for a cigarette, belonging to the technical field of an adhesive. The adhesive uses the starch as the main ingredient, is free of an organic solvent, is properly modified by adding a small amount of modifying agent, overcomes the inherent defects of the pure starch adhesive, such as low solid content, poor fluidity and poor storage stability, so that the product performance is improved greatly, and the product can meet production of a high-speed cigarette making machine, and is suitable for various cigarette adhesive joints, such as a cigarette holder and a connector. The auxiliary material used in the method is free from harmful substances such as methyl aldehyde and phthalic acid esters, under the premise of meeting the requirement on cigarette production, the sanitary and safe condition meets the sanitary standard of adhesive in China cigarette industry, and real environment-friendly property is realized.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

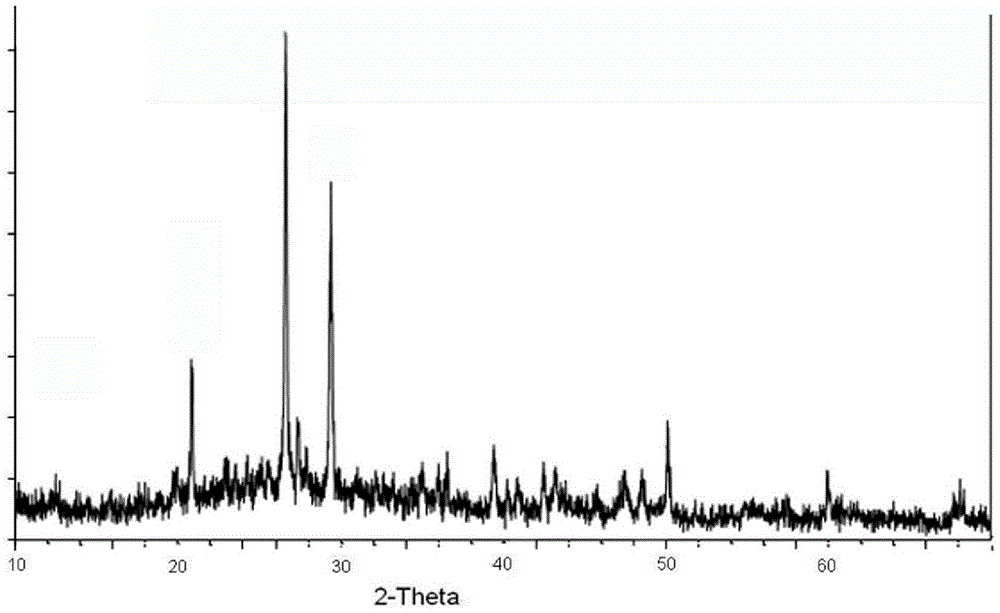

Stainless steel seamless tube for sodium-cooled fast reactor and preparation method of stainless steel seamless tube

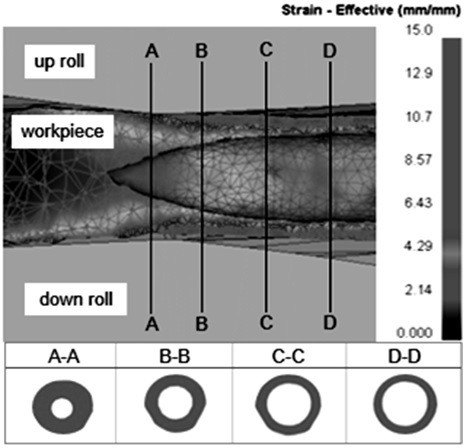

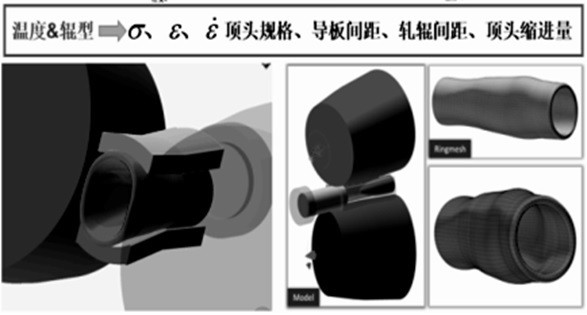

The invention discloses a stainless steel seamless tube for a sodium-cooled fast reactor. Microalloying component fine adjustment is carried out based on a 316H stainless steel base material, the stainless steel seamless tube comprises the following components in percentage by mass: 0.04-0.05% of C, less than or equal to 0.6% of Si, 1.00-2.00% of Mn, less than or equal to 0.030% of P, less than or equal to 0.003% of S, 17.0-18.0% of Cr, 11.5-12.5% of Ni, 2.50-2.70% of Mo, less than or equal to 0.10% of Cu, 0.05-0.07% of N, less than or equal to 0.0015% of B, less than or equal to 30 ppm of O, less than or equal to 5.0 ppm of H and the balance of Fe and impurities, and the ferrite content is controlled to be less than or equal to 1%. The stainless steel seamless tube for the sodium-cooled fast reactor is manufactured through a high-purity smelting process, microalloying component fine adjustment, a stainless steel casting process, a hot perforation treatment process and finished product cold machining. By means of the mode, the stainless steel seamless pipe for the sodium-cooled fast reactor and a preparation method can meet the use standard of nuclear safety high-temperature nano pipelines, and the stainless steel seamless pipe has obdurability, corrosion resistance and durability.

Owner:高虹

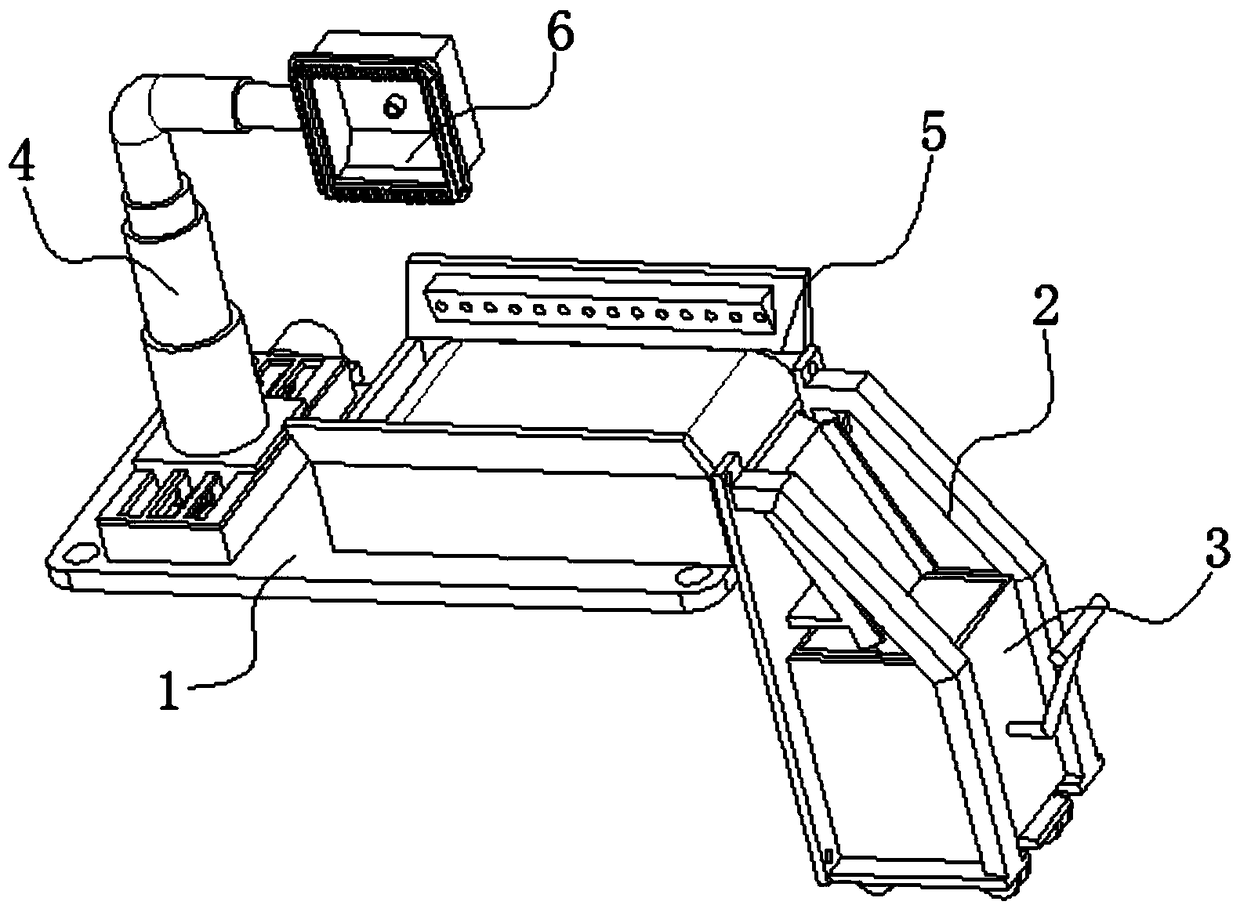

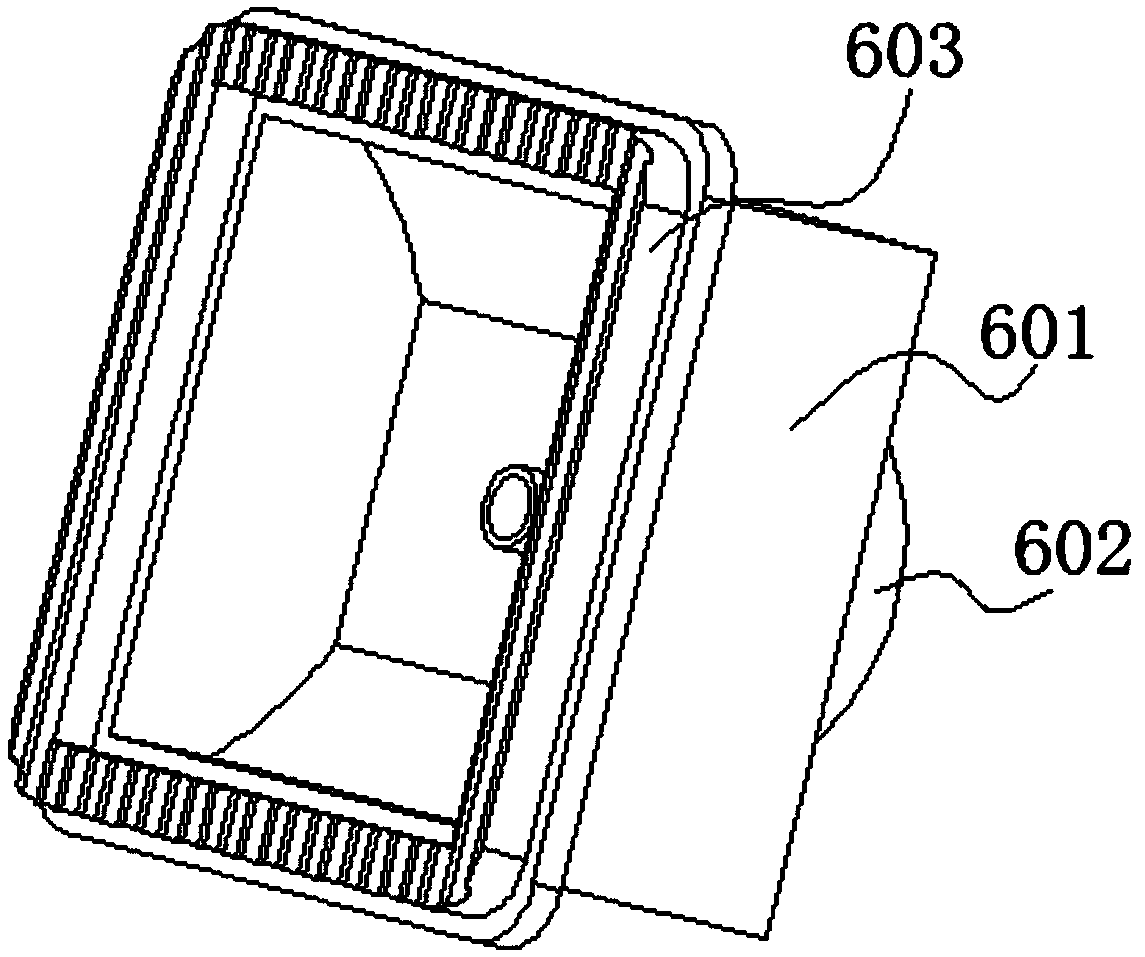

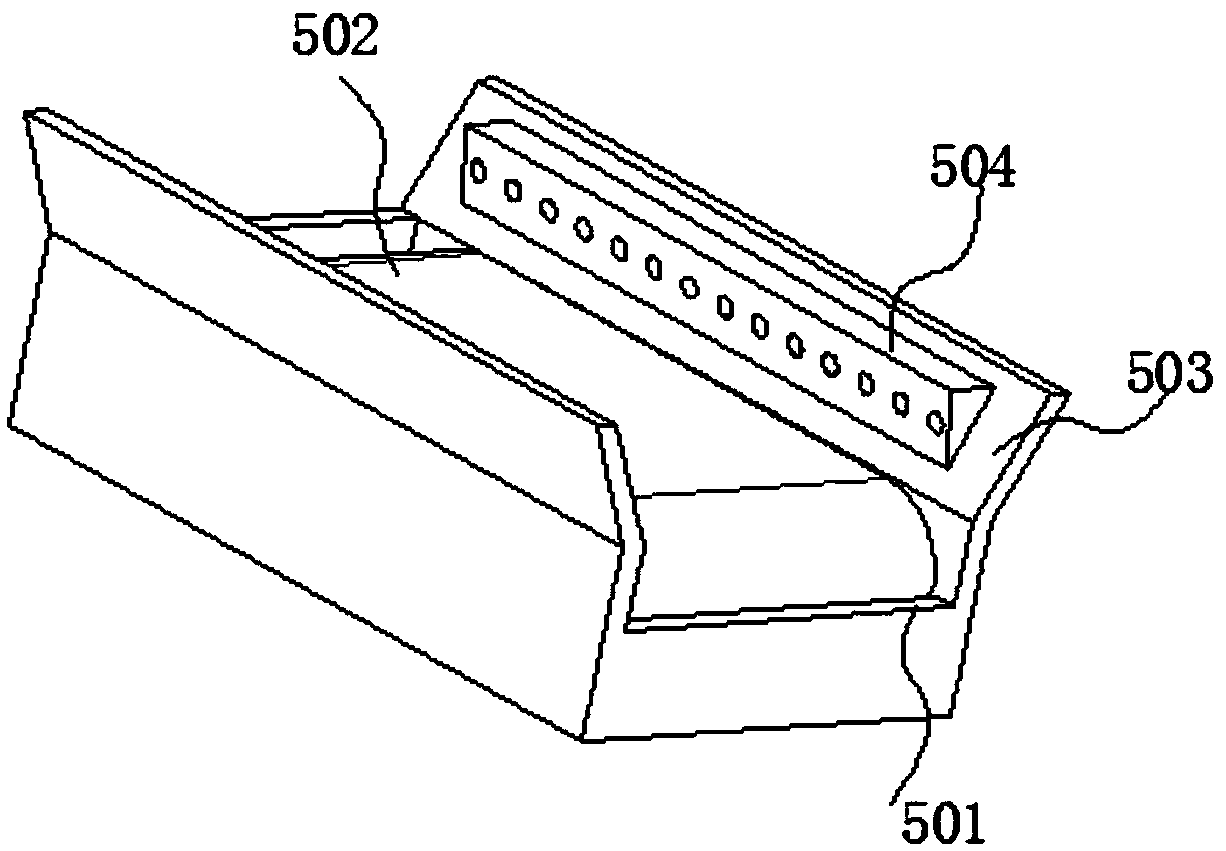

Taking-out device and taking-out method for plastic molds

The invention discloses a taking-out device and a taking-out method for plastic molds, and relates to the technical field of plastic products. The device comprises a base, a conveying frame and a receiving box; a transmission device and a conveying device are fixed on one surface of the base; a sucking device is fixed at an output end of the transmission device; the sucking device comprises a shell; an air pump is fixed on one surface of the shell; an air inlet of the air pump is positioned in the shell; a rubber ring is fixed on one surface of the shell; the conveying device comprises a conveying box; and a conveying belt module is arranged in the conveying box. Finished products can be totally taken out from molds through the sucking device to solve the problem of damage or deformation of the finished product caused by bonding in the molds; through air extraction by an air blower and air blowing to the finished products on the conveying belt by a flow separation box, the over temperature is cooled to solve the problem of deformation of the finished products caused by remaining of the over temperature of the finished products; and through arrangement of the conveying frame, the receiving box is conveniently disassembled and placed to solve the problem of inconvenience to collect the finished products.

