Novel sheet metal cutting machine

A metal sheet and cutting machine technology, which is applied to metal processing machinery parts, metal processing equipment, large fixed members, etc., can solve the problems of complex cutting process, unsafe metal sheet, difficult manual operation, etc., and achieve simple cutting process, High cutting efficiency and easy manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

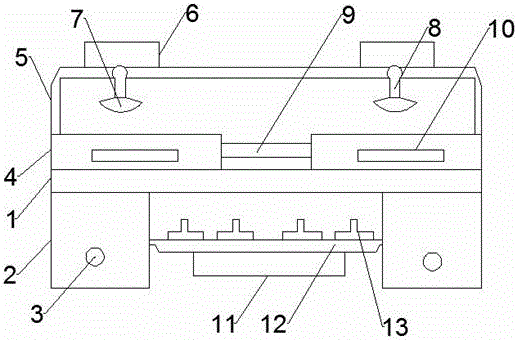

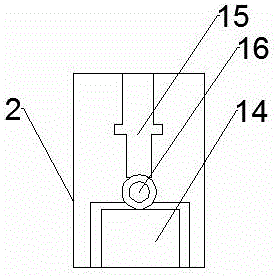

[0017] see figure 1 , figure 2 and image 3 , the present invention provides a technical solution: a novel sheet metal cutting machine, comprising a load-bearing plate 1, two support legs 2 fixed on the lower end of the load-bearing plate 1, and two cutting tables 3 installed on the upper end of the load-bearing plate 1, The No. 3 driver 14 is installed in the two support legs 2, and the No. 3 driver 14 is connected with an electric control lifting rod 15 through a speed governor 16. The top of the electric control lifting rod 15 passes through the load-bearing plate 1 and is connected to the cutting table 4. Control the height of the cutting table 4 and the angle of cutting the sheet metal. A knob 3 is installed on the support leg 2. The knob 3 is electrically connected to the governor 16. The upper ends of the two cutting tables 4 are connected by a fixed frame 5, fixed Two No. 1 drivers 6 are installed on the top of the frame 5, and the bottom of the No. 1 driver 6 is co...

Embodiment 2

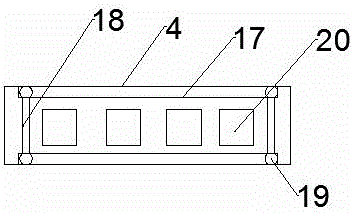

[0019] see figure 1 , figure 2 and image 3 , the present invention provides another technical solution: limit the position of the metal plate placed on the cutting table 4 by a limit rod 18, rotate the knob 3, control the governor 16 to adjust the speed, and the second driver 14 drives the motor Control the lifting rod 15 to lift, thereby the height of the cutting table 4 is adjusted, the expansion and contraction of the telescopic device 8 can be controlled by the No. 1 driver 6, and the cutting tool 7 can quickly cut the metal sheet, which can be cut in two A metal plate or a metal plate is placed on the platform 4, and the two supporting legs 2 are connected by a fixed plate 12. Four grinders 13 are installed on the upper end of the fixed plate 12, and the second driver 11 is fixed on the lower end of the fixed plate 12. , the grinder 13 is electrically connected to the No. 2 driver 11, and the No. 2 driver 11 can drive the grinder 13 to work, and can grind the cut meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com