High-frequency copper-clad plate and preparation method thereof

A copper-clad laminate and high-frequency technology, which is applied in the field of high-frequency copper-clad laminate and its preparation, can solve problems such as complex process and material pollution, and achieve the effects of simplified process steps, excellent dielectric properties, and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

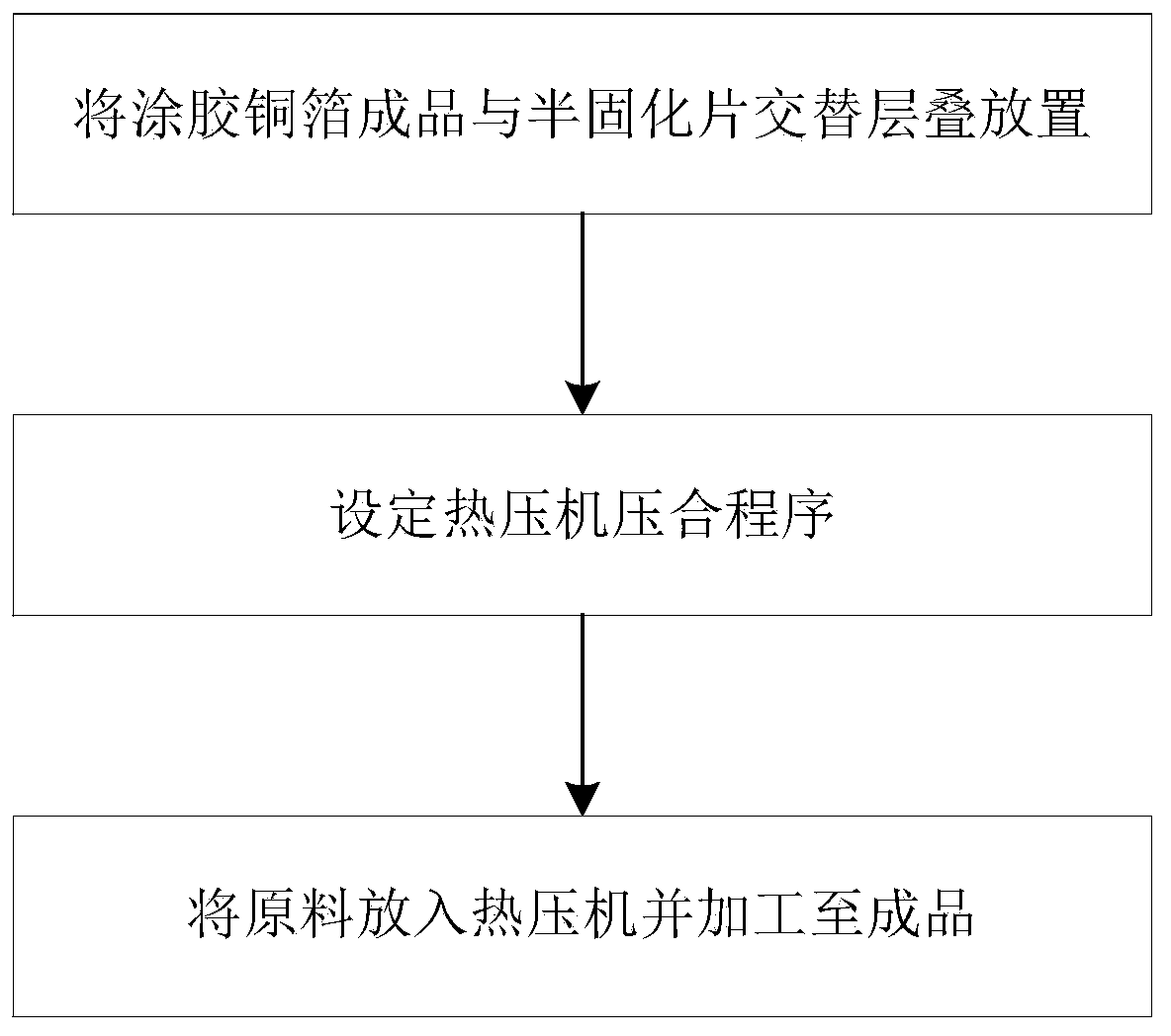

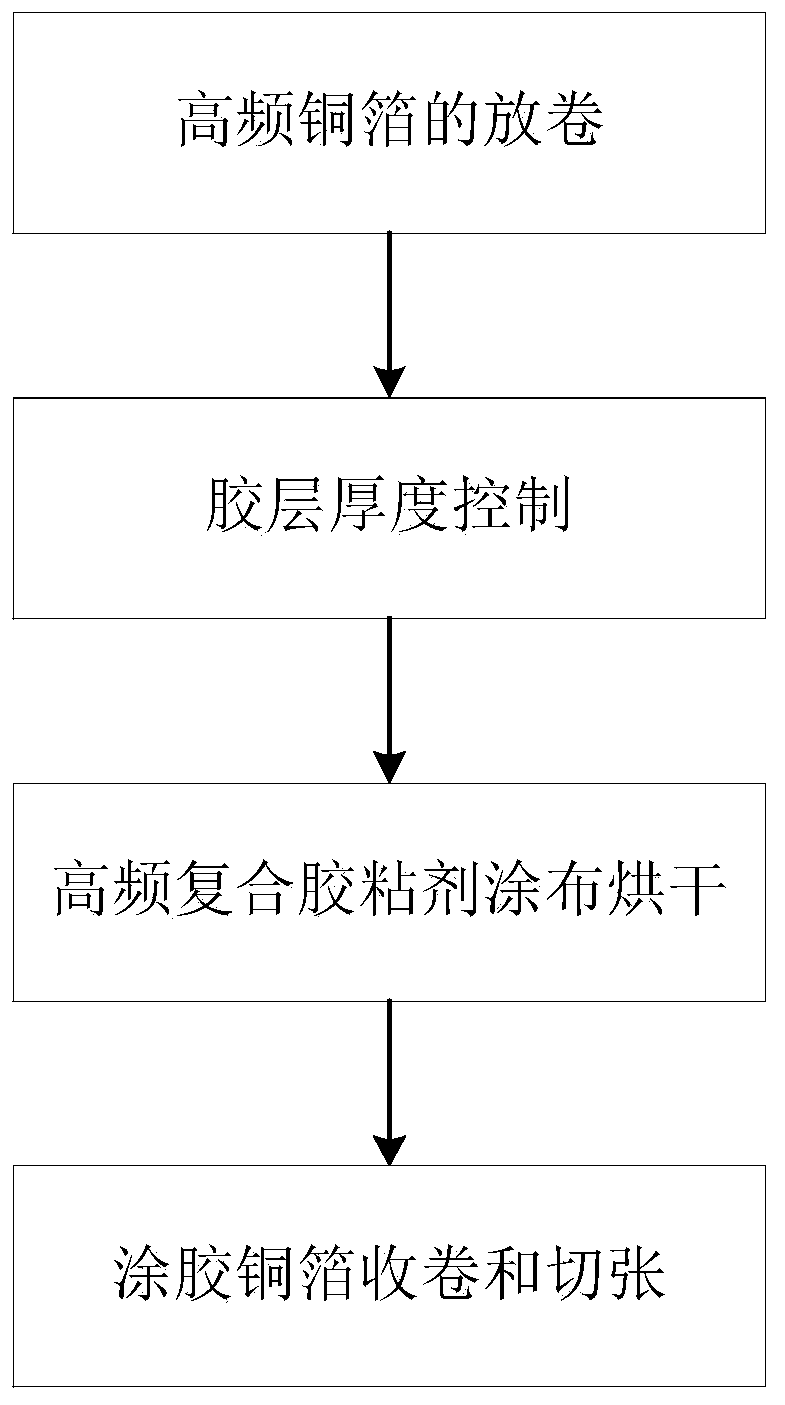

[0031] Below in conjunction with accompanying drawing and specific embodiment the content of the present invention is described in further detail:

[0032] A high-frequency copper-clad laminate comprises glue-coated copper foil and prepregs, and the glue-coated copper foils and prepregs are stacked alternately in sequence. The glued copper foil is coated with a high frequency composite adhesive. The high-frequency composite adhesive comprises 5-10 parts by weight of solvent, 10-20 parts of rubber, 60-90 parts of epoxy resin, 15-20 parts of phenoxy resin, 10-25 parts of phenoxy resin, 10 -20 parts of long chain resin and 10-20 parts of phenolic resin.

[0033] The preparation method of above-mentioned high-frequency composite adhesive comprises the following steps:

[0034] During the stirring process in the constant temperature, high speed and high frequency conversion reactor, 5-10 parts by weight of ethyl acetate, 10-20 parts of rubber, 60-90 parts of epoxy resin, 15-20 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com