Owner:WENZHOU POLYTECHNIC

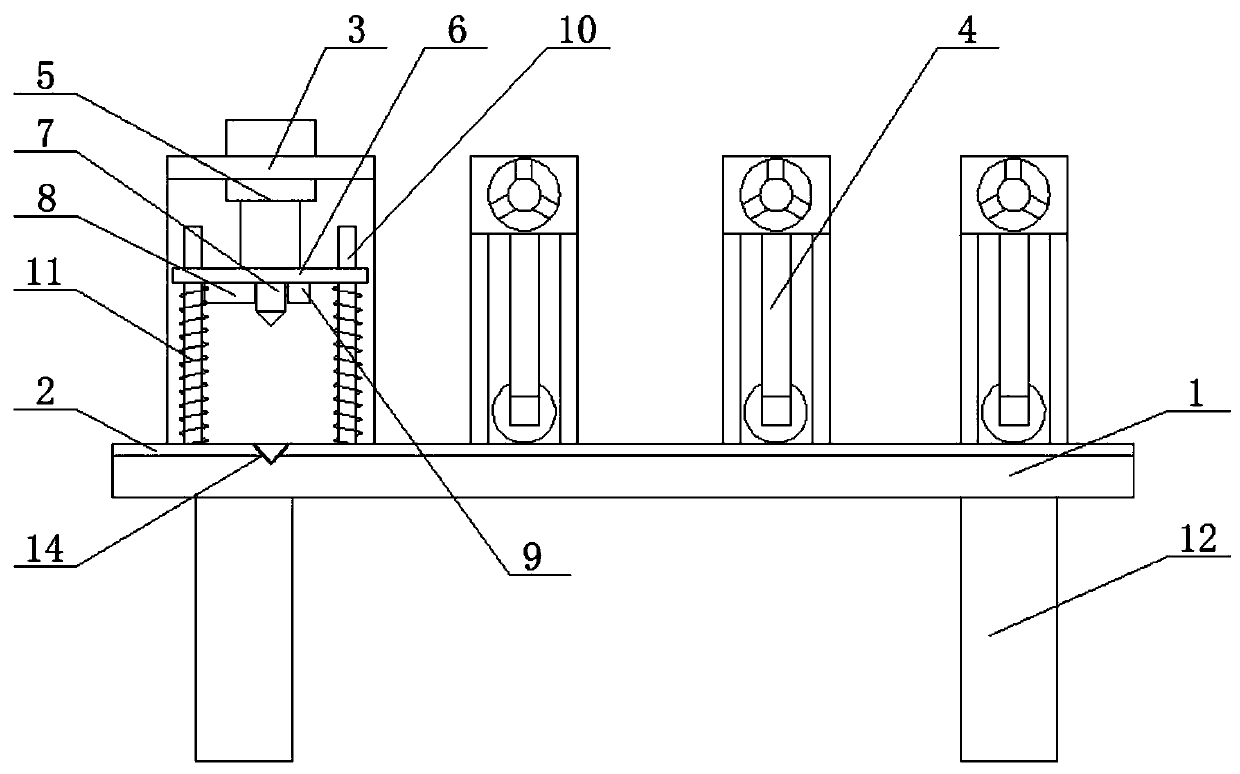

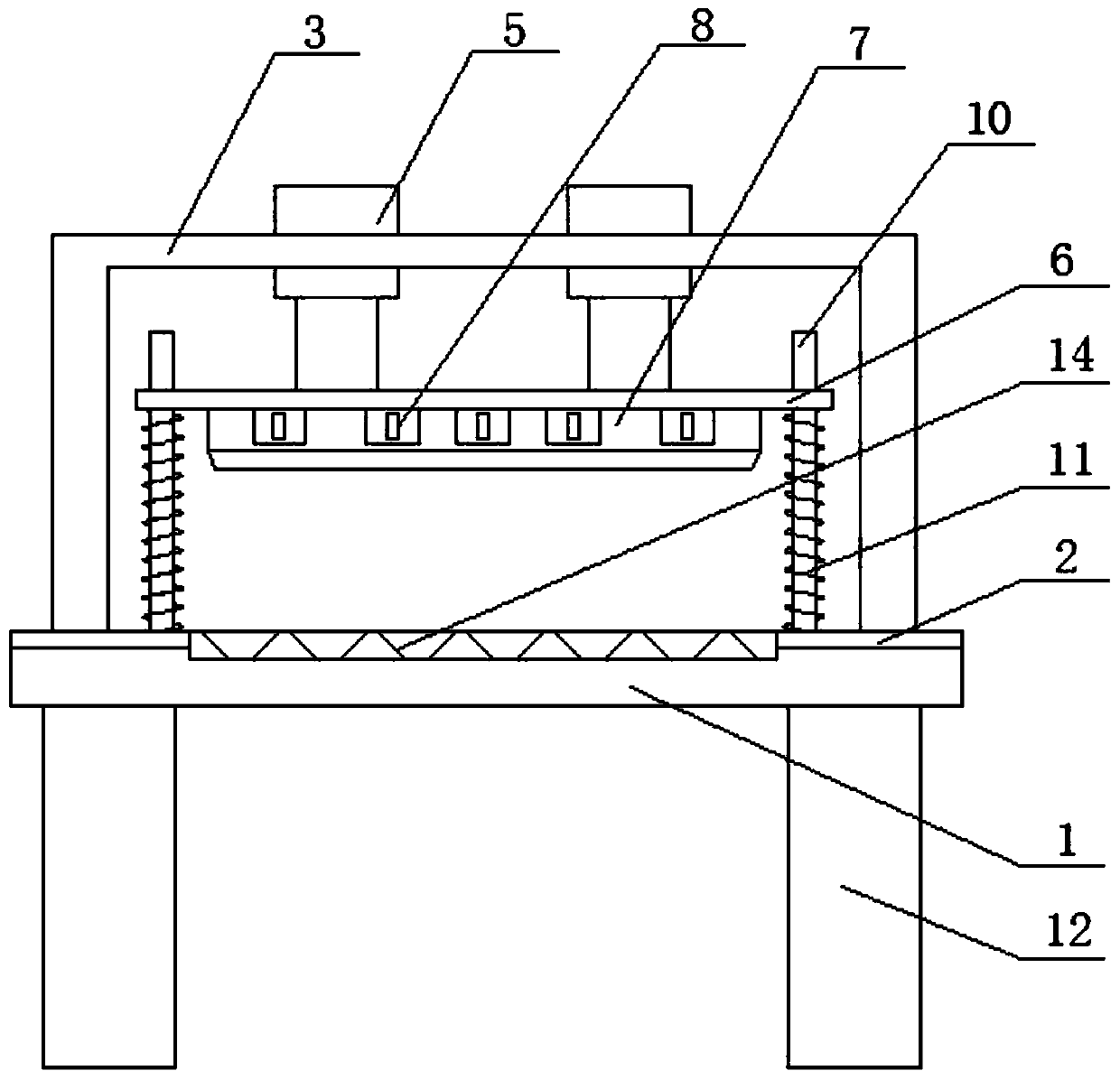

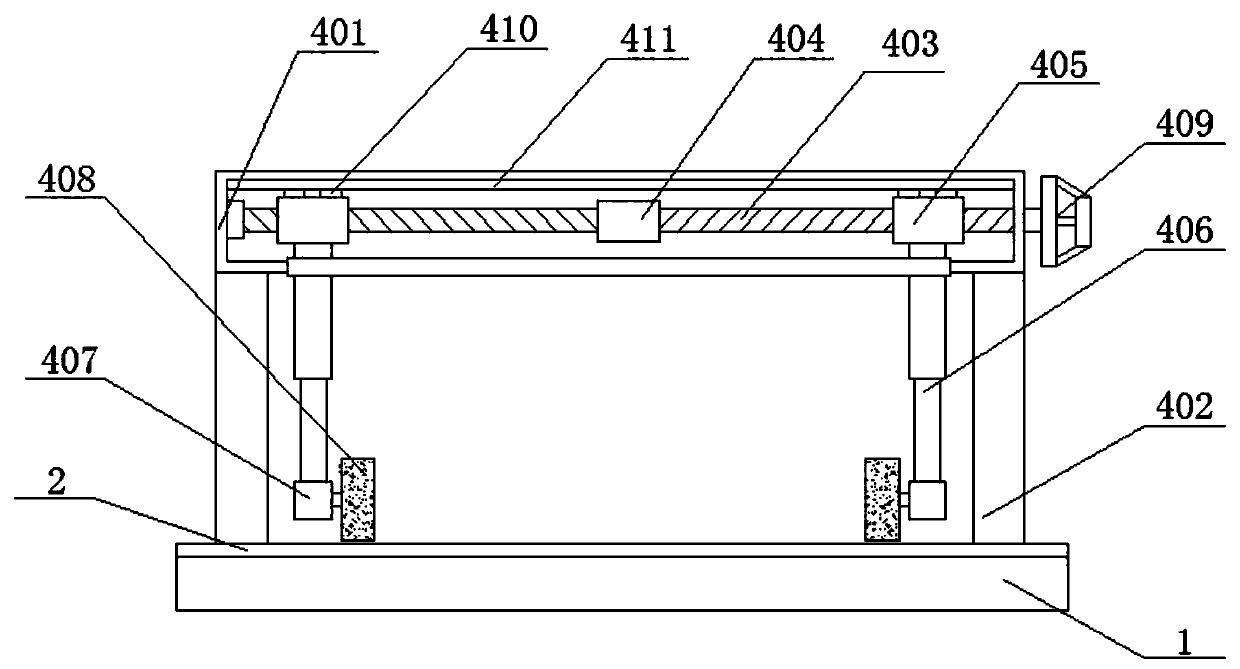

Cloth cutting machine for clothes processing

ActiveCN107630346AGuaranteed cloth cutting effectHeight adjustableSevering textilesMetal working apparatusPulp and paper industryMaterial resources

The invention discloses a cloth cutting machine for clothes processing. The cloth cutting machine comprises a processing platform, wherein a stainless steel plate is arranged at the top of the processing platform and a cloth cutting frame is arranged at one side of the top of the stainless steel plate; a material guide device is arranged at one side of the cloth cutting frame; a first electric retractable rod penetrates through the top of the cloth cutting frame; a supporting plate is arranged at the bottom end of the first electric retractable rod; a cutter is arranged at the bottom of the supporting plate; a fixing device is arranged at one side of the cutter; a clamping device is arranged at the other side of the cutter; guide rods are arranged at two sides of the supporting plate; thecloth cutting machine relates to the technical field of the clothes processing. The cloth cutting machine for the clothes processing can be used for rapidly detaching the cutter; heating wires are arranged at two sides of a cutter groove so that unnecessary economic wastes are avoided and the manpower and material resources are saved; the height and the width of a friction wheel can be adjusted sothat the cloth cutting machine is suitable for cloth with any specification; a condition that the cloth has folds in a cloth cutting process is prevented; the cloth cutting effect of the cloth cutting machine is ensured and the utilization standards of users can be met.

