A kind of sludge modifier and the method for forming roadbed soil from modified sludge

A modifier and roadbed soil technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve problems such as pollution risks, water pollution, odor, etc., and achieve resource utilization , Excellent mechanical properties, simple modification method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]

[0026] The sludge modifier is formed by reacting the above-mentioned oxides at a high temperature of 1200°C.

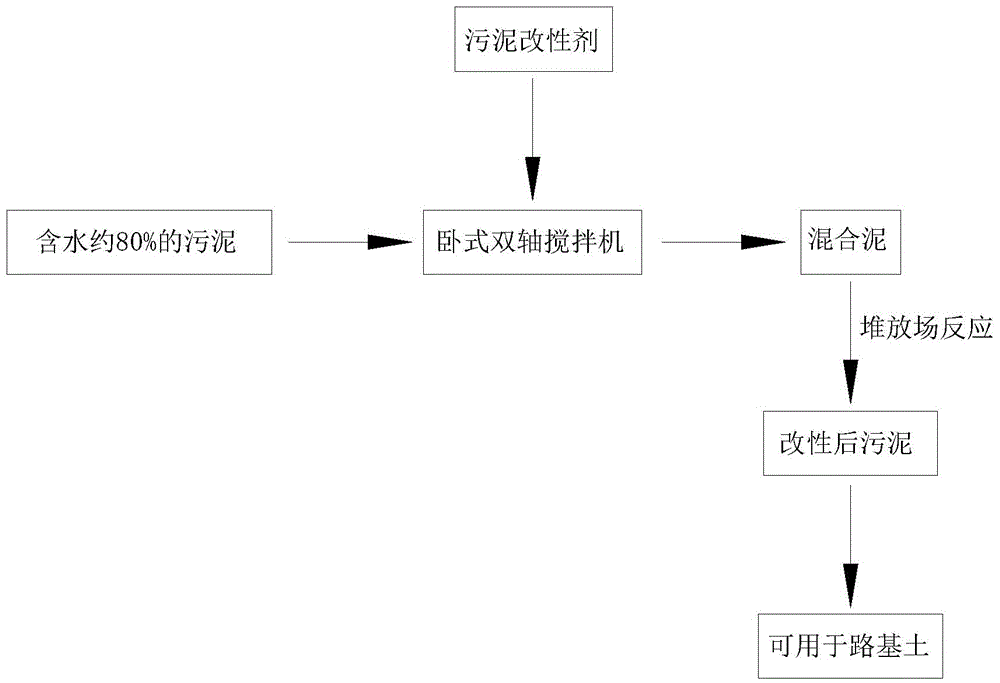

[0027] The sludge modifier and sludge generated by the above reaction are mixed in a horizontal double-shaft mixer at a ratio of 1:5, and the mixed sludge is formed at the same time, and the mixed sludge is stacked for physical and chemical reaction. To transform into stable subgrade soil, and to meet the requirements of subgrade soil, that is, to meet the requirements of ordinary cohesive soil, the content of particles with a plasticity index>10 and a particle size larger than 0.075mm does not exceed 50% of the total mass.

[0028] After testing, other index parameters of the modified sludge in Example 1 are shown in Table 1.

[0029] Because within the range of adding the sludge modifier according to the present invention, with the increase of the added amount of the sludge modifier, the reaction is more complete, and the indicators of the converted subg...

Embodiment 2

[0043]

[0044] The sludge modifier is formed by reacting the above-mentioned oxides at a high temperature of 1200°C.

[0045] The sludge modifier and sludge generated by the above reaction are mixed in a horizontal double-shaft mixer at a ratio of 1:5, and the mixed sludge is formed at the same time, and the mixed sludge is stacked for physical and chemical reaction. It is transformed into a stable subgrade soil, which meets the requirements of ordinary cohesive soil, and the content of particles with a plasticity index>10 and a particle size larger than 0.075mm does not exceed 50% of the total mass.

Embodiment 3

[0047]

[0048] The sludge modifier is formed by reacting the above-mentioned oxides at a high temperature of 1200°C. The sludge modifier and sludge generated by the above reaction are mixed in a horizontal double-shaft mixer at a ratio of 1:5, and the mixed sludge is formed at the same time, and the mixed sludge is stacked for physical and chemical reaction. It is transformed into a stable subgrade soil, which meets the requirements of ordinary cohesive soil, and the content of particles with a plasticity index>10 and a particle size larger than 0.075mm does not exceed 50% of the total mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com