Medical miniature brushless motor

A brushless motor, micro technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of reduced production efficiency, limited shock absorption effect, complicated operation, etc., to achieve extended service life, good shock absorption effect, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

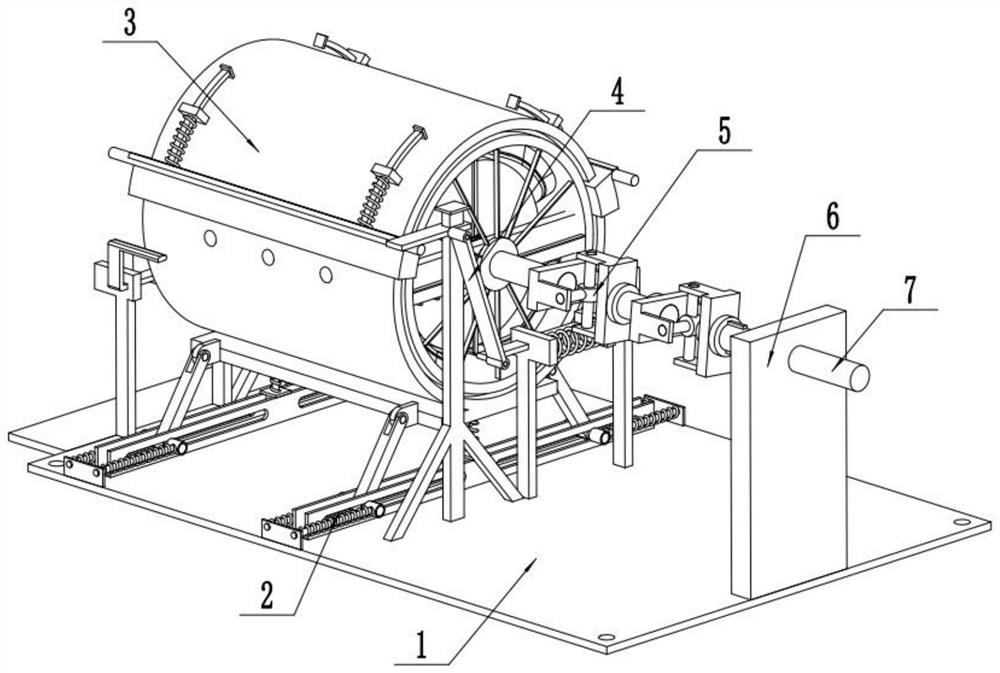

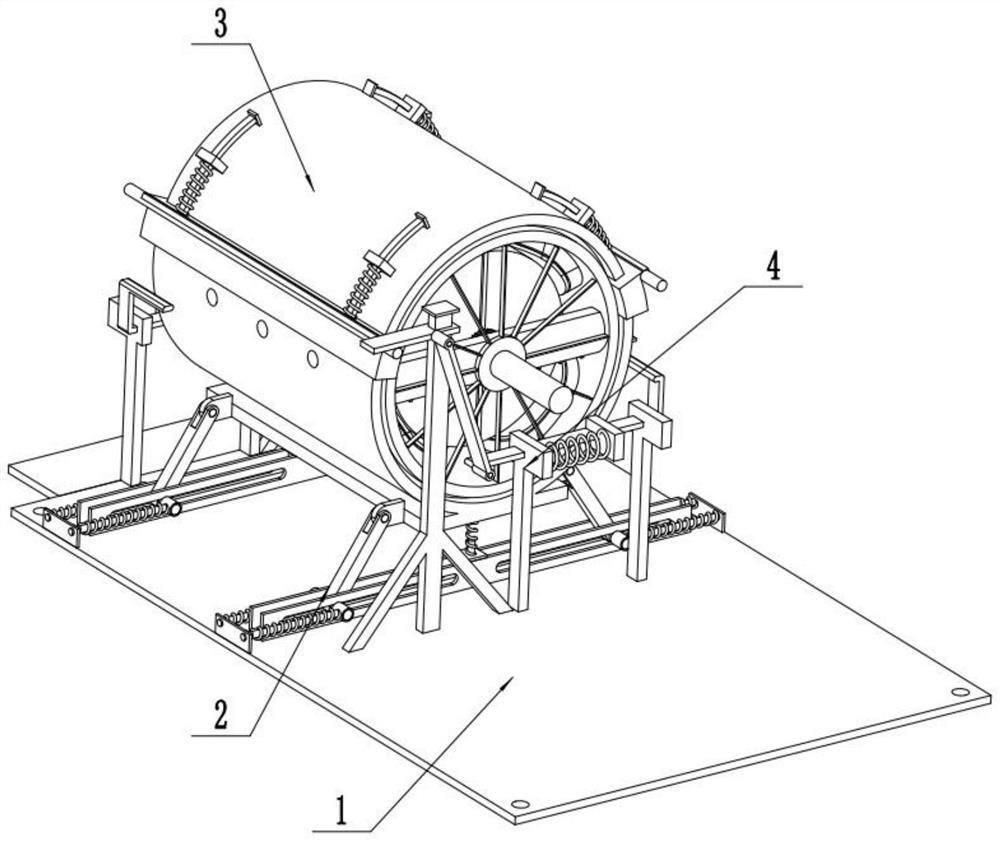

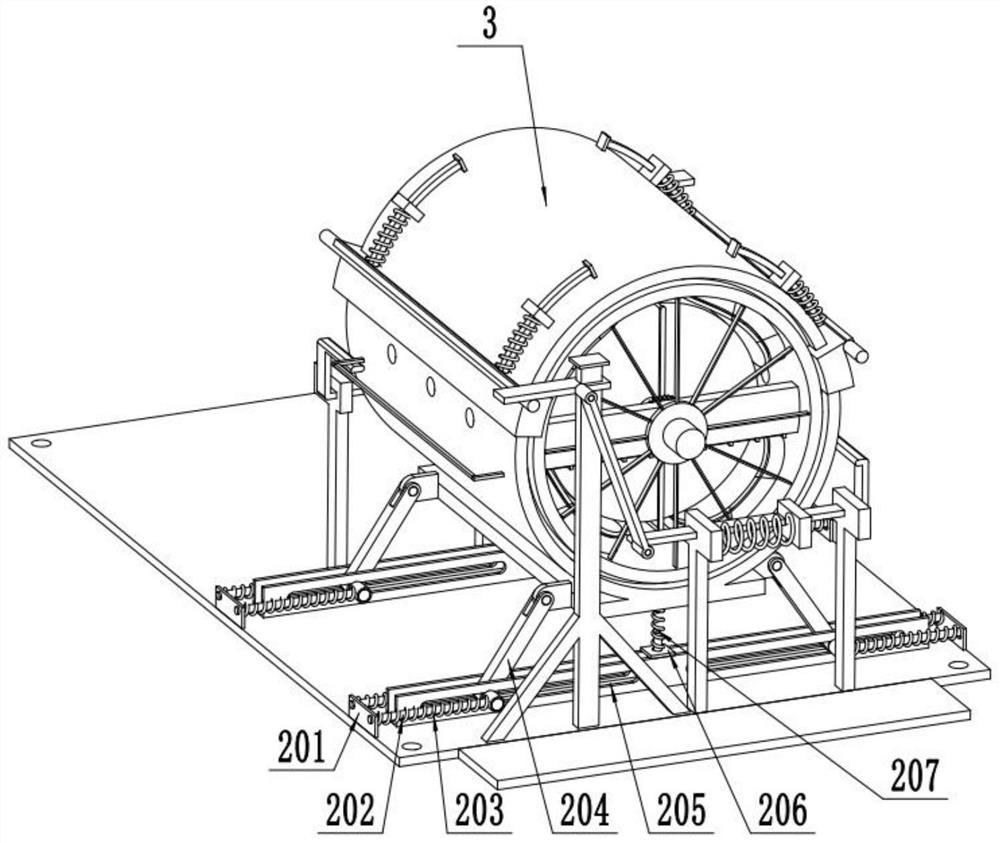

[0022] Example: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a medical miniature brushless motor includes a base 1, a rail assembly 2, a power output assembly 3, a damping assembly 4, a universal joint 5, a rotating seat 6, an output shaft 7 and a dust removal assembly 8, and the base 1 is fixedly installed Inside the motor casing, the base 1 provides the installation and fixing foundation for the medical miniature brushless motor. The base 1 is fixedly mounted with a track assembly 2. In this embodiment, there are two sets of track assemblies 2, and a power is slidably installed on the track assembly 2. The output assembly 3, the power output assembly 3 includes a winding installation cylinder 301, the winding installation cylinder 301 is slidably installed on the track assembly 2, the winding installation cylinder 301 is provided with a rotor 310 and a winding coil 311, and the winding coil 311 is fixedly installed on the winding installation cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com