Half-slice-laminated solar assembly and preparation method thereof

A technology for solar modules and laminated modules, applied in the manufacturing of semiconductor devices, electrical components, and final products, etc., which can solve the problems of low effective area utilization and conversion rate of modules, inability to break size constraints and design specifications, and rigid and outdated dimensions. , to achieve the effect of improving light utilization, improving area utilization rate and conversion rate, and stable welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

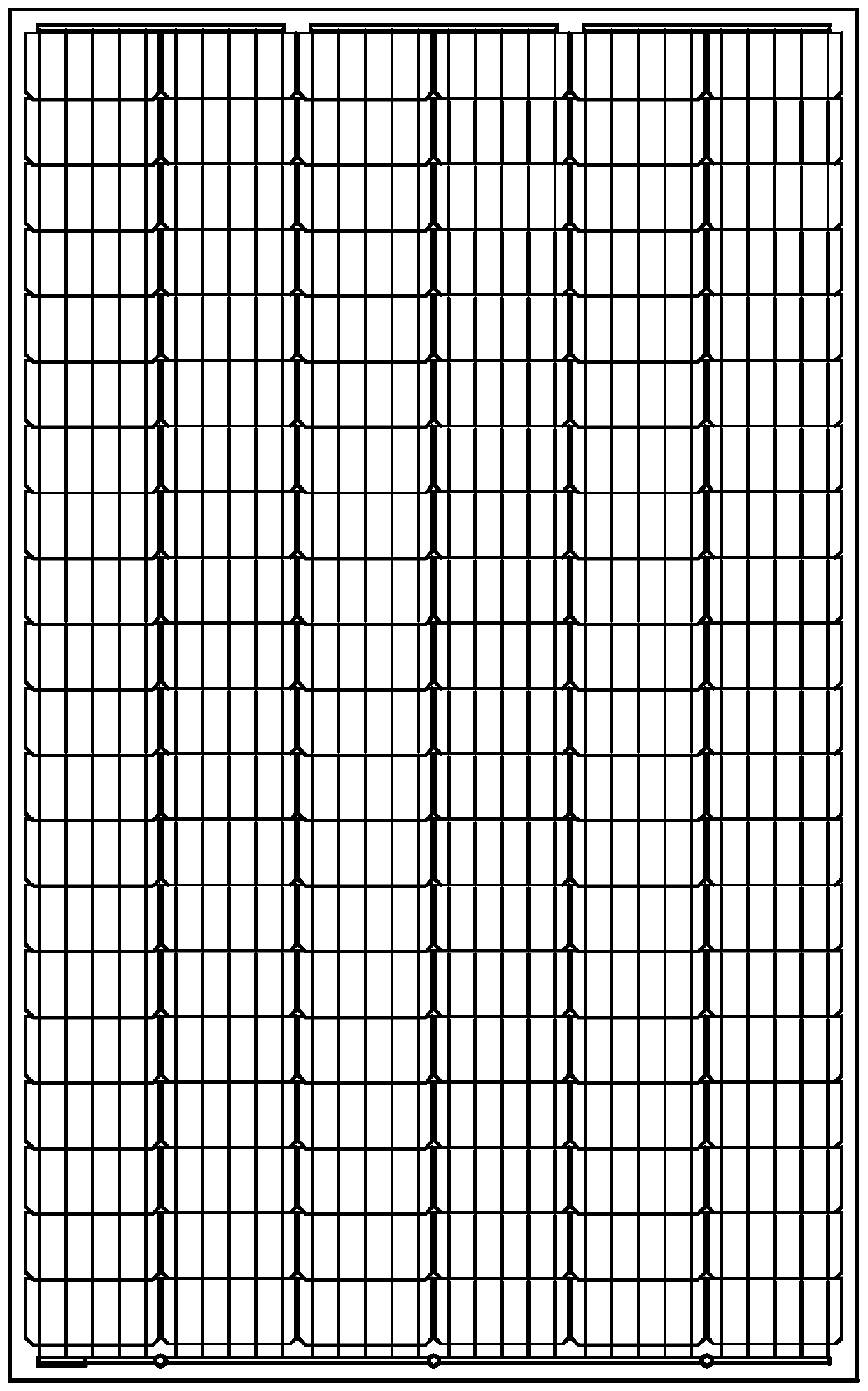

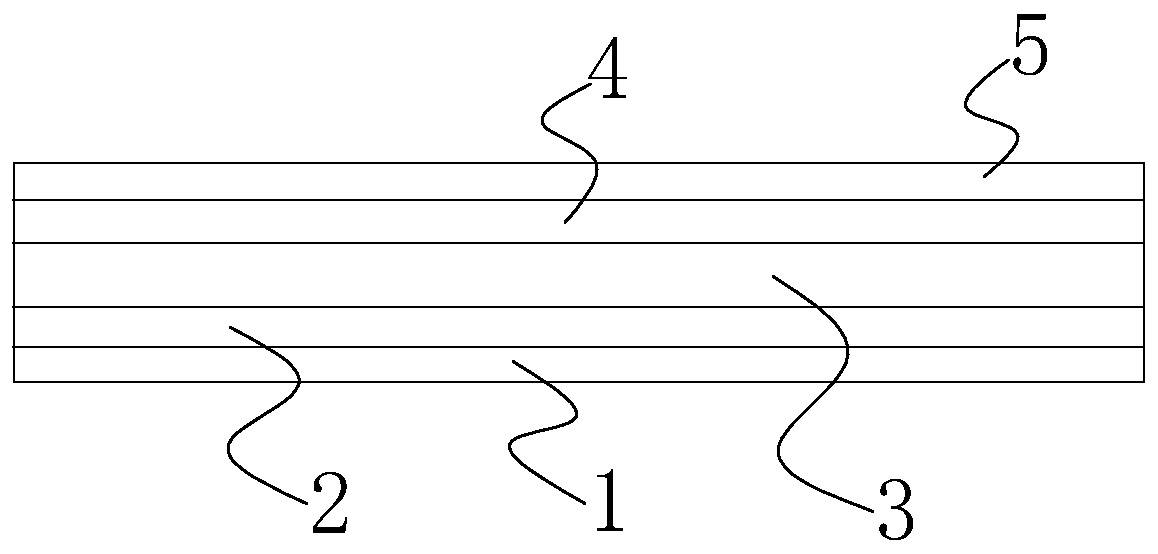

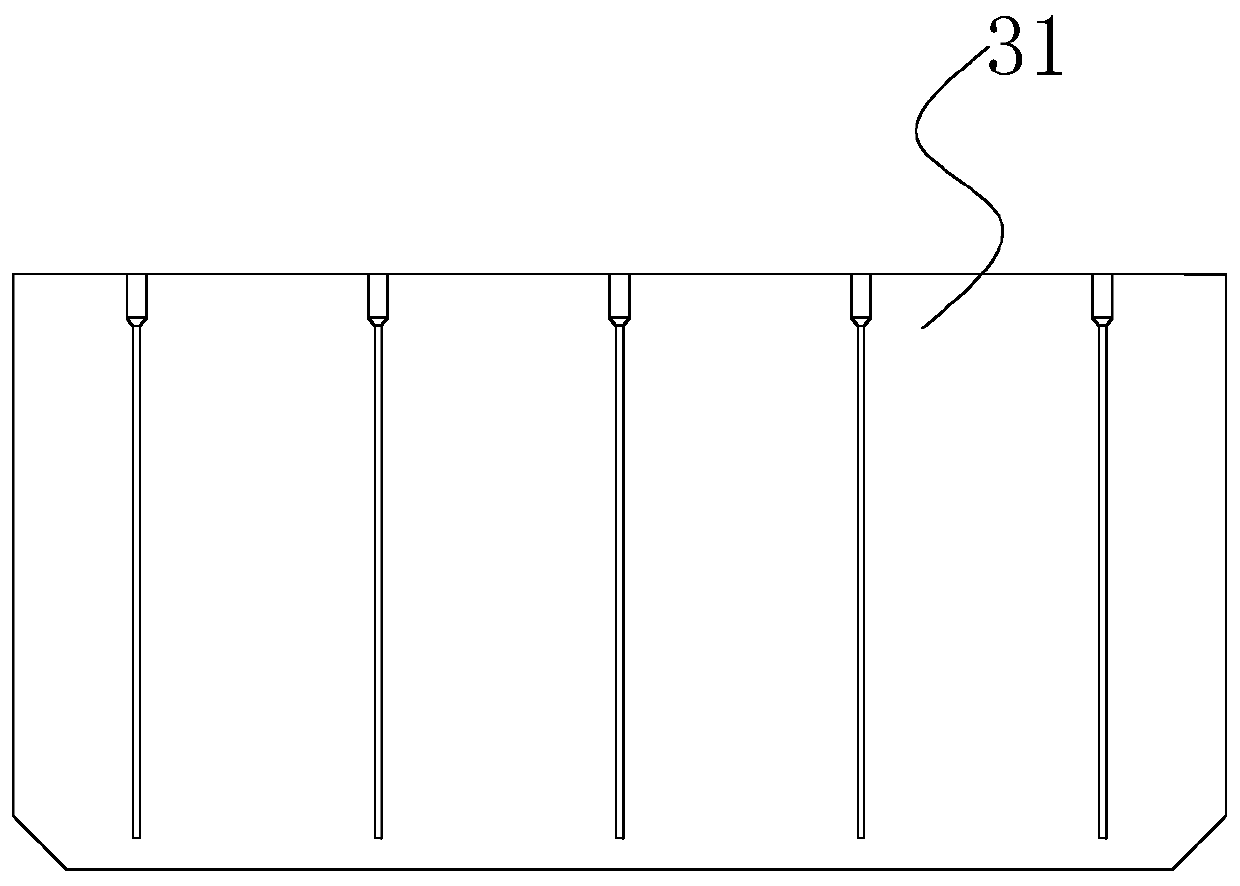

[0040] Such as figure 1 with figure 2 As shown, this embodiment discloses a half-sheet laminated solar module and its preparation method. The half-sheet laminated solar module sequentially includes a tempered glass layer, a first adhesive film layer, a battery string component layer, and a second adhesive film layer from bottom to top. and a back plate material layer, the battery string assembly is obtained by arranging a plurality of battery strings according to the assembly pattern, and each battery string includes a plurality of sliced batteries that are welded in an overlapping arrangement by welding strips.

[0041] A method for preparing a half-sheet laminated solar module, comprising the following steps:

[0042] S1. Slice the battery sheet to obtain a sliced battery, and use laser to insulate the cutting edge;

[0043] Further, the method in step S1 specifically includes:

[0044] S11, positioning the battery sheet for the camera;

[0045] S12. Adsorbing the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com