Production process and device for machining PE double-wall corrugated pipe with socket and spigot on line

A double-wall corrugated pipe and production process technology, which is applied to the production technology field of PE double-wall corrugated pipes, can solve the problems of waste of transition parts, and achieve the effect of reducing workload and simplifying cutting process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0022] In the description of the present invention, the terms "front end" and the like are only for convenience of description and definition, and should not be construed as limiting the present invention.

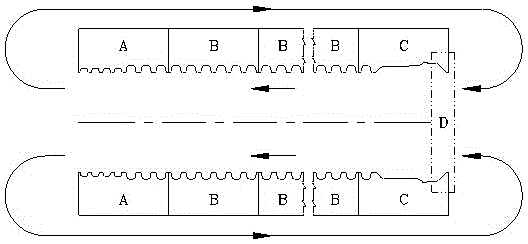

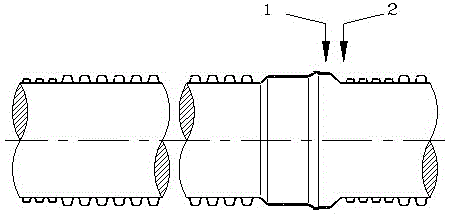

[0023] The forming of PE double-wall corrugated pipe is mainly completed by the corrugated pipe forming machine. Its basic structure is a group of forming modules installed on a cyclically movable track to realize the forming of the pipe. Its working principle and forming method are industry-leading well known to personnel.

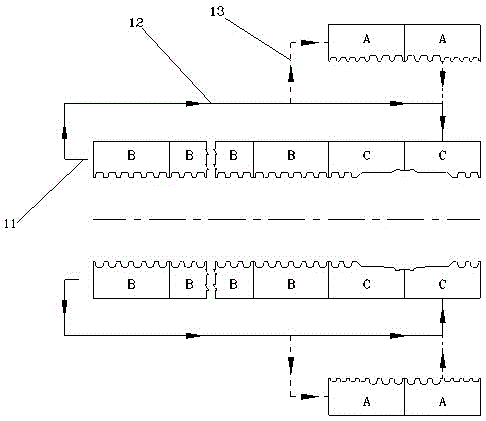

[0024] see image 3 , the forming module installed on the bellows forming machine is set on the circulating track.

[0025] The forming modules include a straight pipe module B, a symmetrical socket module group AA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com