Owner:沈丘县永盛服饰有限公司

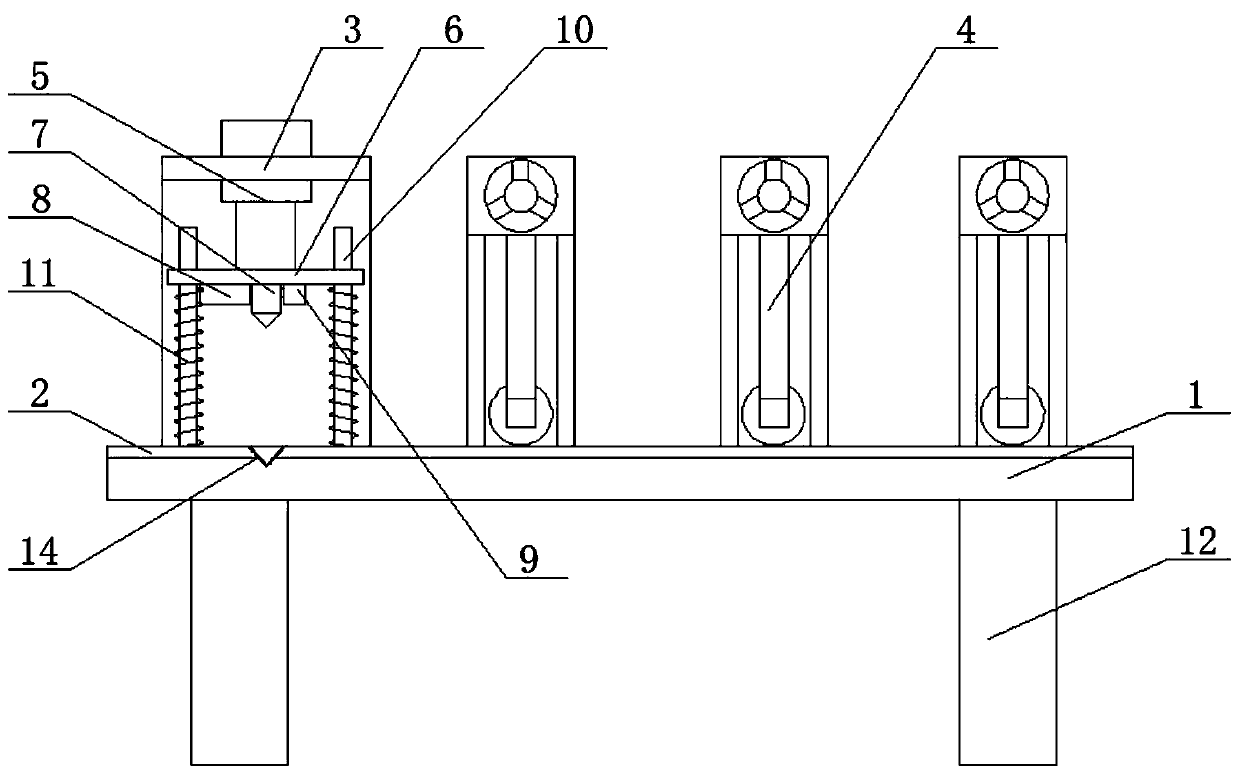

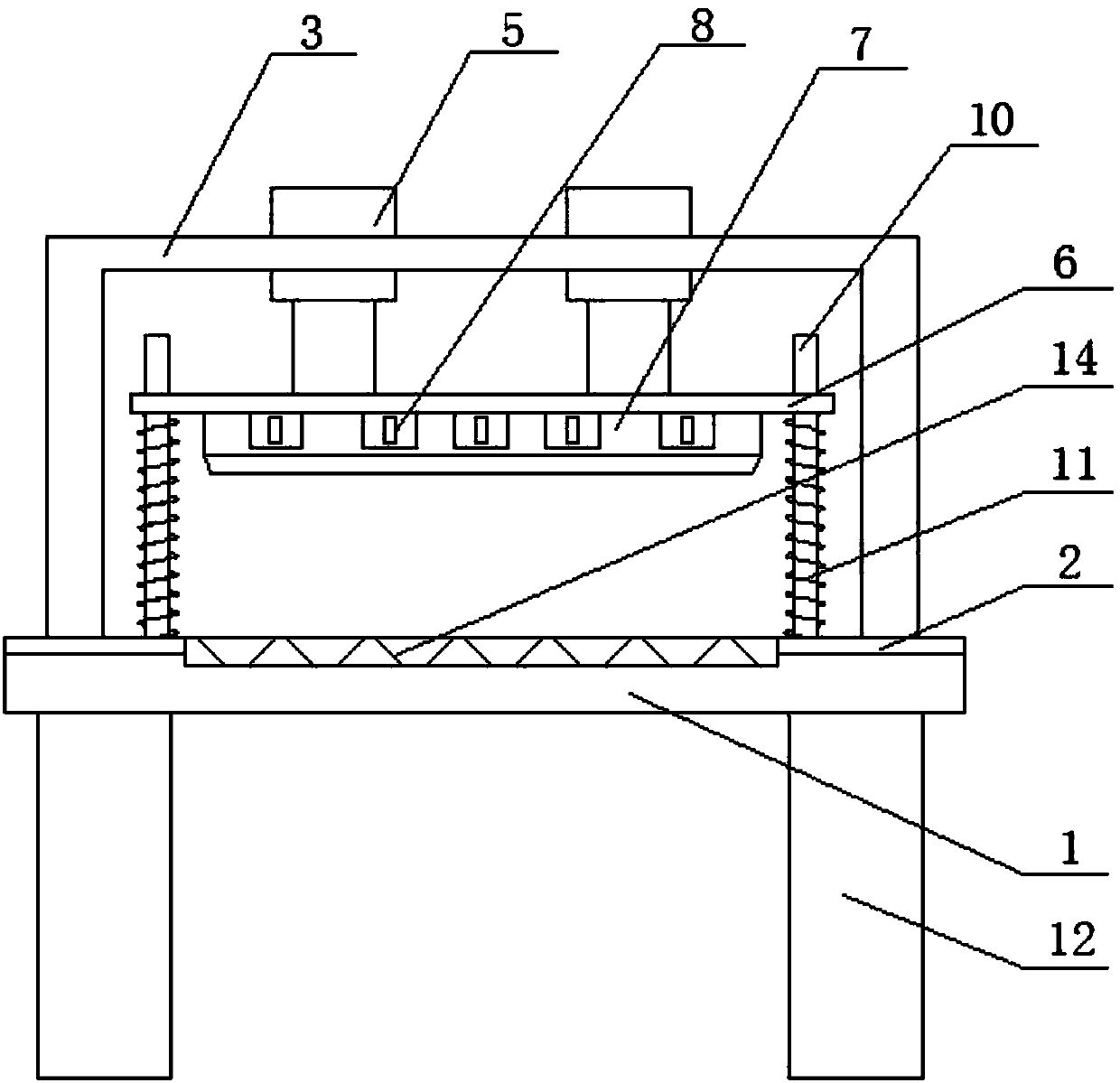

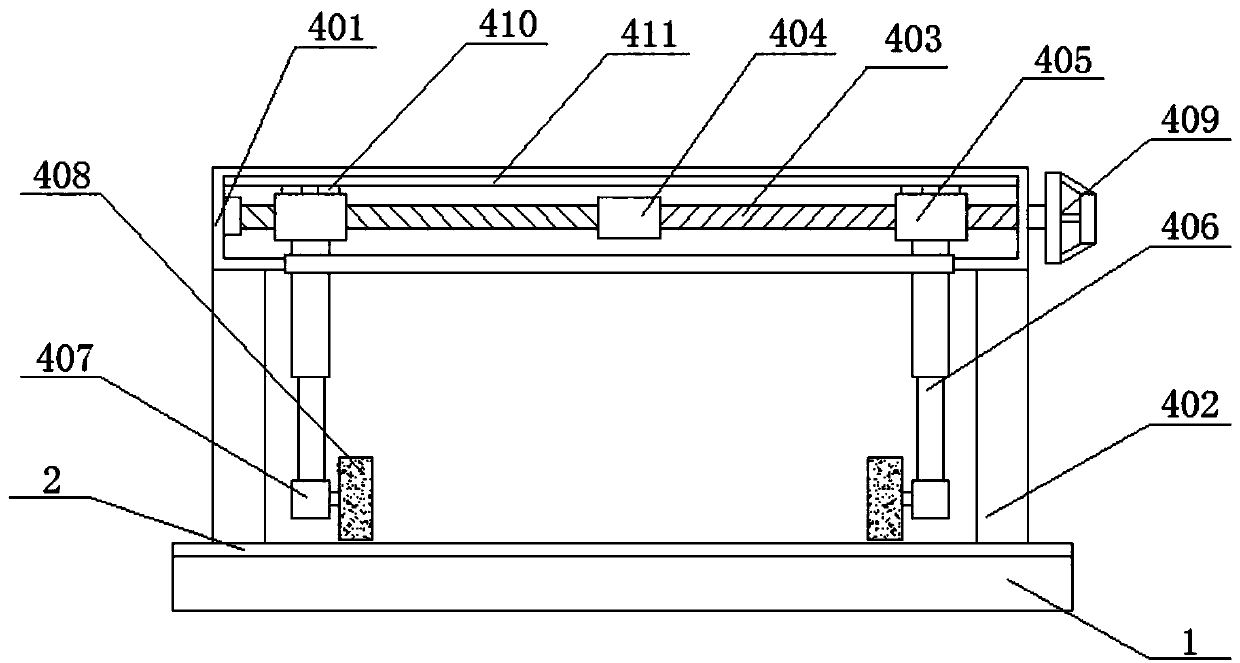

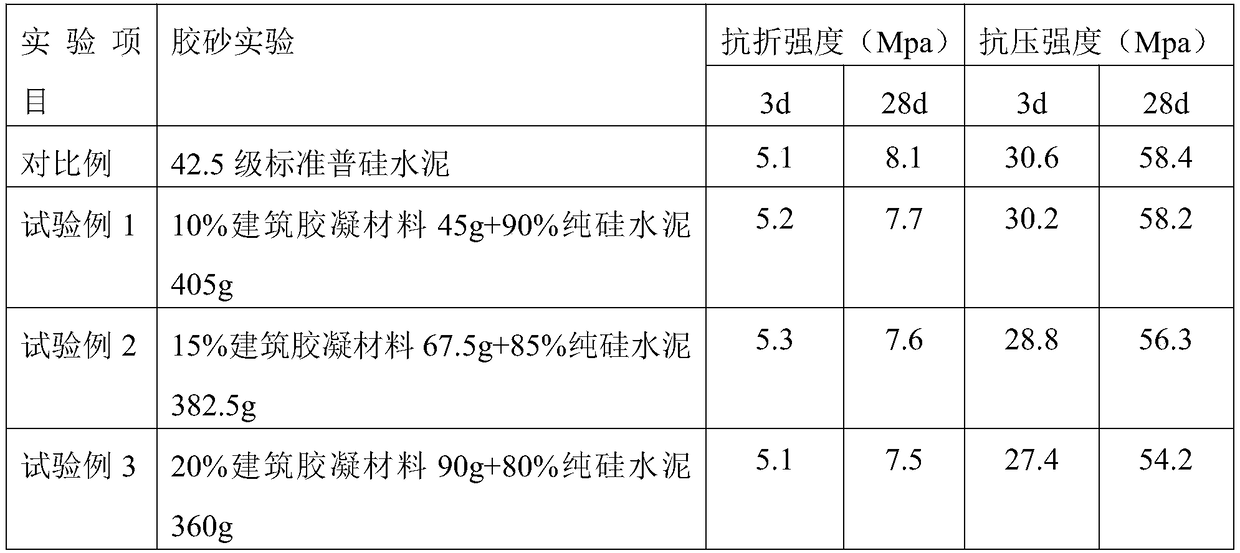

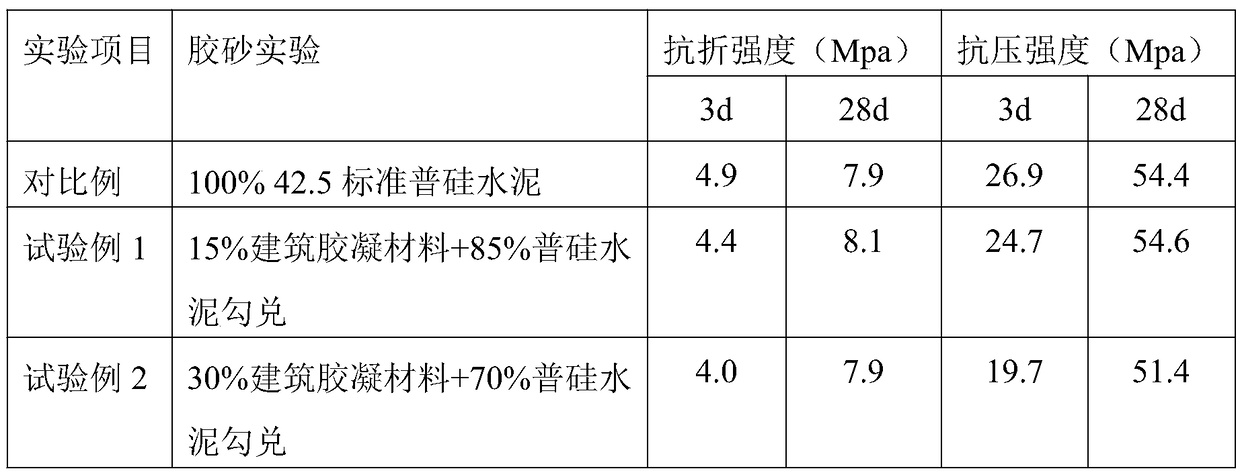

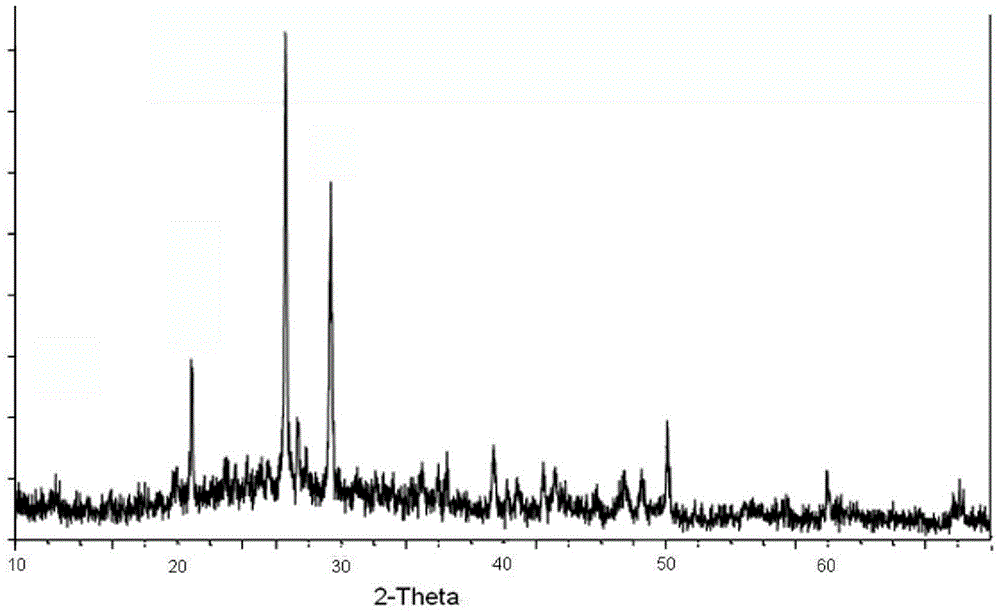

Constructional binding material and construction material

PendingCN109180030ASolving RecyclingHigh content of active ingredientsCement productionSlagBULK ACTIVE INGREDIENT

The invention provides a constructional binding material made by utilizing refined steel slag and industrial residues and a construction material made by utilizing the constructional binding material.The constructional binding material is made by mixing and grinding stainless steel refined steel slag and industrial residues, wherein the stainless steel refined steel slag is AOD (Argon Oxygen Decarburization) furnace steel slag while smelting stainless steel; and the industrial residues refer to steel plant residues and / or steel slag tailings. The construction material is made by mixing the constructional binding material and cement or concrete. According to the constructional binding material and the construction material provided by the invention, the problem that the stainless steel refined steel slag cannot be recycled can be effectively solved. Moreover, the constructional binding material is high in content of active ingredients, and during practical application, the use intensity of the construction material can be effectively improved, and the timeliness of the use intensity is prolonged.

Owner:广西北港新材料有限公司

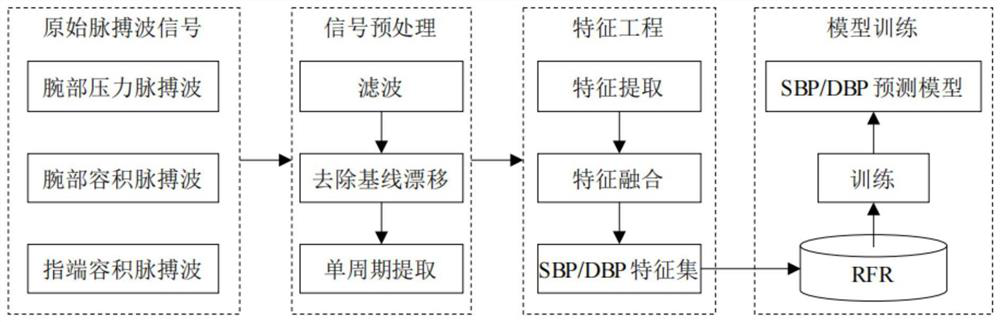

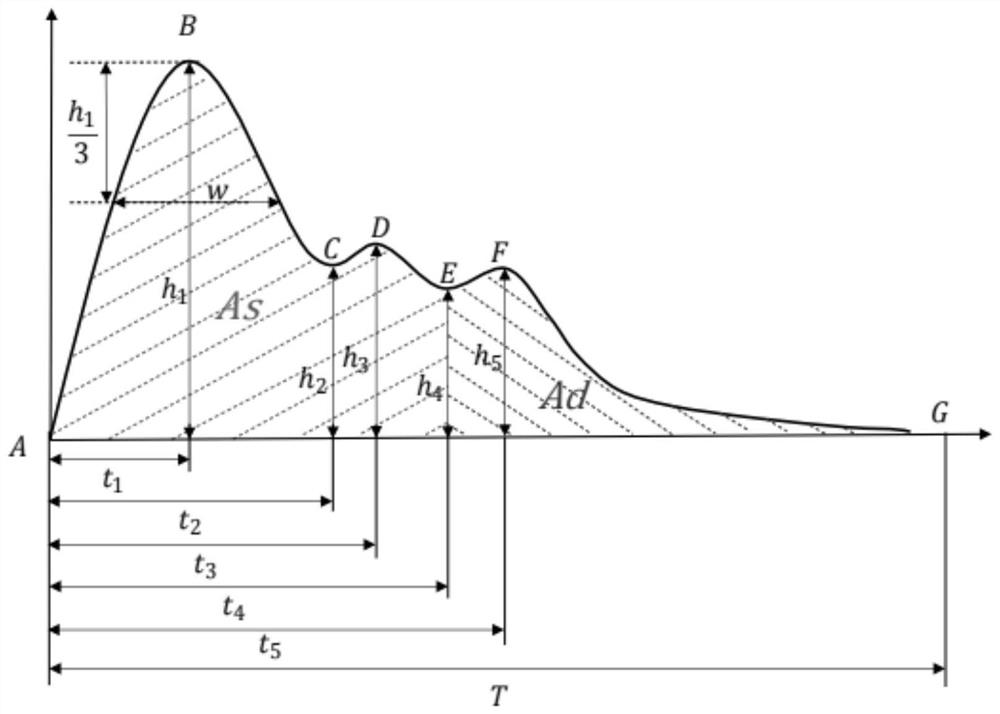

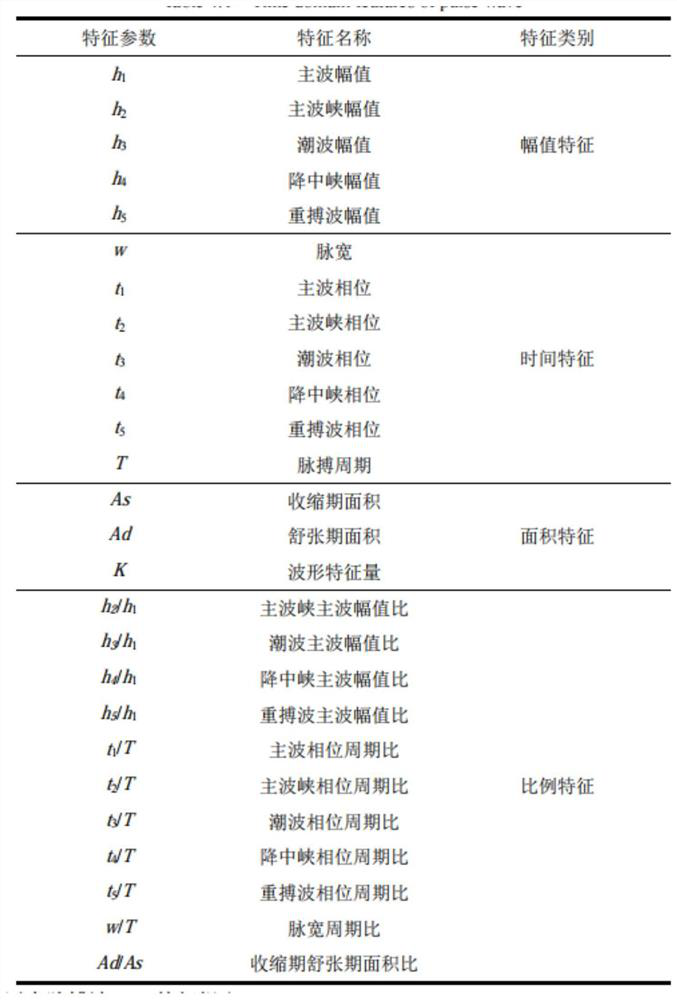

Blood pressure prediction method based on feature fusion

PendingCN113598737AAccurate predictionAccurate and Effective PredictionEvaluation of blood vesselsSensorsFeature setFeature fusion

The invention discloses a blood pressure prediction method based on feature fusion. The method comprises the steps that original pulse wave signals are collected; the original pulse wave signals are sequentially subjected to preprocessing such as filtering, baseline drift removal and single-cycle extraction, so that processed pulse wave signals are obtained; feature extraction is conducted on the pulse wave signals processed in the step 2 to obtain time domain features of the preprocessed pulse wave signals, amplitude change features of pressure pulse waves under different levels of pressure and volume pulse wave conduction speed, and screening and fusion of the features are completed based on an embedded feature selection method, so that a feature set used for blood pressure prediction is obtained; the feature set is trained based on a random forest regression algorithm to obtain SBP and DBP prediction models; and the blood pressure is predicted by using the SBP and DBP prediction models. According to the method, accurate and effective prediction of SBP and DBP is achieved, the AAMI use standard can be met, and the method has the advantage of being accurate in prediction.

Owner:SHANGHAI UNIV OF T C M +1

Low-odor, low-emission and flame-retardant composite material and preparation method thereof

The invention provides a low-odor, low-emission and flame-retardant composite material and a preparation method thereof, and relates to the technical field of high polymer materials. The low-odor, low-emission and flame-retardant composite material provided by the invention is prepared from the following raw materials: modified polypropylene, an inorganic filler, glass beads, modified sepiolite, amodified tourmaline powder, a lubricant, zinc stearate, a coupling crosslinking agent and an antioxidant. The polypropylene composite disclosed by the invention is a low-emission organic (benzenes and aldehydes and like eight substances are low) material with good flame retardance and low odor; the material provided by the invention can be extensively applied to the automobile industry, especially the exterior and interior decoration materials of the new energy automobile, is free from environment pollution, green and environment-friendly, and capable of guaranteeing the human health of the user.

Owner:WUHU CHUANGKE NEW MATERIAL TECH CO LTD

Melt-blown polypropylene material composition and preparation method thereof

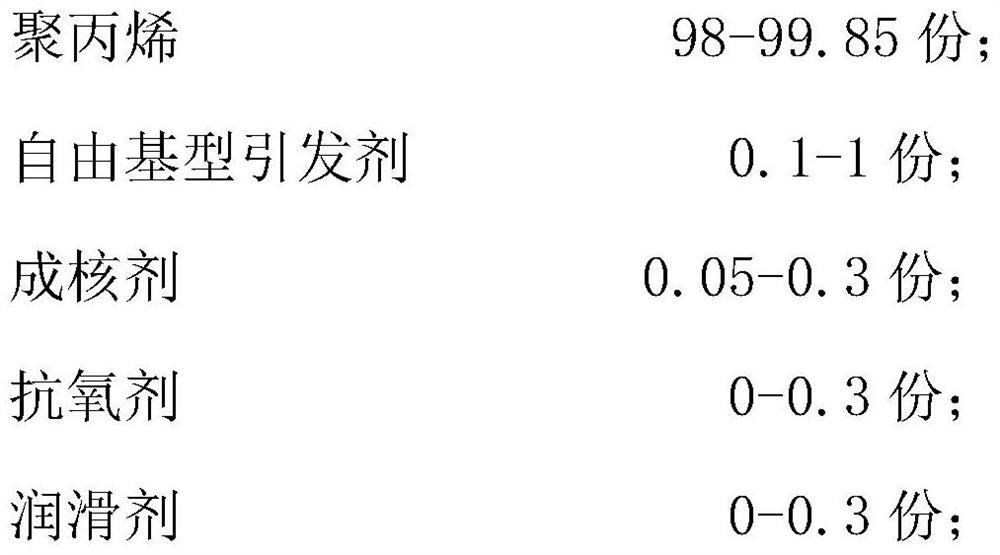

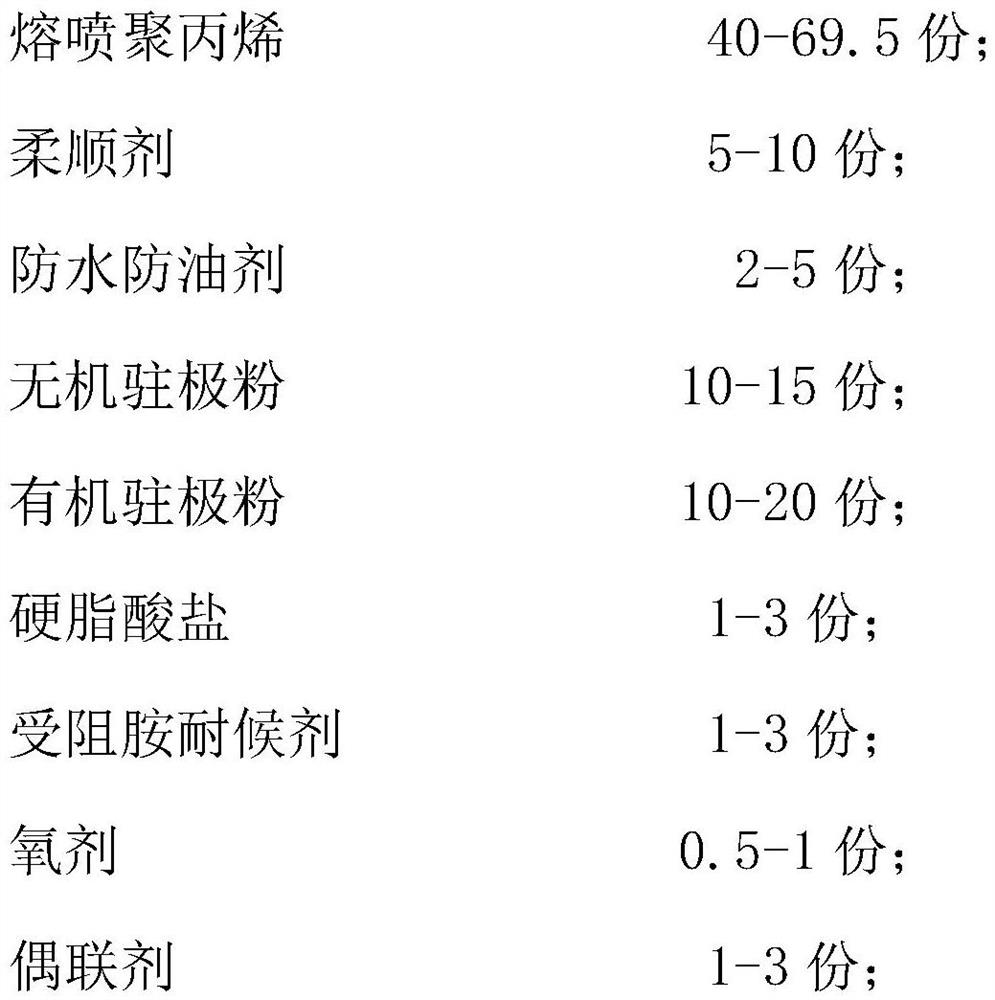

PendingCN112812429AMoisture absorption and long-lasting power lockMeet the use standardNon-woven fabricsMonocomponent polyolefin artificial filamentHindered amine light stabilizersPolypropylene

The invention discloses a melt-blown polypropylene material composition and a preparation method thereof. The melt-blown polypropylene material composition comprises 95-99 parts of a melt-blown polypropylene material and 1-5 parts of electret master batch. The melt-blow polypropylene material is prepared from the following components in parts by weight: 98 to 99.85 parts of polypropylene, 0.1 to 1 part of free radical type initiator, 0.05 to 0.3 part of nucleating agent, 0 to 0.1 part of antioxidant and 0 to 0.3 part of lubricant. The electret master batch comprises the following components: 40-69.5 parts of melt-blown polypropylene, 2-5 parts of a waterproof and oil-proof agent, 5-10 parts of a softener, 10-15 parts of inorganic electret powder, 10-20 parts of organic electret powder, 1-3 parts of stearate, 1-3 parts of a hindered amine weather-resistant agent, 0.5-1 part of an antioxidant and 1-3 parts of a coupling agent. As the waterproof and oil-proof agent, the softener, the hindered amine weather-proof agent and the antioxidant can react with the free radical initiator in the melt-blown material system, the melt-blown polypropylene and the electret master batch are independently produced and mixed for use. According to the preparation method, a UV lamp box is placed before pelletizing, material strips are irradiated by a UV lamp, peroxide residues which do not react completely are completely cleaned, and zero peroxide residues are achieved.

