Technological process of thermochemistry dehydrating for ultra thick oil

A process method and ultra-heavy oil technology, applied in the field of thermochemical dehydration of ultra-heavy oil, can solve the problems of high viscosity of ultra-heavy oil, complicated process, complex equipment, etc., and meet the requirements of low temperature resistance, low operating cost, and The effect of less heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

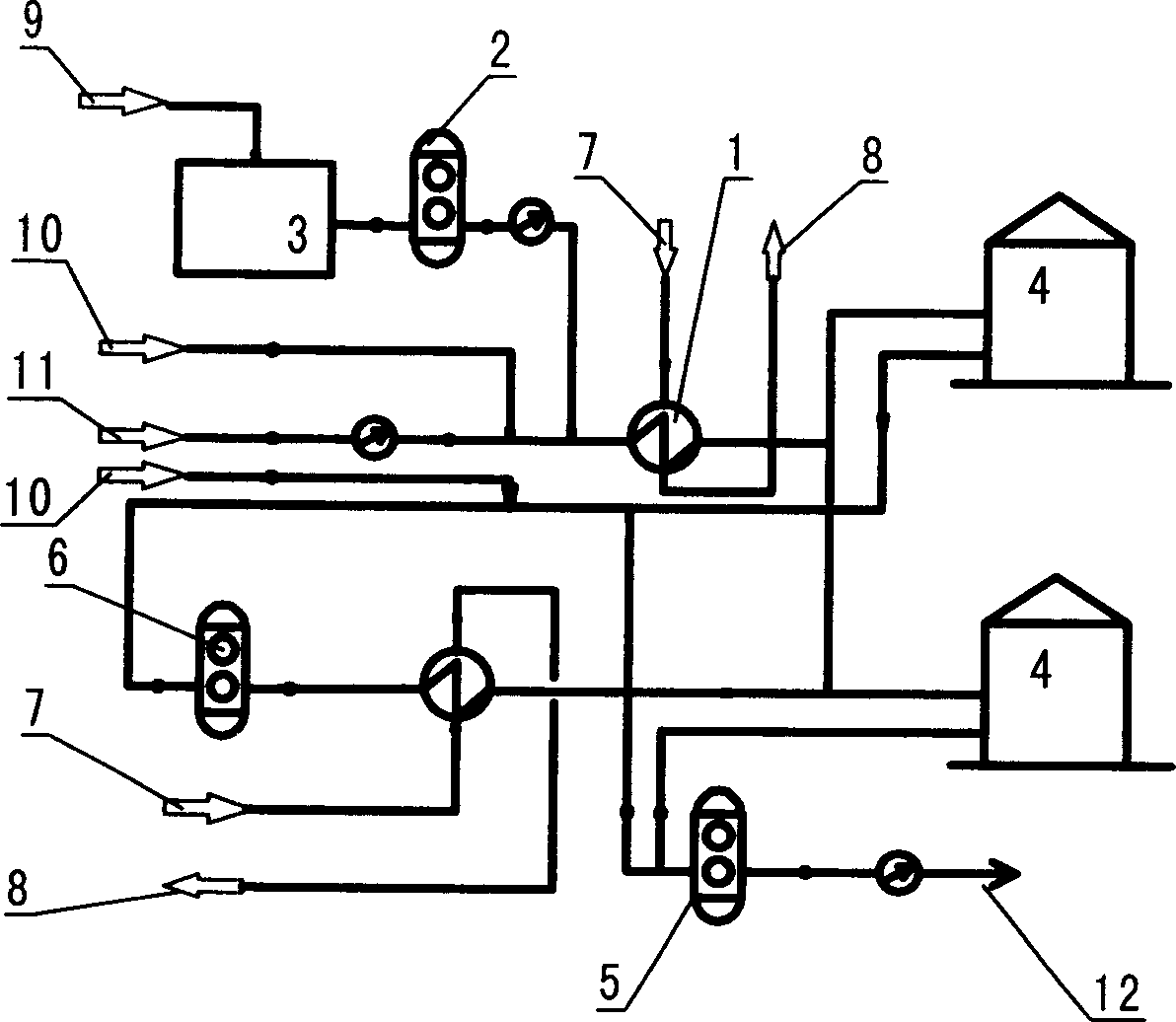

Embodiment 1

[0018] Embodiment 1: One-stage static sedimentation dehydration (for ultra-heavy oil with a water content lower than 50%) process: the entry of super-heavy oil is mainly carried out by pipeline transportation and vehicle pulling, and the crude oil is transported through pipelines and oil unloading tanks, that is, pipeline transportation When crude oil enters the station, the incoming oil at 70-75°C is first measured under the condition of pipeline transportation pressure of 0.4MPa, and demulsifiers LH-2 and RS-2 oil-soluble demulsifiers are added, while the crude oil transported into the station by car is firstly ground After weighing, it is unloaded into the oil tank, boosted and metered by the unloading pump, and then added demulsifier and mixed with pipeline crude oil to enter the heat exchanger to raise the temperature to 90°C, and then enter a section of crude oil settling tank for dehydration. Experiments show that The density of heavy oil and the density of water are at ...

Embodiment 2

[0021] Two-stage static sedimentation dehydration process (for ultra-heavy oil with high water content, generally greater than 50%). Crude oil with high water content enters the station. After dosing, the temperature is raised to 80°C through the first-stage heat exchanger, and then enters the first-stage static settling tank. After most of the free water is released, the second-stage dosing, dehydration and boosting are carried out, and the temperature of the second-stage heat exchanger is raised to 90°C. ℃, into the second-stage static settling tank for settling and dehydration. The one-stage and two-stage sedimentation methods are the same static sedimentation dehydration process. The first-stage sedimentation time is 24 hours, and the second-stage sedimentation time is 96 hours. After the sedimentation, the water content of crude oil can be controlled below 5%.

Embodiment 3

[0023] The heating and heat tracing of the super heavy oil dehydration system described in the present invention adopts the indirect heat supply process with heat transfer oil as the heat carrier. Coking, heat transfer oil can be recycled, but no loss. In the static settling tank, a floating oil discharge mechanism is adopted, which floats with the liquid in the tank, so that the oil receiving port is always near the liquid surface, and the oil-water interface will not be disturbed even when the oil is discharged, ensuring the oil discharge The water content in oil is at the lowest value. The patent number of the floating oil delivery mechanism is: ZL95232982.4.

[0024] The structure of the heat exchanger is composed of two-layer spiral tubes, the outer tube is the heat transfer oil heat medium, and the inner tube is the heated super thick oil medium. The heat exchanger is made of stainless steel thin-walled tube material, which is extruded into The corrugated tube-side heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com