Gearbox applied to high-speed wheel excavator

A technology for excavators and gearboxes, which is applied in the field of gearboxes and can solve problems such as the inability to meet the lubrication requirements of key parts, affecting user operations, and reducing the stability of gear meshing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

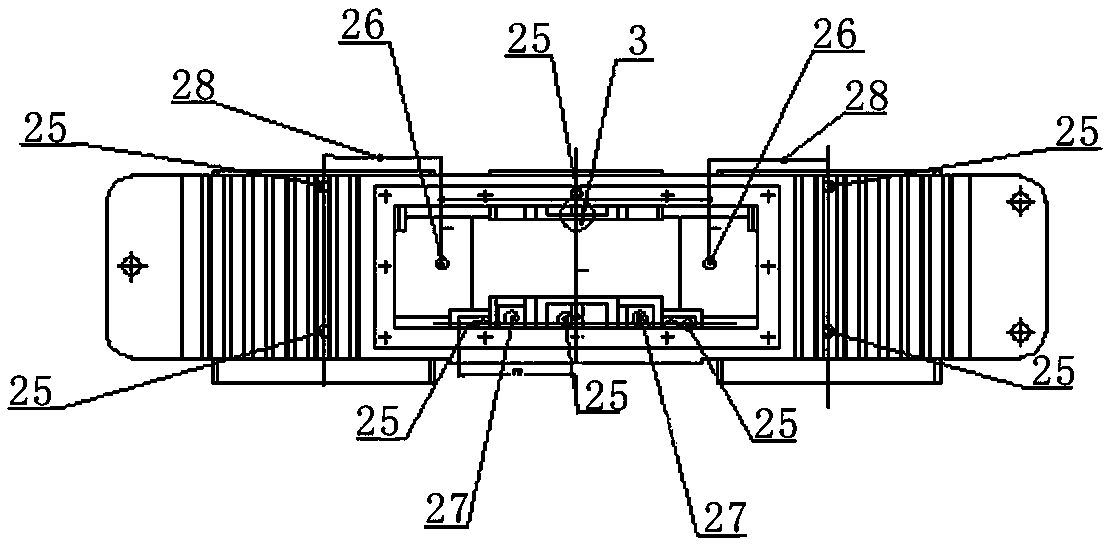

[0026] Example: figure 2 , 3 As shown, the lubrication system of the present invention uses a combination of forced lubrication system and splash lubrication to replace the traditional single splash lubrication.