Owner:广东国恩塑业发展有限公司

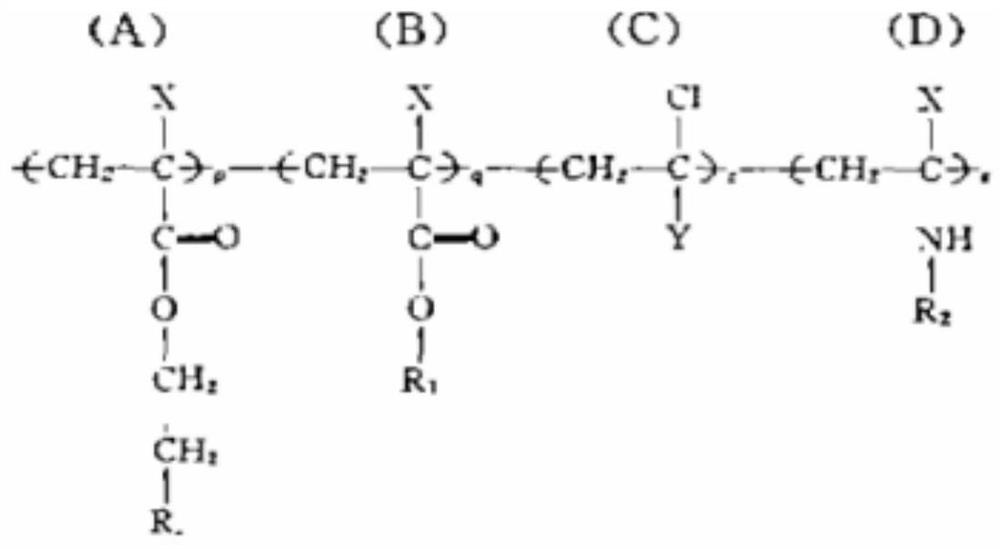

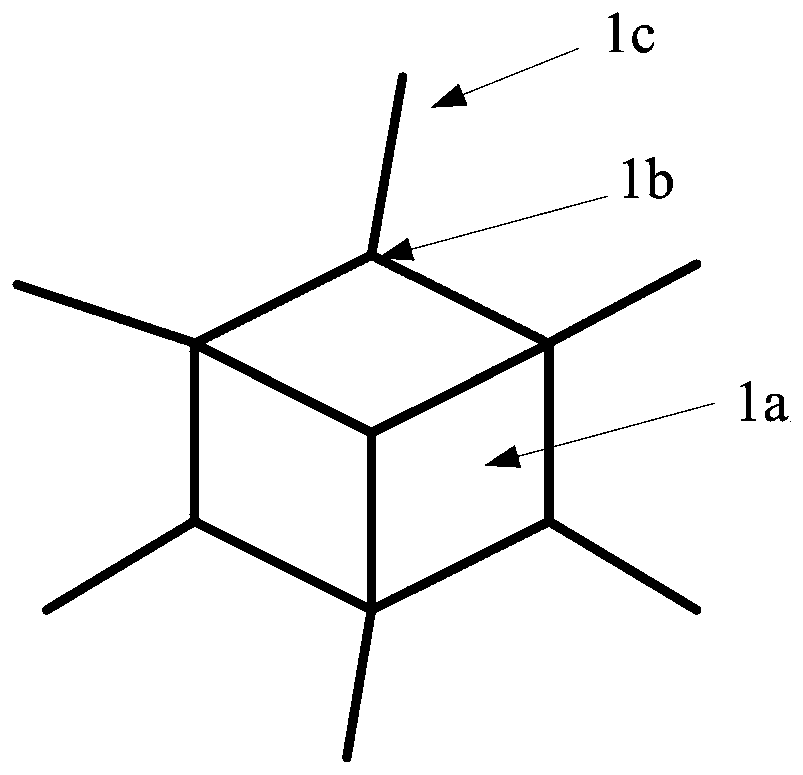

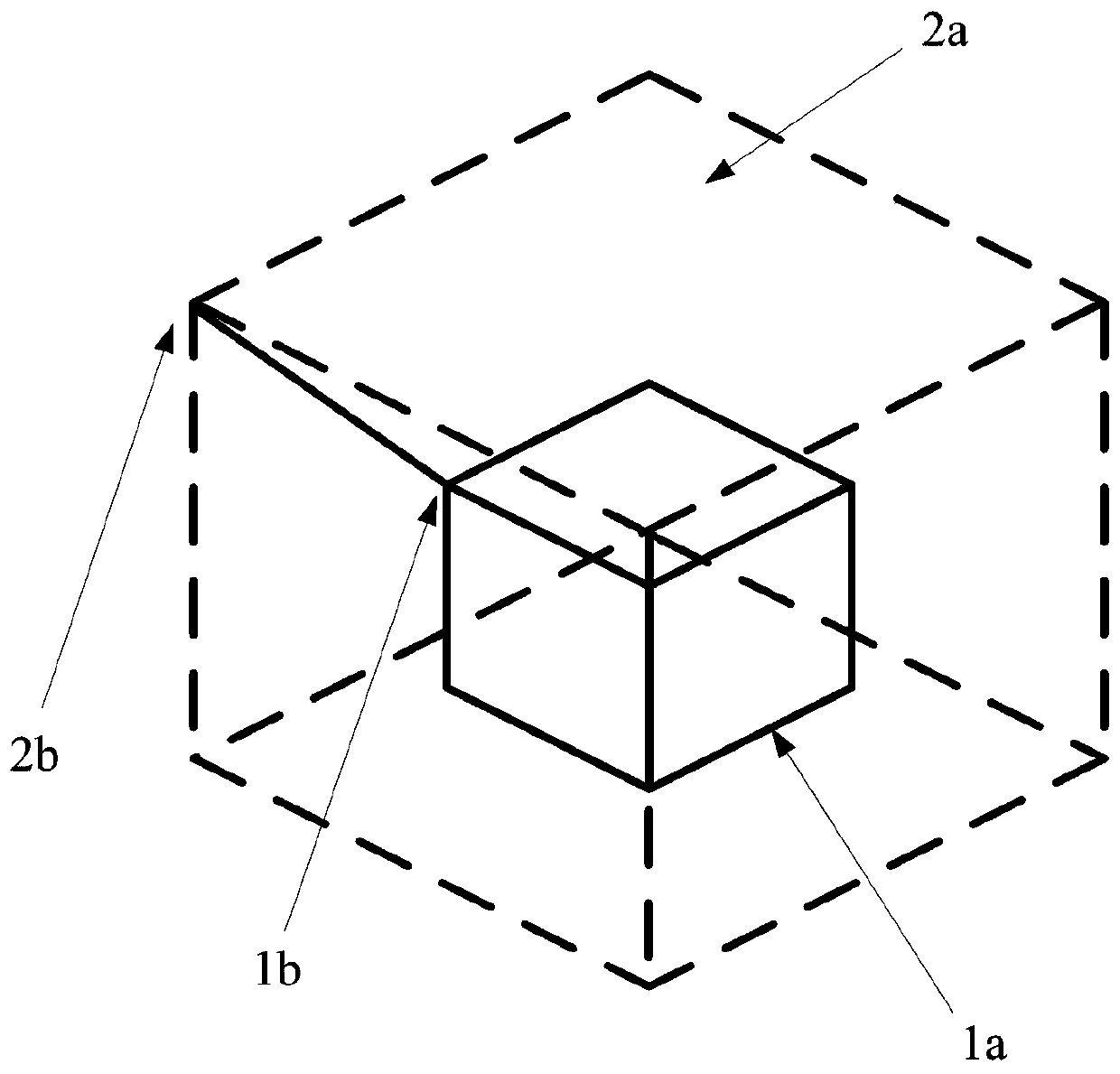

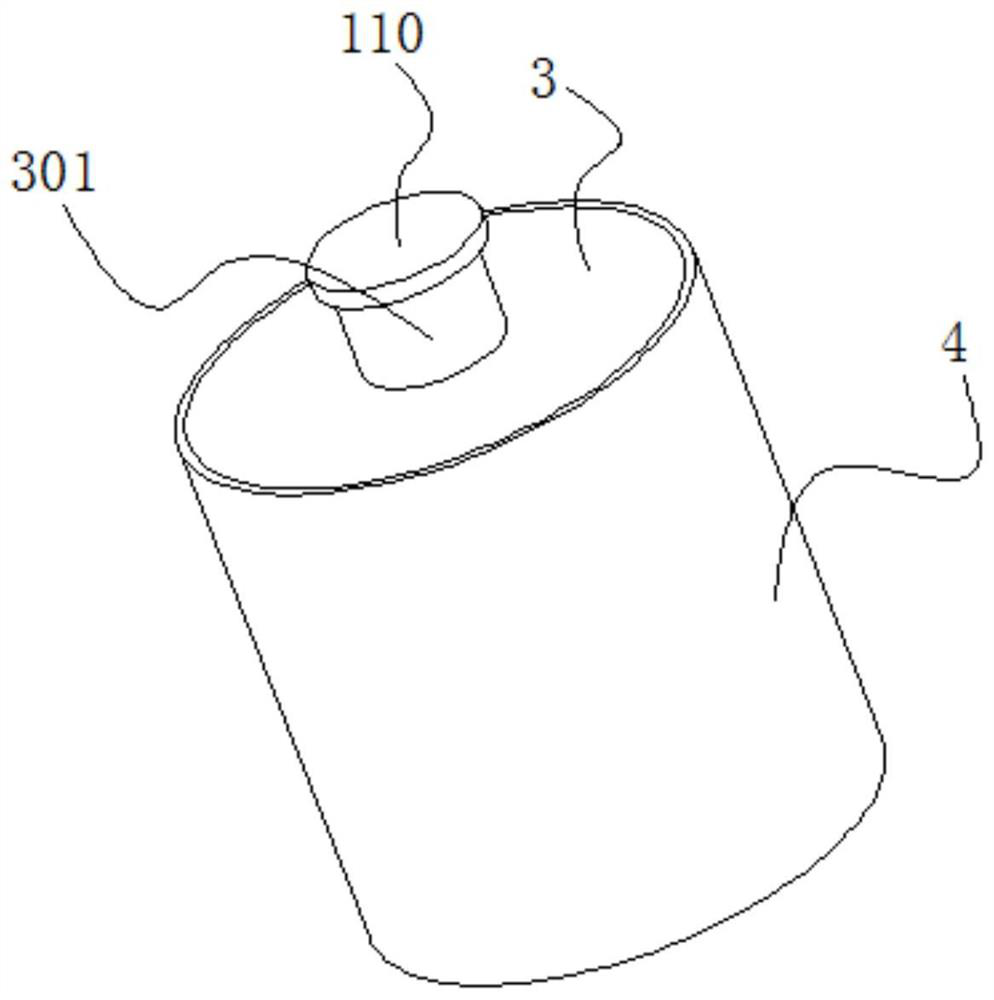

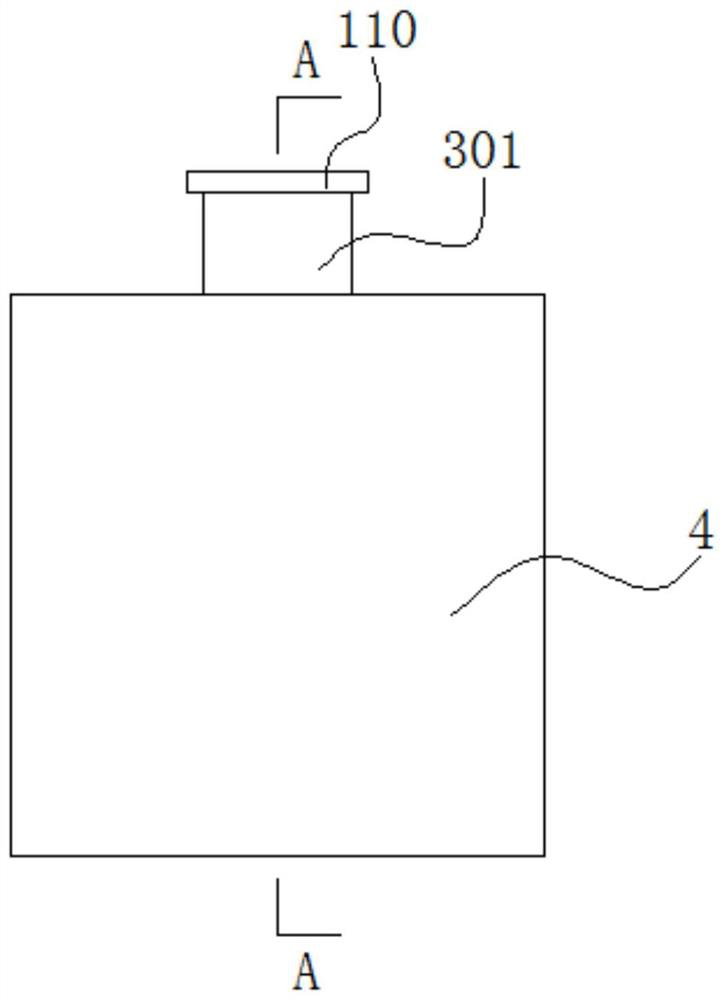

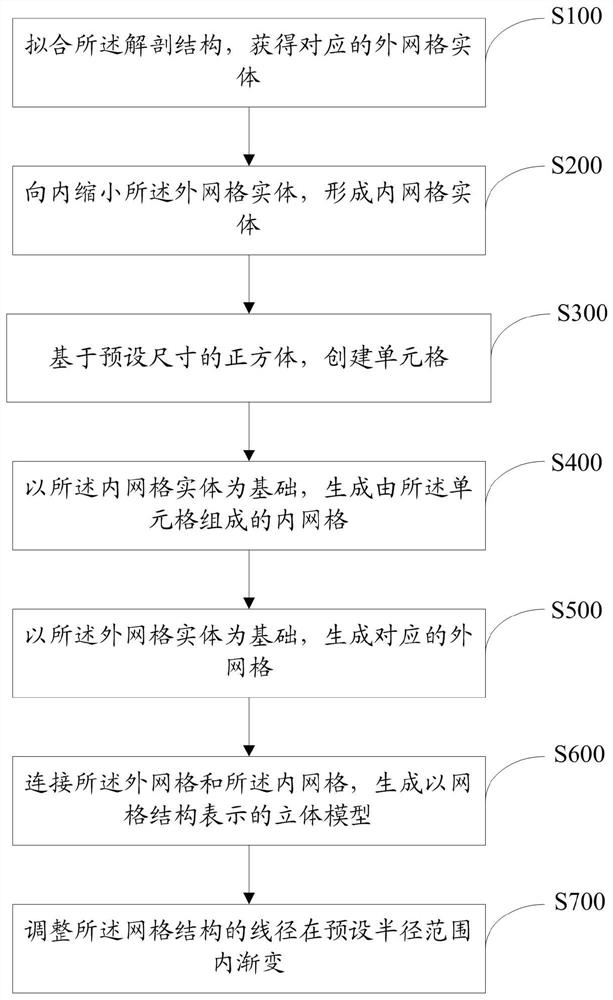

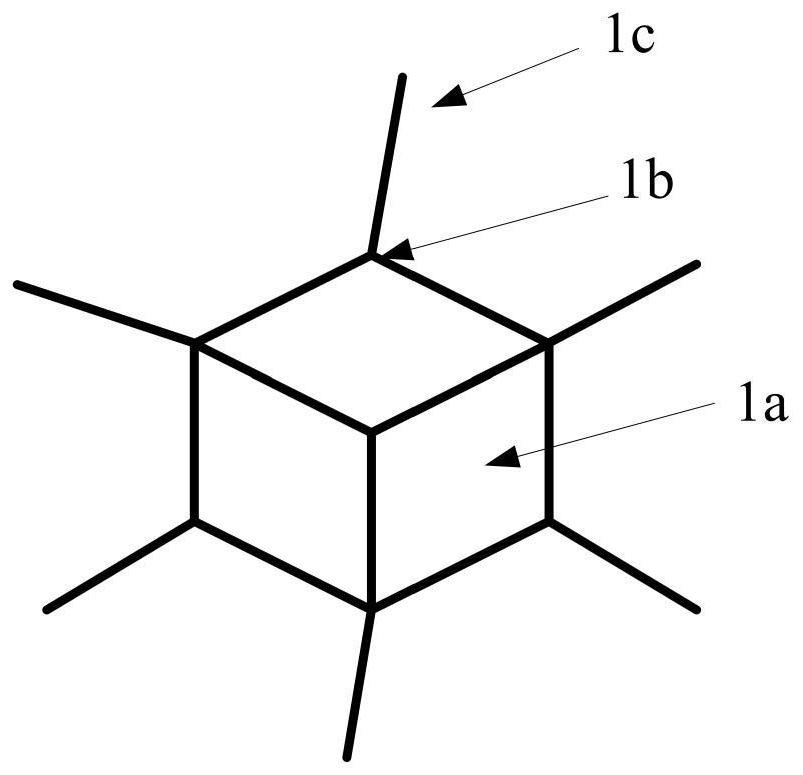

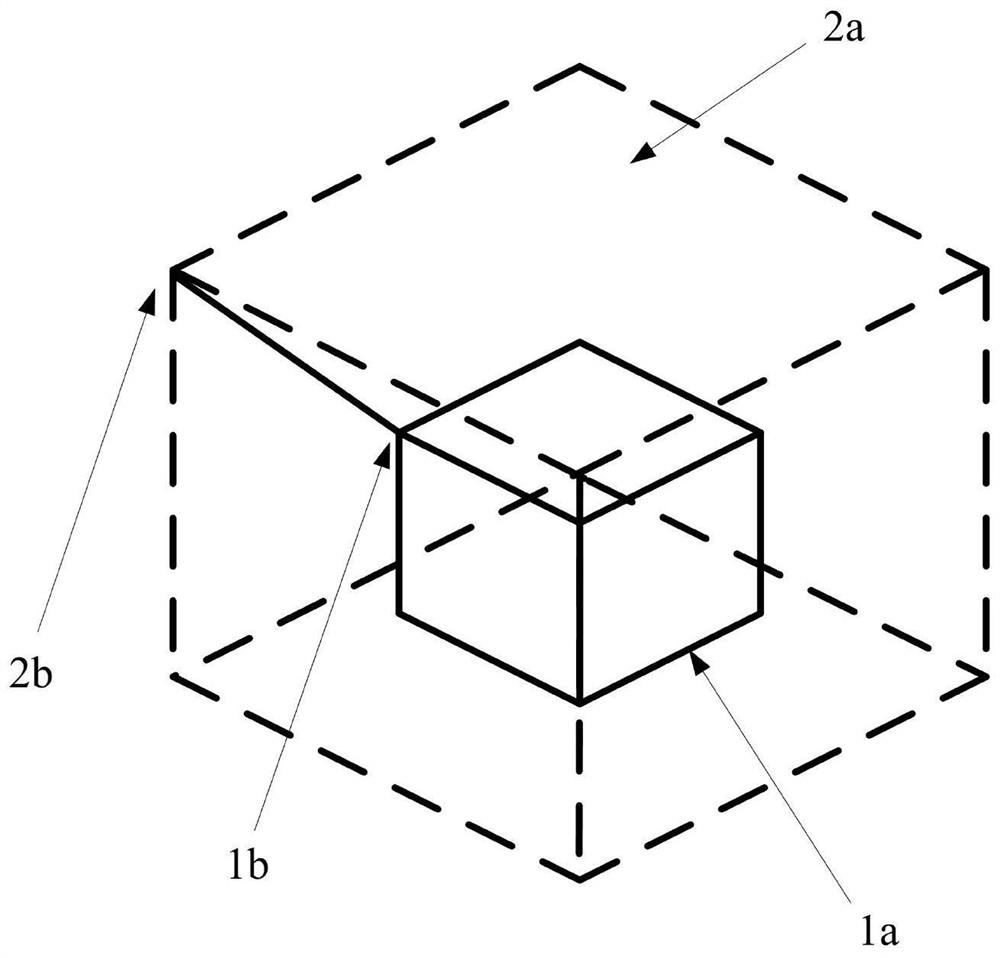

Stereoscopic model construction method of anatomical structure and repairing body of anatomical structure

ActiveCN110292466AEasy to printImprove securityBone implantJoint implantsAnatomical structuresComputer science

The embodiment of the invention discloses a stereoscopic model construction method of an anatomical structure and a repairing body of the anatomical structure. The method comprises the steps of fitting the anatomical structure to obtain a corresponding outer grid entity; shrinking the outer grid entity inwards to form an inner grid entity; creating cells on the basis of a cube of a preset size; with the inner grid entity as the basis, generating an inner grid composed of the cells; with the outer grid entity as the basis, generating a corresponding outer grid; connecting the outer grid and theinner grid, and generating a stereoscopic model represent by the grid structure. By means of the method, the stereoscopic three-dimensional model of the grid structure can be formed. The stereoscopicmodel can well fit the focus area or the three-dimensional stereoscopic shape required for reconstruction repairing.

Owner:SHENZHEN EXCELLENT TECH

Novel sheet metal cutting machine

InactiveCN106514267ASimple cutting processSimplify manual operationsOther manufacturing equipments/toolsLarge fixed membersEngineeringMetal

The invention discloses a novel sheet metal cutting machine. The novel sheet metal cutting machine comprises a bearing plate, two supporting legs fixed to the lower end of the bearing plate and two cutting tables installed at the upper end of the bearing plate; third drivers are installed in the two supporting legs and are connected to electrically-controlled lifting rods through speed regulators, the electrically-controlled lifting rods penetrate through the bearing plate to be connected to the cutting tables, the supporting legs are provided with rotary knobs, and the rotary knobs are electrically connected to the speed regulators; the upper ends of the two cutting tables are connected through a fixed frame, two first drivers are installed at the top of the fixed frame, the bottoms of the first drivers are connected to cutting tools through telescopic devices, and the cutting tools face the surfaces of the cutting tables; and sliding rails are arranged on the transverse edges on the surface of each cutting table, and two limiting rods are installed between the sliding rails. The cutting process is simple, manual operation is easy, the cutting efficiency of sheet metal is high, and the metal is prevented from sliding in the cutting process.

Owner:苏州瑞升利金属制品有限公司

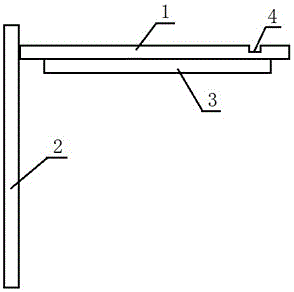

Table special for limo

Owner:成都原景旅居科技有限公司

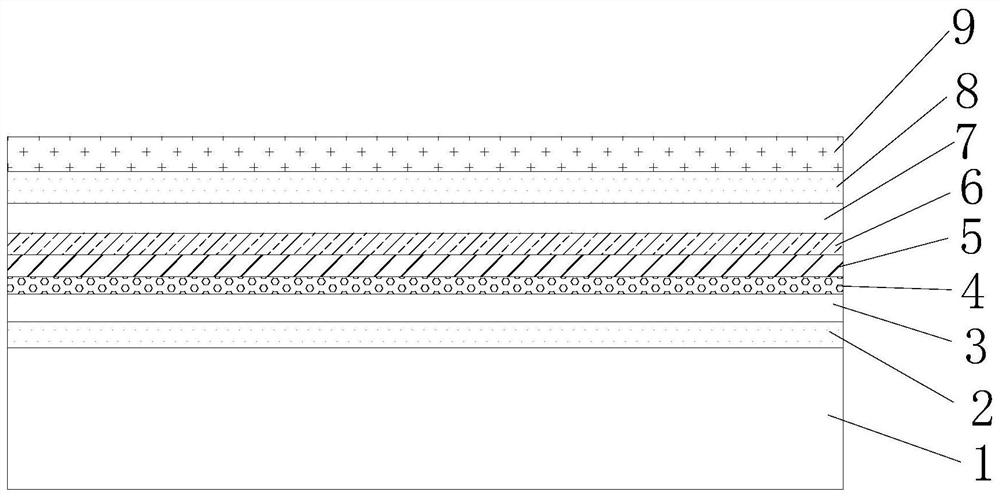

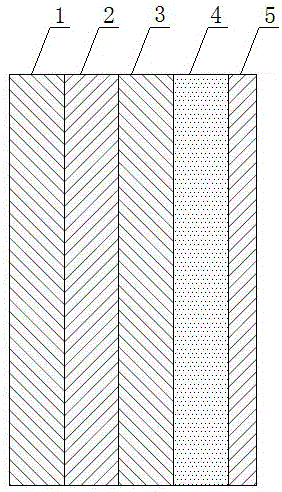

Passive low-energy-consumption offline temperable LOW-E coated glass and preparation process thereof

The invention discloses passive low-energy-consumption offline temperable LOW-E coated glass, which comprises a glass substrate, and a first dielectric layer, a second dielectric layer, a metal silver layer, a first shielding layer, a second shielding layer, a third dielectric layer, a fourth dielectric layer and a fifth dielectric layer are sequentially sputtered on the glass substrate from bottom to top, wherein the first dielectric layer and the fourth dielectric layer are silicon nitride layers, the second dielectric layer and the third dielectric layer are zinc oxide layers, the fifth dielectric layer is a zirconium oxide layer, the first shielding layer and the second shielding layer are a nichrome layer and a nichrome layer respectively, and the preparation process adopts high-vacuum magnetron sputtering coating equipment for layer-by-layer coating. The five dielectric layers are adopted, the visible light transmittance of the film layer is effectively increased, it is guaranteed that the film layer has a good anti-damage effect, the shielding layer effectively protects the silver layer, and the oxidation resistance of the silver layer is improved; the visible light transmittance of the low-emissivity glass is not lower than 89%, the emissivity is not larger than 0.095, and the use standard of passive low-energy-consumption buildings is met.

Owner:ANHUI FENGYANG GLASS

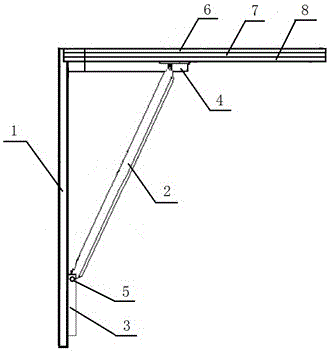

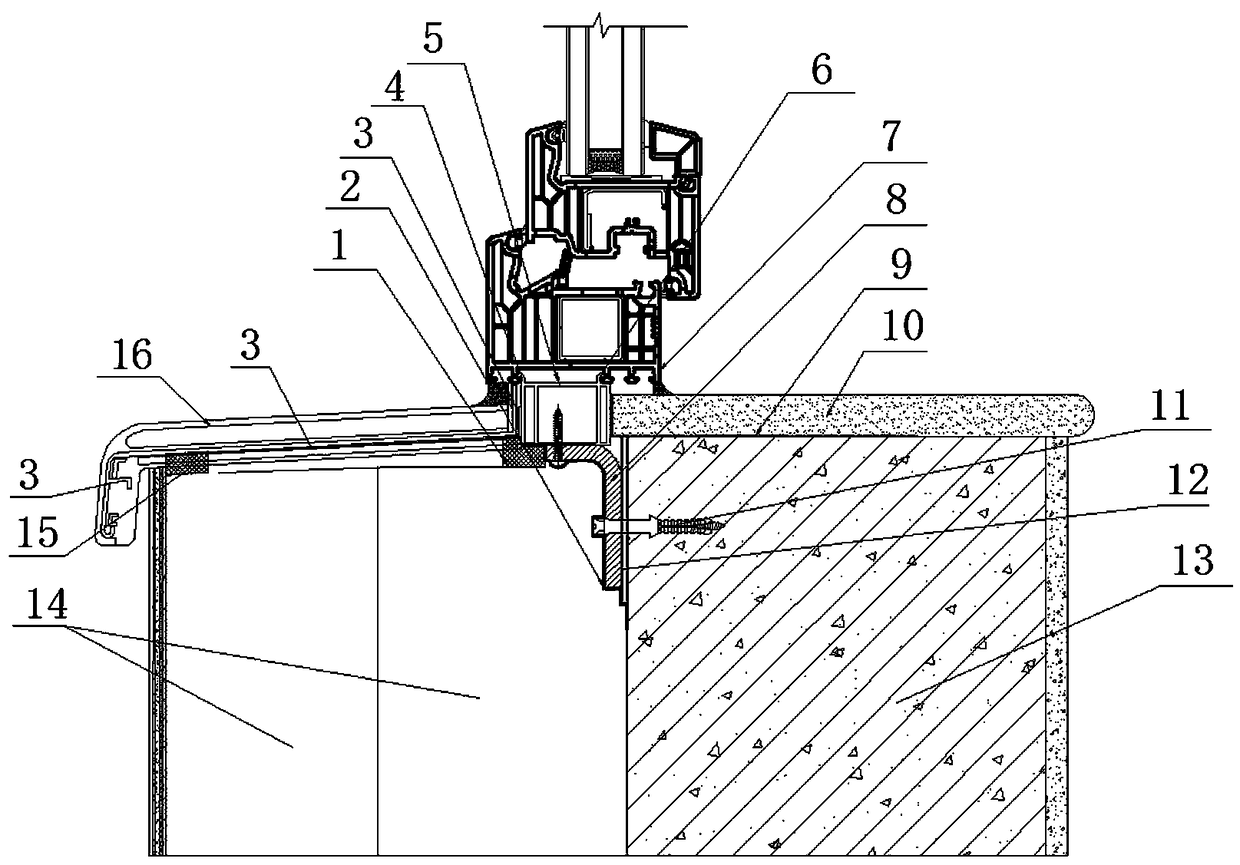

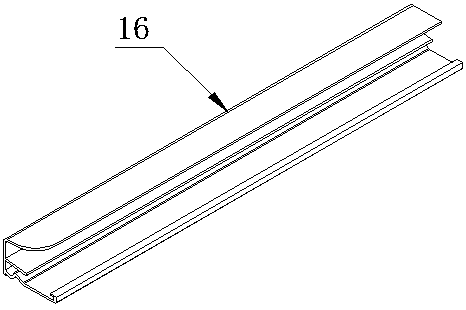

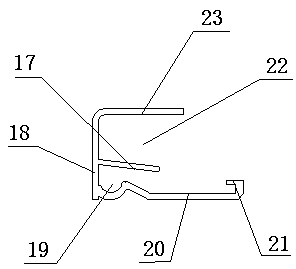

A window frame installation structure for passive house windows

ActiveCN106854960BImprove waterproof performanceReduce manual levelingFrame fasteningSills/thresholdThermal insulationGraphite

The invention discloses a passive window frame installation structure of house windows. The outer end surface of the wall body is fixed to a graphite polyphenyl support body. A vertical wall of an L-shape metal fixing plate is fixed to an upper part between the graphite polyphenyl support body and the outer end surface of the wall body. The upper end of a horizontal wall is fixed to a non-metal fixing block. A layer of waterproof breathable film is fixed between the non-metal fixing block and the graphite polyphenyl support body. A batch plate is abutted on the upper end of the graphite polyphenyl support body. The indoor side is fixed to the outer side wall of the non-metal fixing block. Pre-pressure expansion sealing belts are fixed between the indoor side lower end and the waterproof breathable film and the graphite polyphenyl support body. The outdoor side and the outer edge of the graphite polyphenyl plate are fixedly provided with pre-pressure expansion sealing belts. The upper end of the wall body is fixedly provided with an indoor windowsill plate. The window frame is buckled in two buckling hooks of the non-metal fixing block, and is fixed to the non-metal fixing block. The window using the passive window frame is not prone to generate cracks, and has good air tightness and water tightness, the leakage possibility is low, the thermal insulation property is strong, and the coefficient of heat transfer is low.