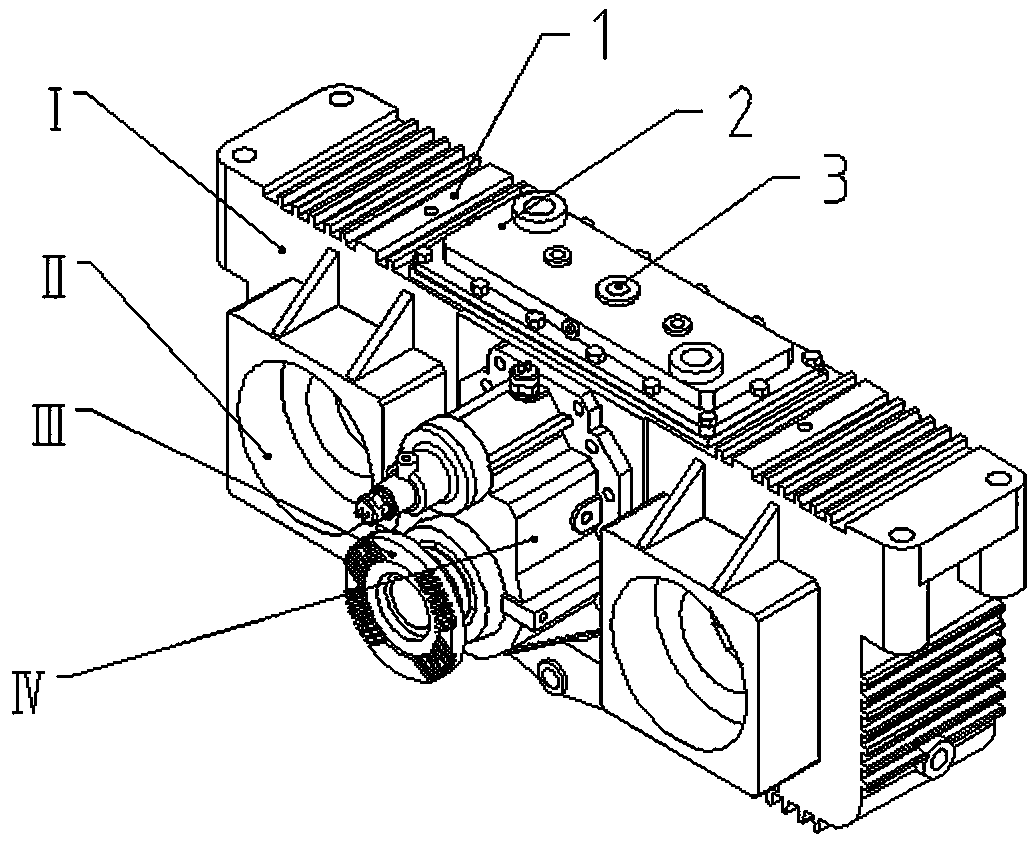

[0027] The forced lubrication system, such as figure 1 , 2 As shown in Fig. 1, make internal oil passages on the box body 1 and box cover 2 respectively, pump lubricating oil from threaded hole 3, and lubricate key parts such as front axle support bearings, input and output support bearings, shift fork sliding sleeves, and gear meshing points. ,Such as figure 2 shown.

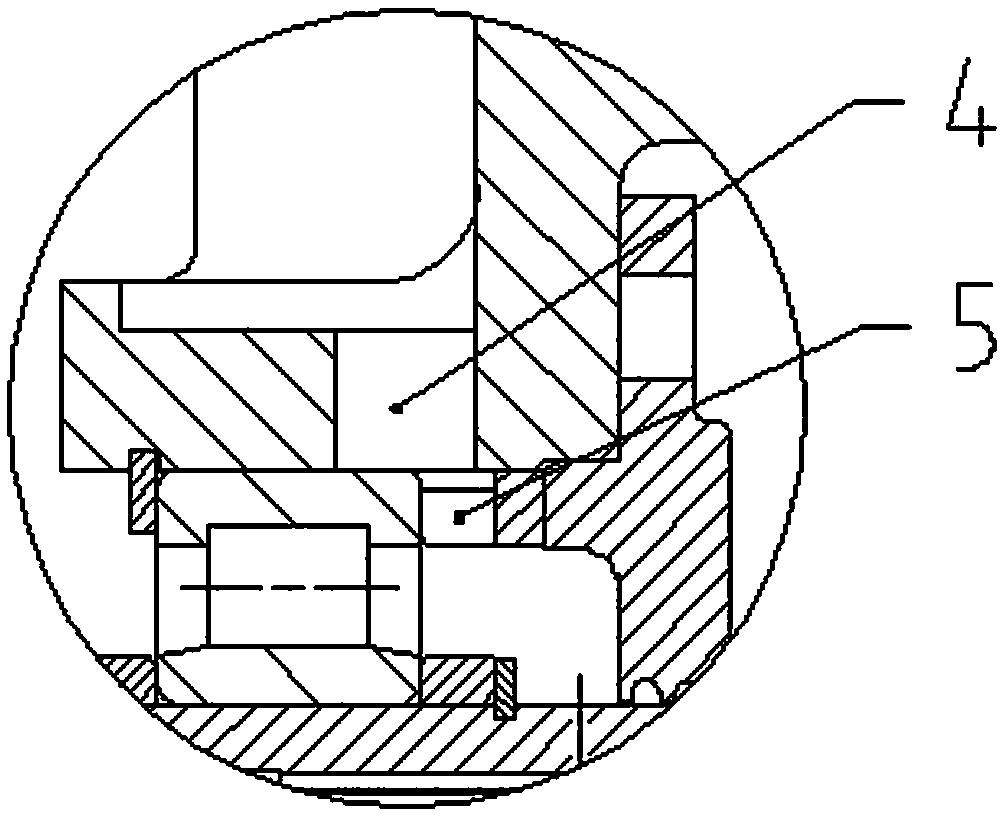

[0028] Said splash lubrication is achieved by stirring the oil through the gears and guiding it with the oil sump 4, such as image 3 As shown, the bearing is lubricated through spacer 5.

[0029] The spacer ring 5 is provided with an oil hole, which has the function of throttling while lubricating the bearing, preventing too much lubricating oil from trapping oil, and causing the inability to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com