Owner:HEBEI ORIENT SUNDAR WINDOW

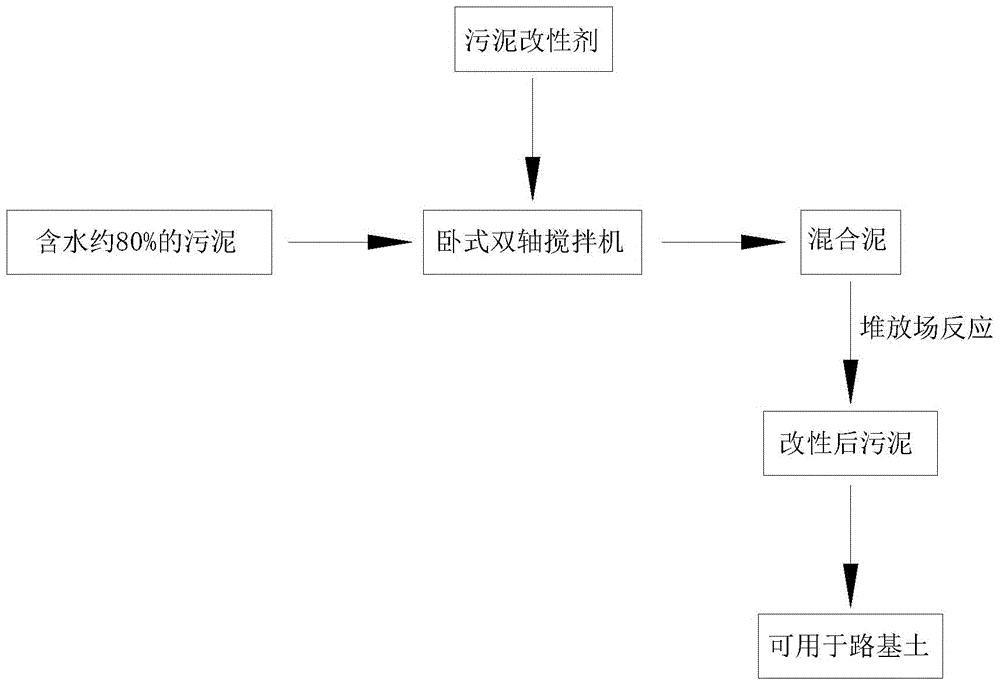

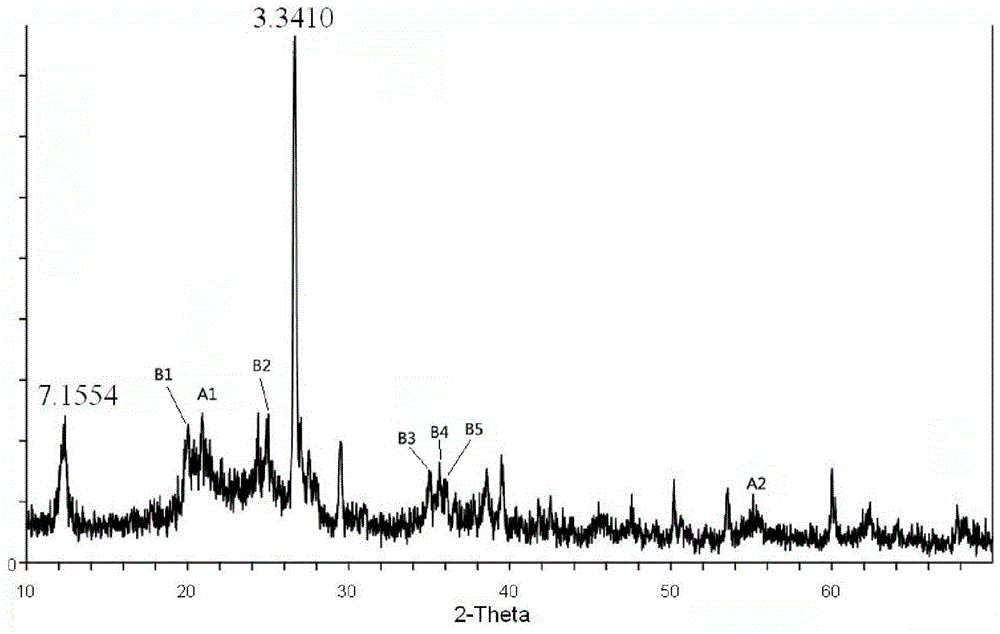

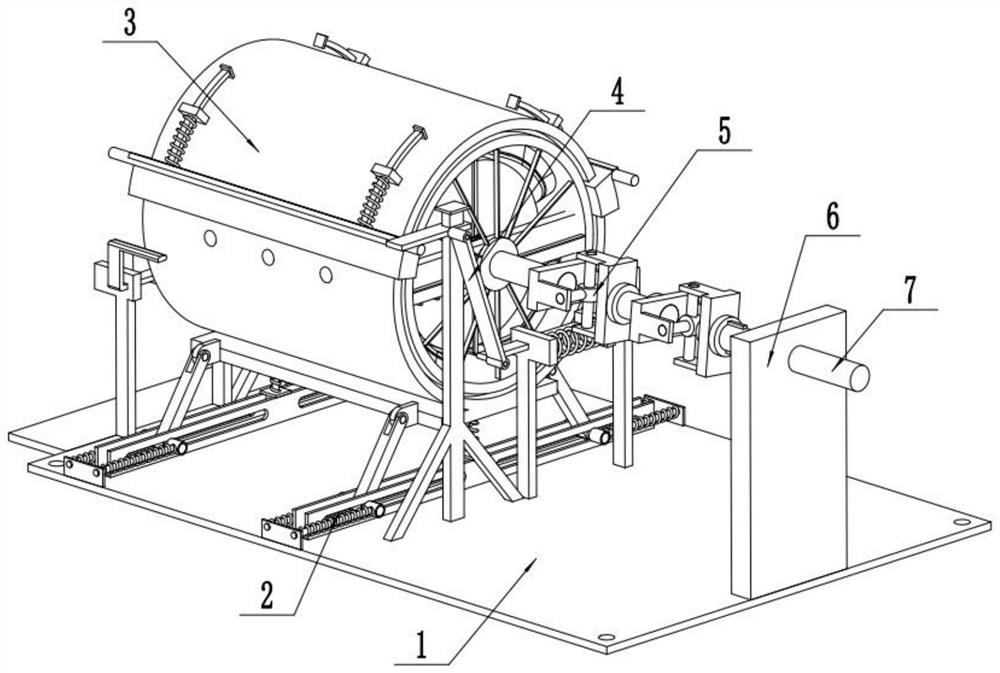

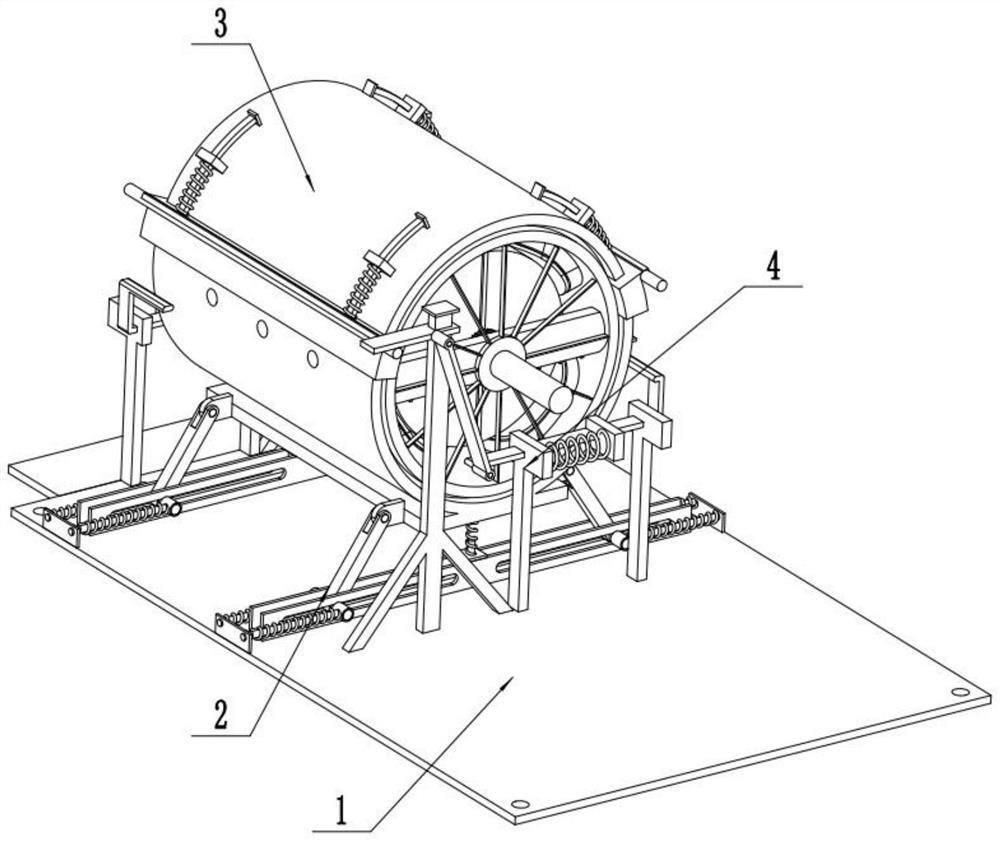

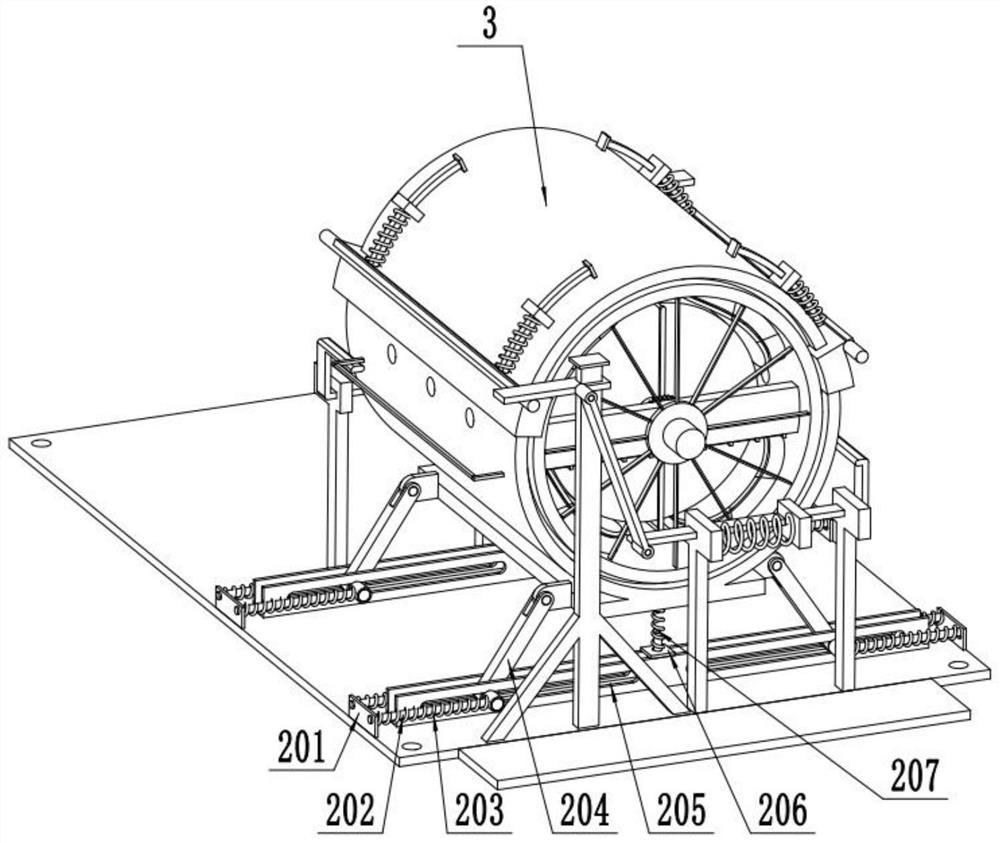

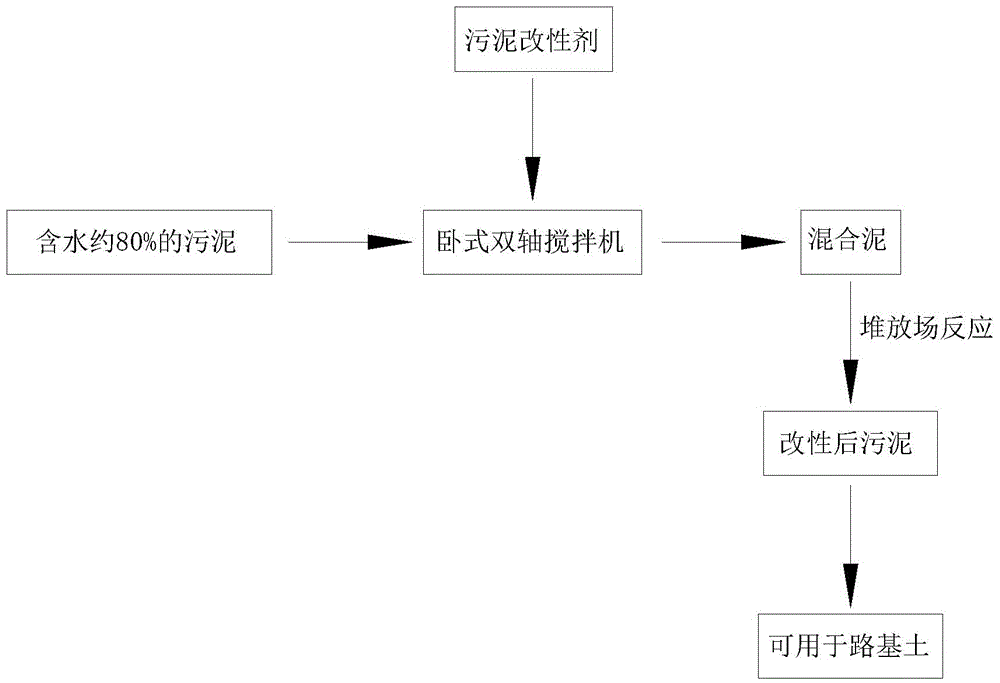

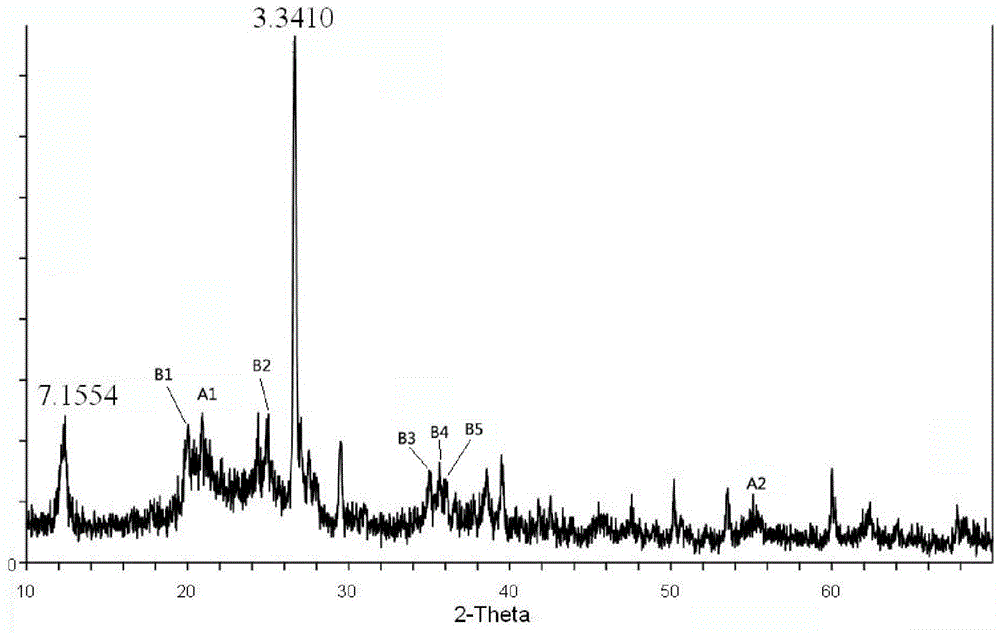

Sludge modifier, and method used for preparing subgrade soil from sludge via modification

ActiveCN104803567ARealize harmless treatmentSecondary sliming no longer occursSludge treatment by de-watering/drying/thickeningSludgeSilicon dioxide

The invention discloses a sludge modifier. The sludge modifier is prepared from 30 to 35% of silicon dioxide, 10 to 15% of aluminium oxide, 10 to 15% of iron trioxide, 30 to 35% of calcium oxide, and 3 to 5% of magnesium oxide via reaction at 1200 DEG C. The invention also discloses a method used for preparing subgrade soil from sludge via modification. According to the method, sludge with a water content of 80% is mixed with the sludge modifier at a mass ratio of 4:1-5:1; mixed sludge is obtained via stirring using a stirring device; and the mixed sludge is subjected to piling and curing, so that sludge of colloidal states is changed into sludge with crystal structures, and sludge is changed into subgrade soil. According to the method, complete modification of sludge is realized via adding of the sludge modifier, sludge is changed into subgrade soil, and no secondary argillization is caused; the method is simple, and is convenient to realize; and large scale industrialization can be realized.

Owner:GUANGZHOU ZHENGYUAN ENVIRONMENTAL ENG CO LTD

Medical miniature brushless motor

ActiveCN114530975AExtended service lifeMeet the use standardElectric machinesCooling/ventillation arrangementBrushless motorsElectric machinery

The invention discloses a medical miniature brushless motor, which belongs to the technical field of motors and comprises a base fixedly mounted in a motor shell, a track assembly is arranged on the base, a power output assembly is slidably mounted on the track assembly and comprises a winding mounting cylinder, and the winding mounting cylinder is slidably mounted on the track assembly. A rotor and a winding coil are arranged in the winding installation cylinder, air outlet holes are formed in the winding installation cylinder, a damping assembly is further fixedly installed on the base and used for controlling the opening size of the air outlet holes, and then the damping effect is achieved through the counter-acting force of airflow. According to the invention, the brushless motor can automatically realize the functions of heat dissipation and shock absorption in the use process, dust in the motor can be removed under the condition that the motor is not disassembled, the operation is simple, and the service life of the motor is prolonged.

Owner:江西昌龙电机有限公司

A rainwater circulation system based on sponge city

ActiveCN109319963BEasy to installEasy to removeGeneral water supply conservationIndustrial water supply conservationWater storageWater use

The invention discloses a rainwater circulation system based on a sponge city and relates to the technical field of the sponge city. The invention includes a water storage tank and a treatment well. The treatment well includes a well cover, a well body, a filter assembly and a fixing piece. The inner surface of the well body is ring-shaped and fixed side by side with nine splints. The nine splints are divided into three rows, and each row has three splints. There is a chute on the top, a support ring is fixed on the lower part of the shaft, and first guide holes are provided on the splint and the support ring. The present invention is equipped with a treatment well, which can perform filtration treatment when using water, solves the problem of sand and mud particles being discharged along with the water when the water is discharged, avoids the situation that the water end is easily damaged, and ensures that the discharged water can meet the needs of the user. It is easy to install and remove the filter plate and adsorption plate through the cooperation of splint, filter assembly and fixing parts, which is convenient for users to replace, clean and repair, and convenient for users to use.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

A three-dimensional model construction method of anatomical structure and its prosthesis

ActiveCN110292466BEasy to printImprove securityBone implantJoint implantsAnatomical structuresAnatomy

The embodiment of the invention discloses a method for constructing a three-dimensional model of an anatomical structure and a prosthesis thereof. Wherein, the method includes: fitting the anatomical structure to obtain a corresponding outer grid entity; reducing the outer grid entity inwardly to form an inner grid entity; creating a unit cell based on a cube with a preset size; Based on the inner grid entity, generate an inner grid composed of the cells; based on the outer grid entity, generate a corresponding outer grid; connect the outer grid and the inner grid , generating a solid model represented by a grid structure. This method can form a three-dimensional three-dimensional model of the grid structure. The three-dimensional model can well match the lesion area or the three-dimensional shape required for reconstruction and repair.

Owner:SHENZHEN EXCELLENT TECH

A kind of sludge modifier and the method for forming roadbed soil from modified sludge

ActiveCN104803567BRealize harmless treatmentSecondary sliming no longer occursSludge treatment by de-watering/drying/thickeningSludgeSilicon dioxide

The invention discloses a sludge modifier. The sludge modifier is prepared from 30 to 35% of silicon dioxide, 10 to 15% of aluminium oxide, 10 to 15% of iron trioxide, 30 to 35% of calcium oxide, and 3 to 5% of magnesium oxide via reaction at 1200 DEG C. The invention also discloses a method used for preparing subgrade soil from sludge via modification. According to the method, sludge with a water content of 80% is mixed with the sludge modifier at a mass ratio of 4:1-5:1; mixed sludge is obtained via stirring using a stirring device; and the mixed sludge is subjected to piling and curing, so that sludge of colloidal states is changed into sludge with crystal structures, and sludge is changed into subgrade soil. According to the method, complete modification of sludge is realized via adding of the sludge modifier, sludge is changed into subgrade soil, and no secondary argillization is caused; the method is simple, and is convenient to realize; and large scale industrialization can be realized.

Owner:GUANGZHOU ZHENGYUAN ENVIRONMENTAL ENG CO LTD

Cabinet door special for motor home

InactiveCN106223813AGood effectImprove space utilizationFireproof doorsVehicle with living accommodationMotor homeElectrical and Electronics engineering

The invention relates to the technical field of motor homes and in particular to a cabinet door special for a motor home. The cabinet door special for the motor home comprises a cabinet door, a cabinet body board and an attached board, wherein the upper end of the cabinet door is connected with the upper end of the cabinet body board in a movable manner; the height of the connecting end is equal to the length of the attached board; a cabinet door groove is formed in the outer surface of the cabinet door; the lower end of the inner surface of the cabinet door is connected with the attached board in a movable manner; the cabinet door and the attached board take a PVC foam board as a board core and take a fireproof board as the board surface. The cabinet door special for the motor home disclosed by the invention takes the PVC foam board as the board core and takes the fireproof board as the board surface, is light in weight and high in strength and has the fireproof, waterproof and heat-insulated functions, and the using standard of the motor home is met; and moreover, the cabinet door special for the motor home is simple in structure, portable, practical and capable of saving preparation materials and cost and has significance for promoting application and development of the motor home.

Owner:成都原景旅居科技有限公司

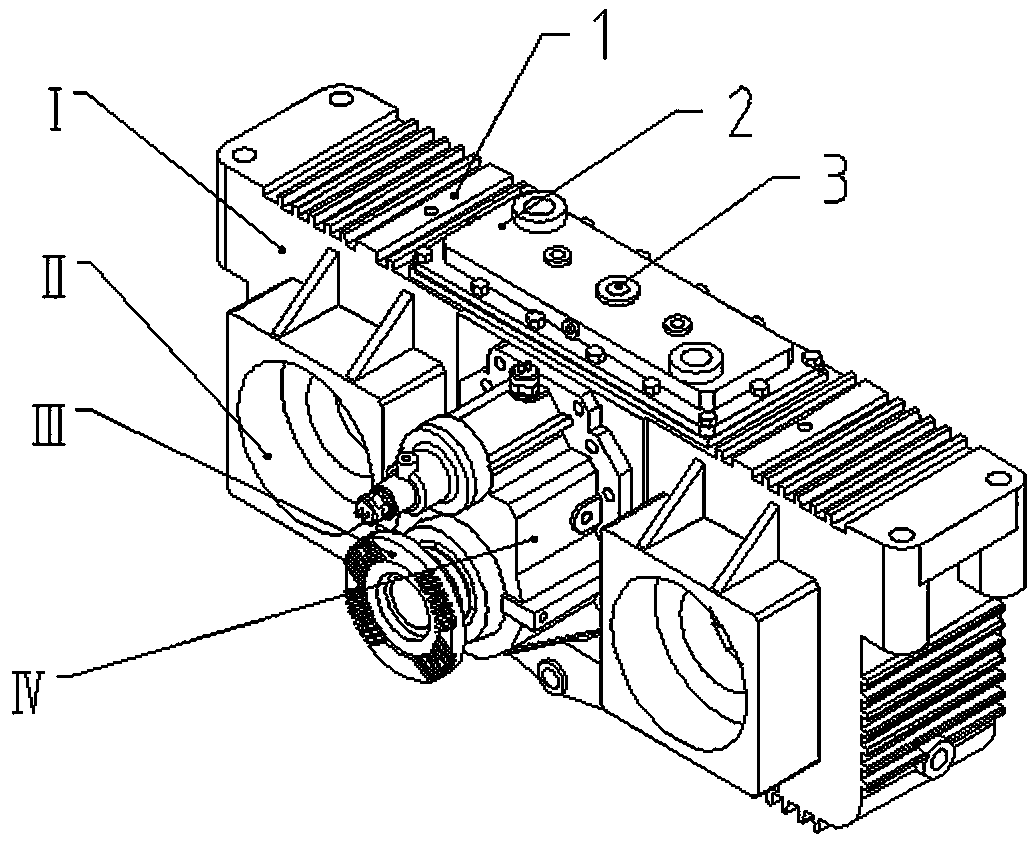

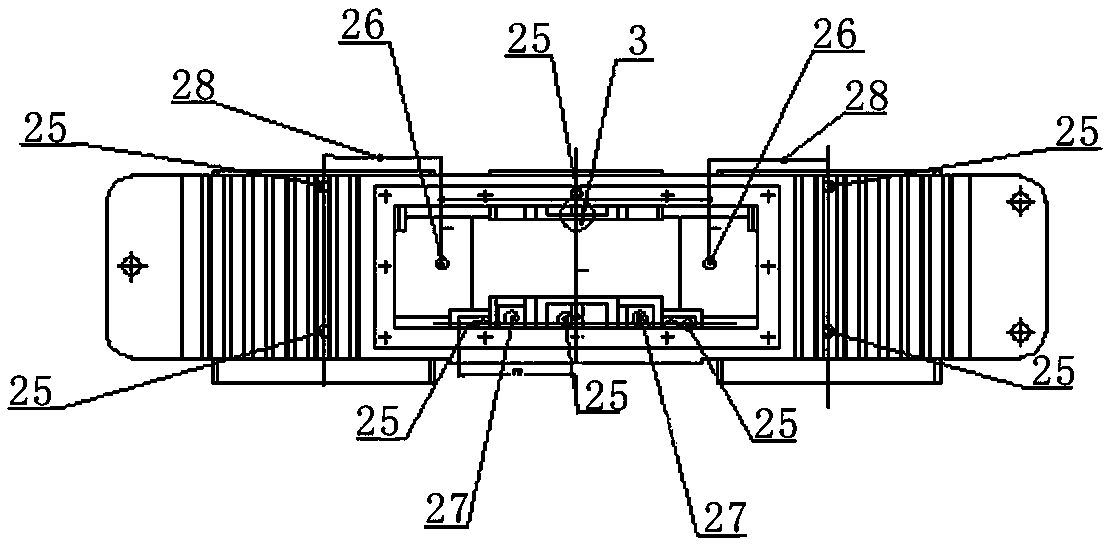

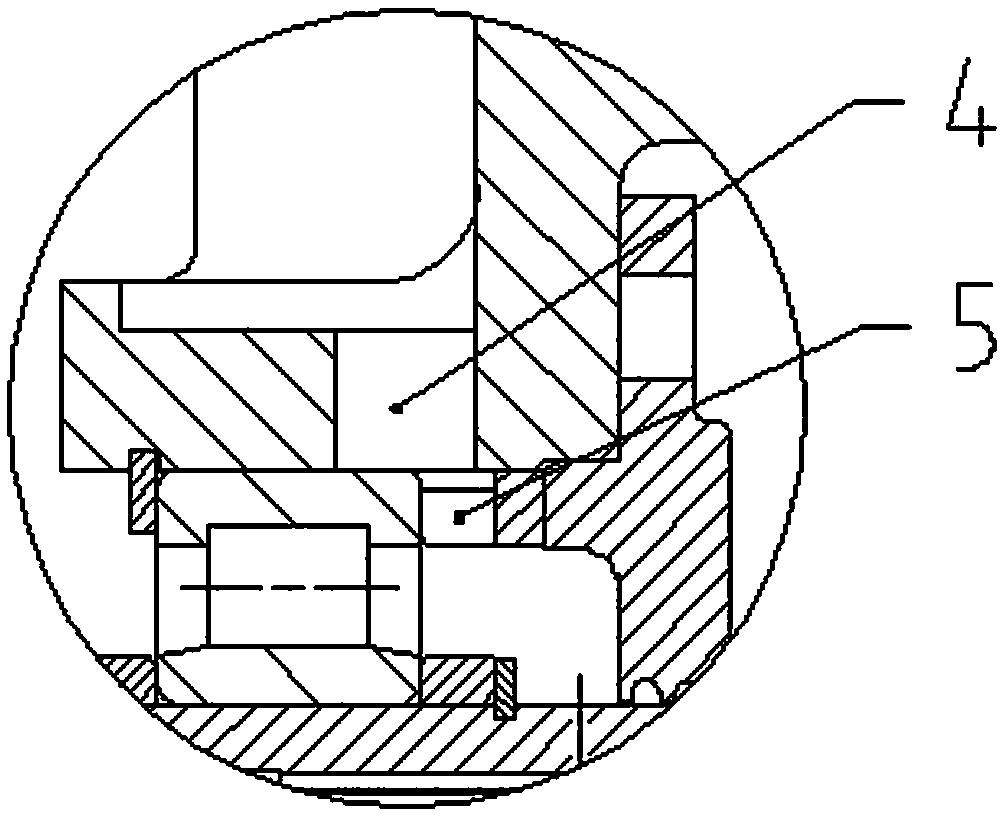

Gearbox applied to high-speed wheel excavator

InactiveCN108105366AImprove transition efficiencyFully lubricatedGear lubrication/coolingHydraulic motorGear drive

The invention relates to a gearbox applied to a high-speed wheel excavator. The gearbox comprises a box body part, an input part, an output part, a front axle part and a lubricating system and is characterized in that the lubricating system is located in the box body part, the input part is driven by four hydraulic motors, the input part and the output part are directly driven through gears, and the front axle part controls power output and interruption through a shifting fork; the lubricating system is combined by a forced lubricating system and splash lubricating system, the forced lubricating system comprises inner oil channels arranged in the box body and box cover of the box body part, the inner oil channels are connected with an external oil pump through a threaded hole, lubricatingoil is pumped into the inner oil channels, and the inner oil channels are communicated with a front axle support bearing, an input output support bearing, a shifting fork slide sleeve and a gear meshing point; splash lubricating is achieved through gear oil stirring and oil-collecting-groove guiding, and the splash lubricating system is communicated with a bearing through oil holes in a spacing ring to lubricate the bearing. The gearbox is simple in structure, capable of increasing the highest advancing speed of the wheel excavator, capable of increasing the transition efficiency of the wheelexcavator.

Owner:HANGZHOU ADVANCE GEARBOX GRP

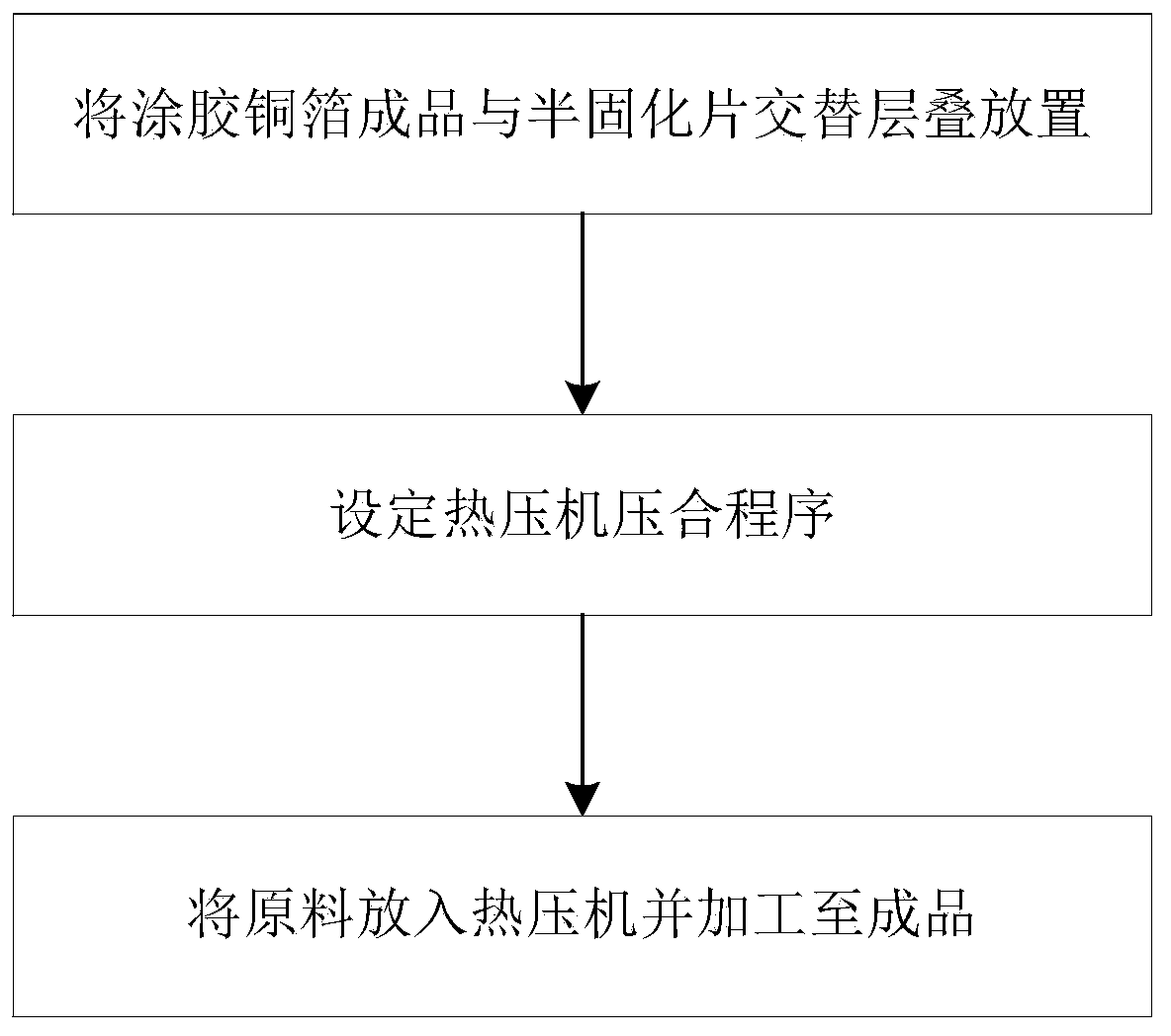

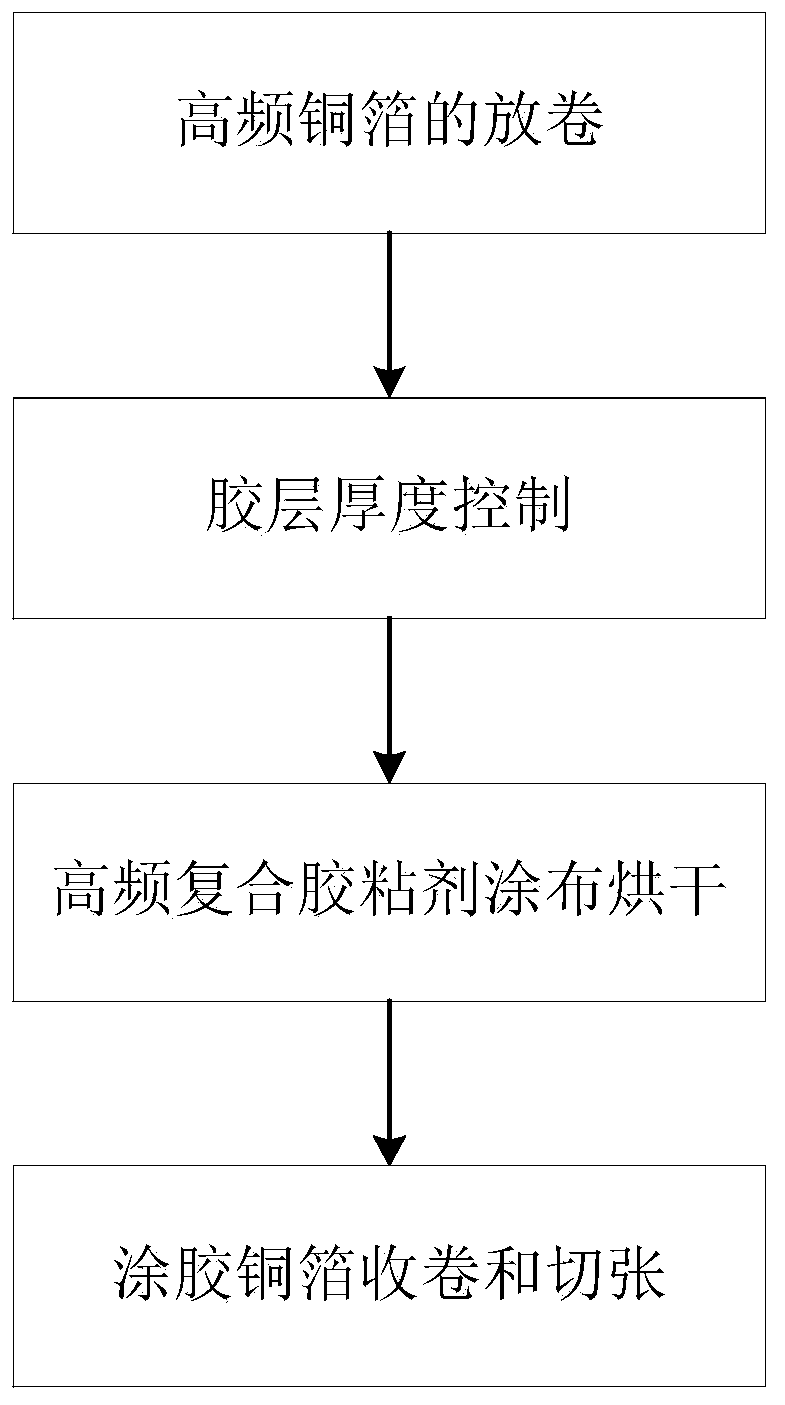

High-frequency copper-clad plate and preparation method thereof

InactiveCN111002651AImprove thermal conductivityExcellent dielectric propertiesLamination ancillary operationsLaminationRough surfaceCopper foil

The invention relates to a high-frequency copper-clad plate and a preparation method thereof, and aims to solve the problems of complex process and material pollution in the existing high-frequency copper-clad plate production process. The high-frequency copper-clad plate comprises gummed copper foils and prepregs, and the gummed copper foils and prepregs are sequentially and alternately stacked.The preparation method of the high-frequency copper-clad plate comprises the following steps; a steel plate, a bearing disc, an upper buffer pad and a lower buffer padare cleaned; the lower buffer padis placed in the middle of the bearing disc, and then the steel plate is placed on the lower buffer pad; the gummed copper foilwith the rough surface facing upwards is placed in the center of the steel plate and laid flatly; the prepregs and the glued copper foils are alternately laminated in sequence according to the set laminating number, then the upper buffer pads are placed in the centers ofthe prepregs and the glued copper foils, and steel covers cover the prepregs and the glued copper foils; a pressing program of a hot press is set; the materials are fed into the hot press; and the hotpressis started, and processing is performed to obtain the high-frequency copper-clad plate finished product by the hot press through vacuum, heating and hydraulic processes according to set parameters.

Owner:陕西卫宁电子材料有限公司

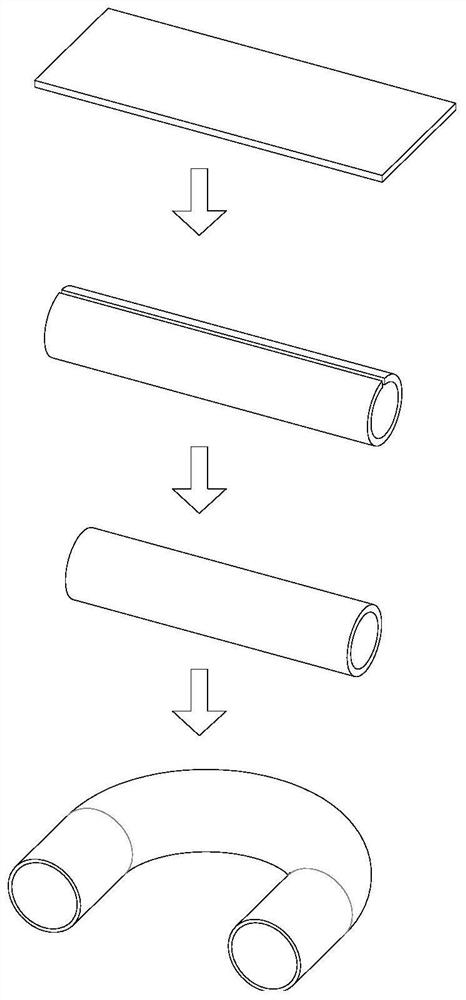

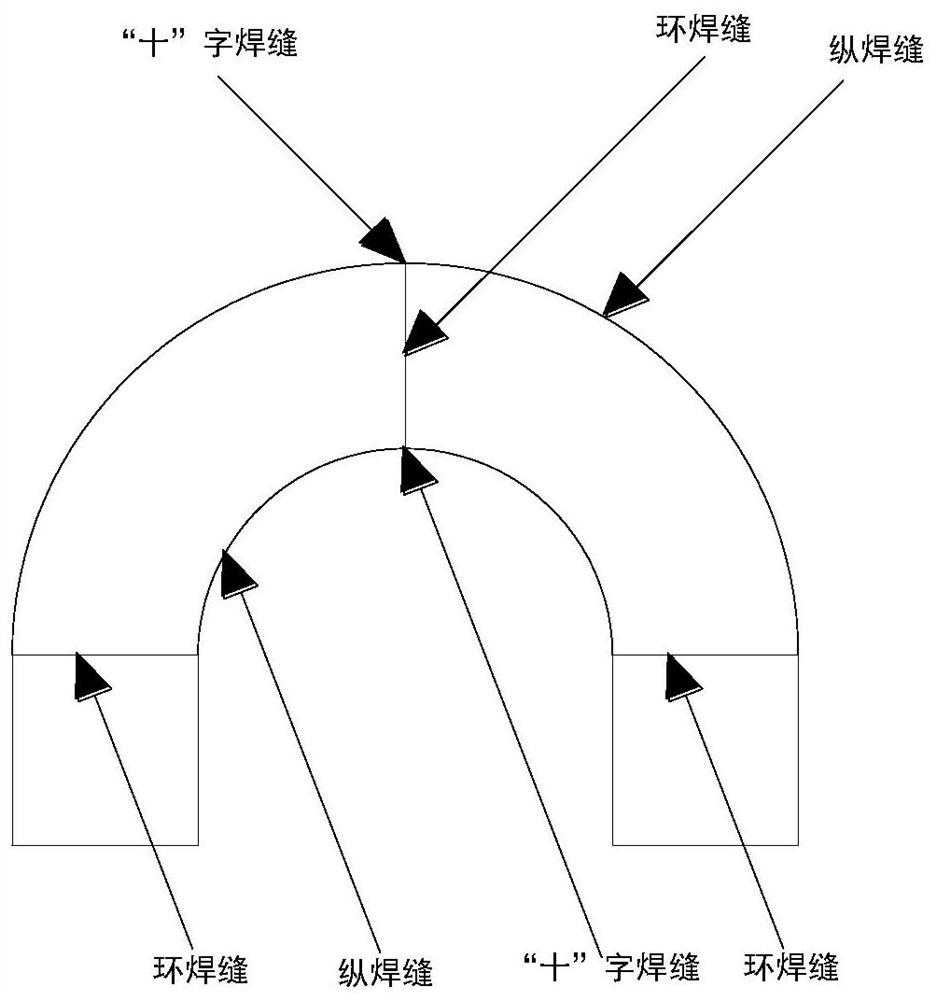

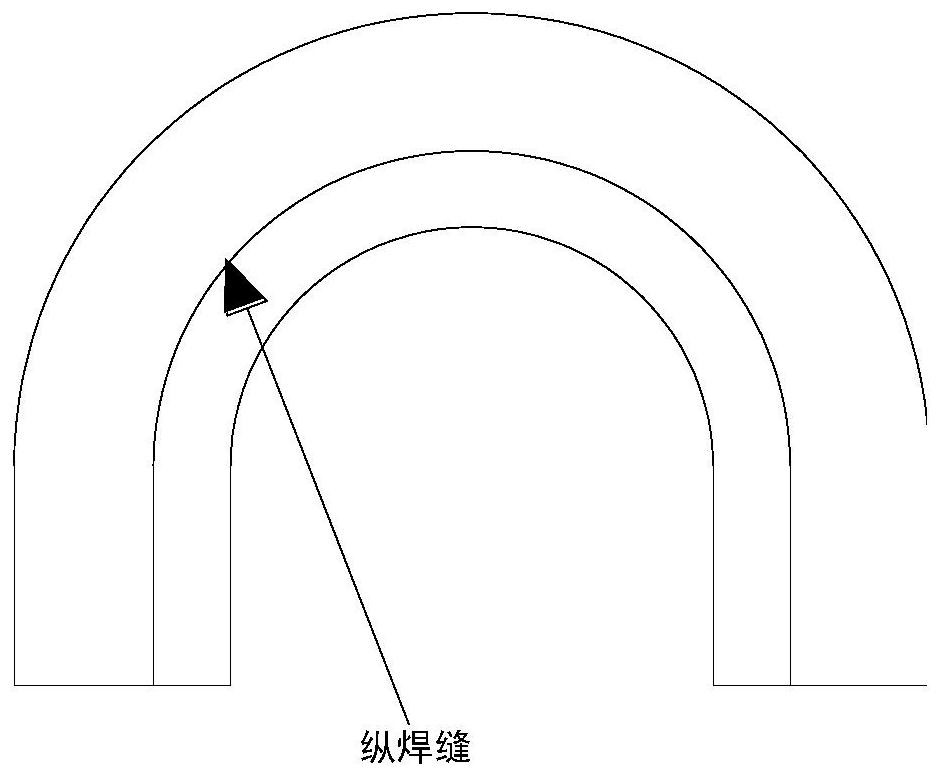

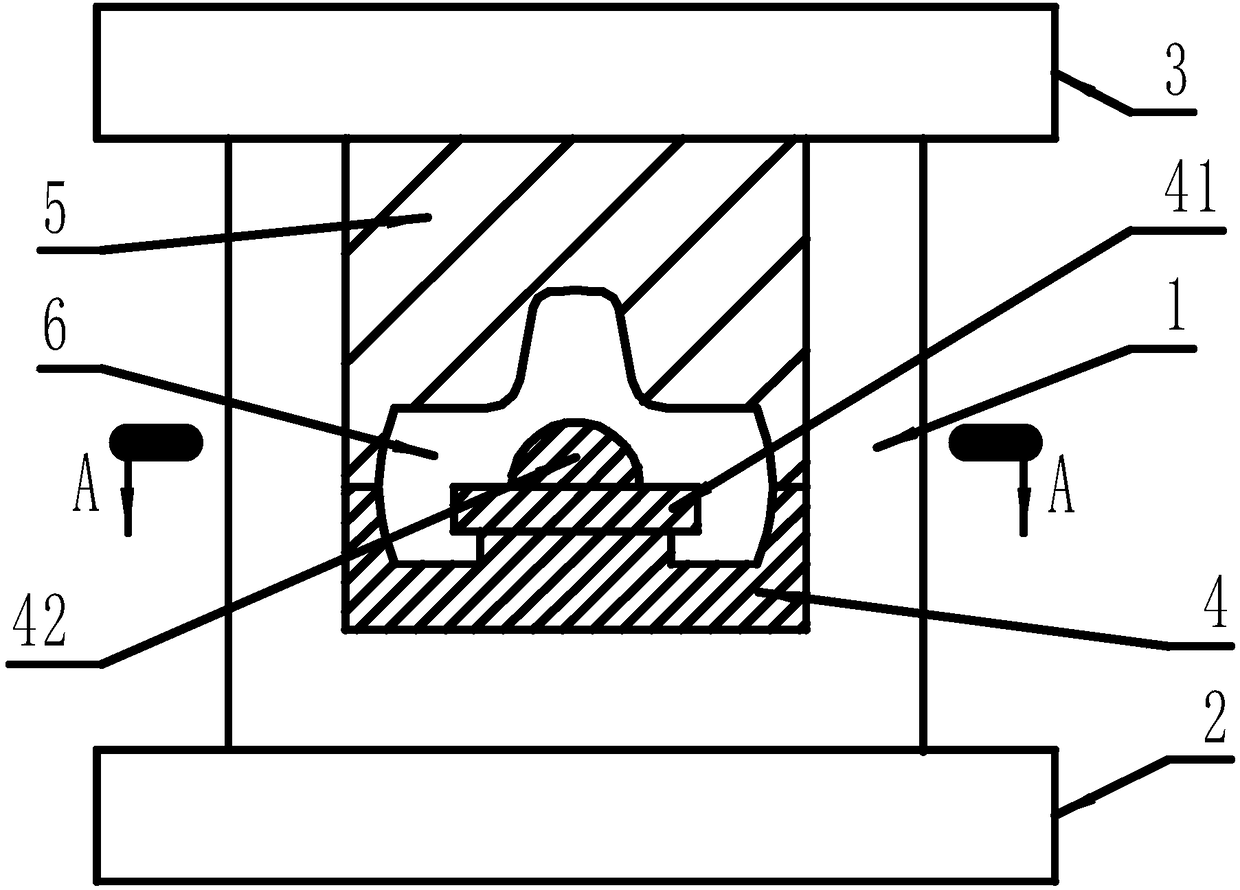

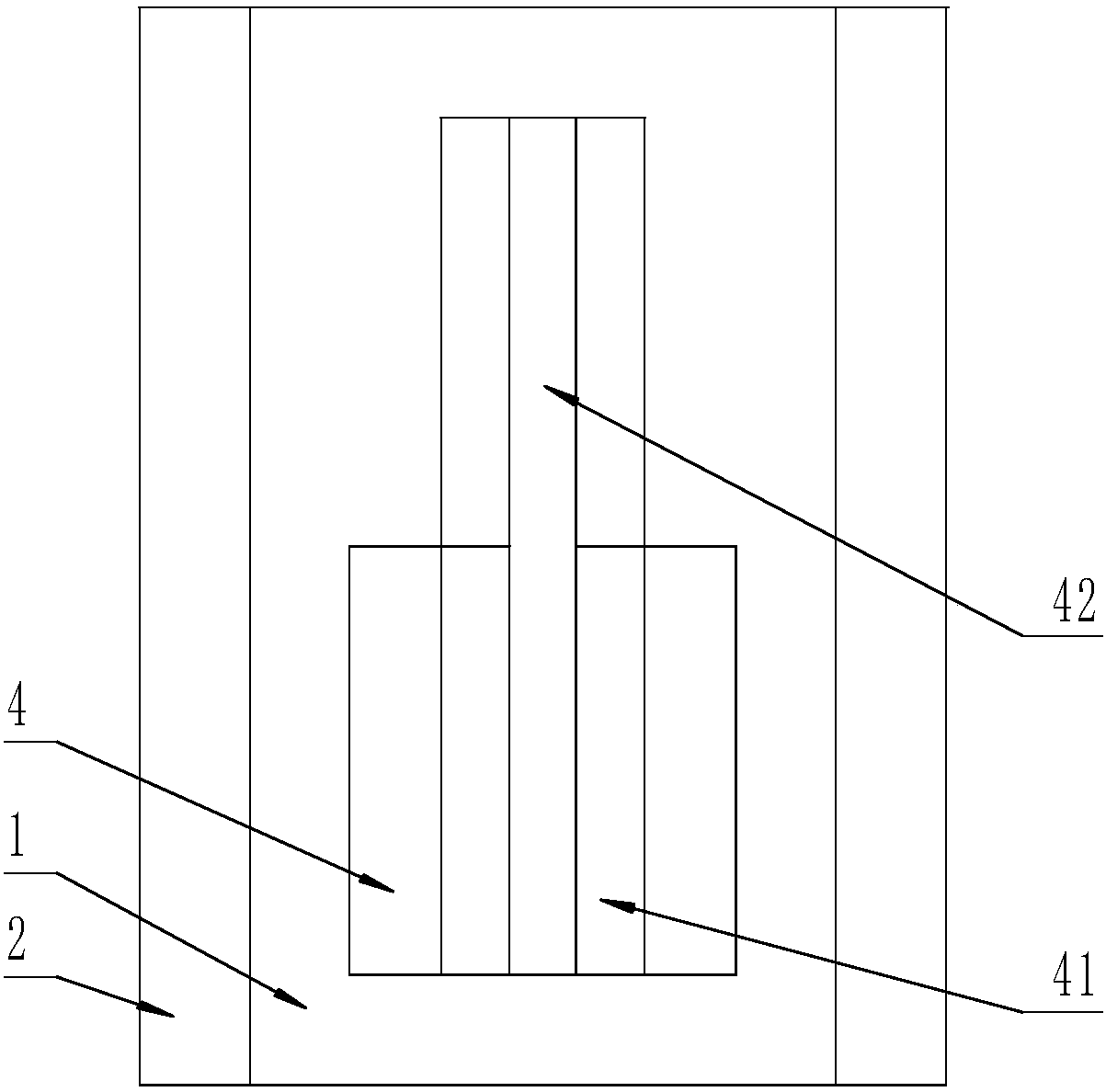

Large-diameter one-time-formed 180-degree elbow and machining process thereof

InactiveCN113090844AMeet the use standardFreely adjust the bending radiusSiphonsBendsButt jointPipe fitting

The invention relates to the technical field of elbows, in particular to a large-diameter one-time-formed 180-degree elbow, which comprises an elbow body provided with a longitudinal welding seam in the extending direction of the elbow body. A machining process of the large-diameter one-time-formed 180-degree elbow comprises the following steps that step 1, a rectangular steel plate is selected and used, the rectangular steel plate is rolled into a cylinder shape, and a cylinder is manufactured; step 2, the butt joint faces of the cylinders in the first step are welded, and a base metal pipe fitting is obtained; and step 3, a hot-bending pipe bending machine is adopted for carrying out hot forming on the base material pipe fitting in the second step, the base material pipe fitting is machined to have the needed bending degree, no cross-shaped welding seam is contained, only longitudinal welding seams are contained, one-time forming is achieved, and the pressure bearing capacity is improved.

Owner:沧州伟浩管道科技有限公司

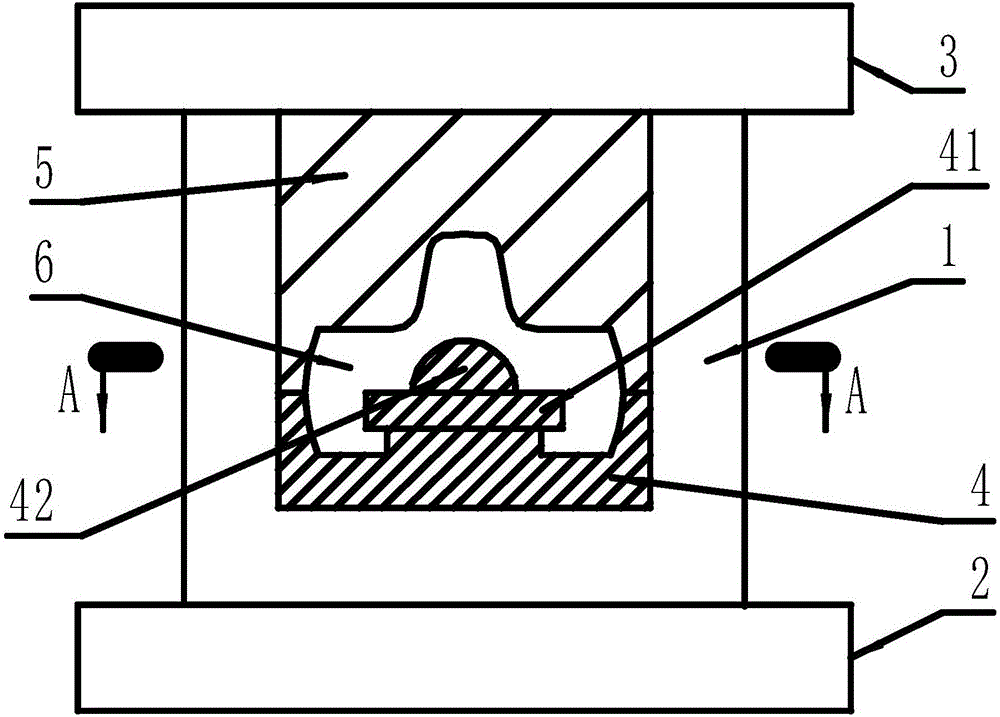

A preparation process of ultra-high molecular weight polyethylene sucker rod centralizer

InactiveCN106084430BImprove material performanceEasy to processDrilling rodsDrilling casingsPolymer scienceGraphite

The invention provides a producing process of a sucker rod centralizer made of ultrahigh-molecular-weight polyethylene. A filler is prepared from the following components by weight: 1% to 1.5% of graphite, 1.5% to 2% of carbon black, 1% to 1.5% of calcium stearate, 0.4% to 1% of pyrogenic silica, 1% to 2% of titanium dioxide, 0.5% to 1% of a coupling agent vinyl siloxane, and 90% to 95% of ultrahigh-molecular-weight polyethylene, wherein the total percentage by weight of the components is 100%. The producing process comprises the following steps: pouring the filler into the upper part of a lower sucker rod centralizer die, carrying out die assembly, putting assembled dies into a press machine for pressing to obtain a blank, and starting to heat to ensure that the filter is heated and melts into liquid gradually; filling a sucker rod centralizer die cavity with the liquid filler, continuing heating and pressing till a product is shaped, carrying out pressure-maintaining cooling, opening dies, and taking out of a finished product. According to the producing process, the material performance and the processing manner of ultrahigh-molecular-weight polyethylene are improved, so that the improved ultrahigh-molecular-weight polyethylene can be used for producing the sucker rod centralizer, and the sucker rod centralizer made of the improved ultrahigh-molecular-weight polyethylene material has higher chemical corrosion resistance, abrasion resistance and impact resistance, and longer service life.

Owner:LUOYANG GUORUN NEW MATERIAL TECH CO LTD

A kind of frost-resistant hard epoxy asphalt pavement material and preparation method thereof

InactiveCN103773037BImprove frost resistanceHigh hardnessBuilding insulationsPolymer scienceRoad surface

The invention relates to an antifreeze hard epoxy asphalt pavement material and a preparation method thereof. The antifreeze hard epoxy asphalt pavement material is composed of the following components according to the weight ratio: 28-30 parts of petroleum asphalt, calcium stearate 5-9 parts for vinyl epoxy resin, 18-22 parts for vinyl epoxy resin, 9-13 parts for trimellitic anhydride, 5-6 parts for butyric acid, 4-6 parts for 1-hexene, and 3-5 parts for magnesium chloride. The pavement material is prepared by heating, melting, stirring, pulverizing, heat preservation and other steps of each material component. The prepared pavement material has good frost resistance and high hardness, which can prevent cracking due to cold weather as a road material. phenomenon occurs.

Owner:NANTONG SOUTHEAST HIGHWAY ENG

Cloth cutting machine for garment processing

ActiveCN107630346BQuick releaseAvoid economic wasteSevering textilesMetal working apparatusPulp and paper industryMaterial resources

The invention discloses a cloth cutting machine for clothes processing. The cloth cutting machine comprises a processing platform, wherein a stainless steel plate is arranged at the top of the processing platform and a cloth cutting frame is arranged at one side of the top of the stainless steel plate; a material guide device is arranged at one side of the cloth cutting frame; a first electric retractable rod penetrates through the top of the cloth cutting frame; a supporting plate is arranged at the bottom end of the first electric retractable rod; a cutter is arranged at the bottom of the supporting plate; a fixing device is arranged at one side of the cutter; a clamping device is arranged at the other side of the cutter; guide rods are arranged at two sides of the supporting plate; thecloth cutting machine relates to the technical field of the clothes processing. The cloth cutting machine for the clothes processing can be used for rapidly detaching the cutter; heating wires are arranged at two sides of a cutter groove so that unnecessary economic wastes are avoided and the manpower and material resources are saved; the height and the width of a friction wheel can be adjusted sothat the cloth cutting machine is suitable for cloth with any specification; a condition that the cloth has folds in a cloth cutting process is prevented; the cloth cutting effect of the cloth cutting machine is ensured and the utilization standards of users can be met.

Owner:沈丘县永盛服饰有限公司

Producing process of sucker rod centralizer made of ultrahigh-molecular-weight polyethylene

InactiveCN106084430AImprove material performanceEasy to processDrilling rodsDrilling casingsGraphiteChemical corrosion

The invention provides a producing process of a sucker rod centralizer made of ultrahigh-molecular-weight polyethylene. A filler is prepared from the following components by weight: 1% to 1.5% of graphite, 1.5% to 2% of carbon black, 1% to 1.5% of calcium stearate, 0.4% to 1% of pyrogenic silica, 1% to 2% of titanium dioxide, 0.5% to 1% of a coupling agent vinyl siloxane, and 90% to 95% of ultrahigh-molecular-weight polyethylene, wherein the total percentage by weight of the components is 100%. The producing process comprises the following steps: pouring the filler into the upper part of a lower sucker rod centralizer die, carrying out die assembly, putting assembled dies into a press machine for pressing to obtain a blank, and starting to heat to ensure that the filter is heated and melts into liquid gradually; filling a sucker rod centralizer die cavity with the liquid filler, continuing heating and pressing till a product is shaped, carrying out pressure-maintaining cooling, opening dies, and taking out of a finished product. According to the producing process, the material performance and the processing manner of ultrahigh-molecular-weight polyethylene are improved, so that the improved ultrahigh-molecular-weight polyethylene can be used for producing the sucker rod centralizer, and the sucker rod centralizer made of the improved ultrahigh-molecular-weight polyethylene material has higher chemical corrosion resistance, abrasion resistance and impact resistance, and longer service life.

Owner:LUOYANG GUORUN NEW MATERIAL TECH CO LTD

Toilet wallboard special for motor homes

InactiveCN106240113AGood effectEffectively removes odorsSynthetic resin layered productsVehicle sanitationActivated carbonMotor home

The invention relates to the technical field of motor homes, in particular to a toilet wallboard special for motor homes. The toilet wallboard special for motor homes comprises a first fireproof board layer, a PVC foam board layer, a second fireproof board layer, an active carbon filled layer and a breathing layer which are arranged in sequence from left to right. The active carbon filled layer contains spherical active carbon, the particle size of spherical active carbon is 10-50 micrometers, and the surface of spherical active carbon is grafted with titanium dioxide. According to the toilet wallboard special for motor homes, by filling the active carbon filled layer with active carbon grafted with titanium dioxide, the wallboard can continuously and effectively remove peculiar smells in a toilet through the breathing layer, use is convenient, and the structure is simple; the PVC foam board and the fireproof boards are adopted as main materials, the mass is small, the strength is high, the fireproof, waterproof and heat-insulating functions are achieved, and the motor home use standard is met; besides, the toilet wallboard special for motor homes is simple in structure, light, practical and capable of saving preparation materials and reducing preparation cost and has great significance in promoting application and development of motor homes.

Owner:成都原景旅居科技有限公司

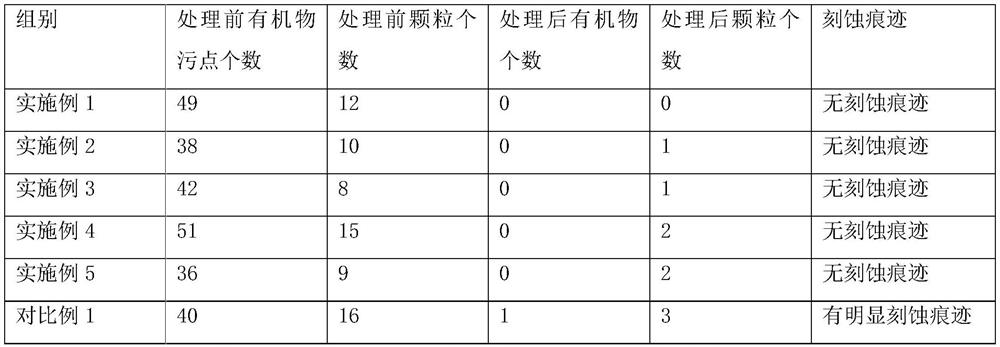

Strong oxidant cleaning solution for wafer boat for semiconductor production and cleaning method thereof

PendingCN113637536ALow costImprove cleaning efficiencySemiconductor/solid-state device manufacturingInorganic non-surface-active detergent compositionsEnvironmental chemistryPotassium chlorate

The invention discloses a strong oxidant cleaning solution for a wafer boat for semiconductor production, the strong oxidant cleaning solution is a mixed solution of hydrofluoric acid and a strong oxidant, and the strong oxidant is at least one of potassium dichromate, potassium permanganate, potassium perchlorate and sodium ferrate; the concentration of hydrofluoric acid is 2-20wt%, and the concentration of the strong oxidant is 1-10wt%. The mixed solution of hydrofluoric acid and the strong oxidant is used for cleaning the semiconductor wafer boat, and nitrogen is used for bubbling, so that pollution can be completely removed, and the cleanliness of the product is ensured. The wafer boat cleaned by the method is low in cost and high in cleaning efficiency; rainbow prints on the surface of the wafer boat and organic pollutants and inorganic particulate matters such as stubborn photoresist can be effectively removed. Meanwhile, the surface of the wafer boat can be ensured to be clean and free of corrosion marks to the greatest extent, and the product is ensured to meet the use standard.

Owner:江苏凯威特斯半导体科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com