A preparation process of ultra-high molecular weight polyethylene sucker rod centralizer

An ultra-high molecular weight, preparation process technology, which is applied in the field of preparation technology of ultra-high molecular weight polyethylene sucker rod centralizers, can solve the problems of limited popularization and application, poor fluidity of ultra-high molecular weight polyethylene, difficult surface hardness, high temperature resistance and wear resistance. performance and other issues, to achieve the effect of improving chemical corrosion resistance, improving processing methods, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Prepare the filler first, then pour the filler into the UHMWPE sucker rod centralizer molding mold, pressurize, heat and cool, open the mold and take out the product;

[0024] The composition weight percentage of each component in the filler is: graphite 1%-1.5%, carbon black 1.5%-2%, calcium stearate 1%-1.5%, pyrogenic silica 0.4%-1%, titanium dioxide 1% %~2%, coupling agent vinyl siloxane 0.5%~1%, ultra-high molecular weight polyethylene 90%~95%, the sum of the above components by weight is 100%;

[0025] Weigh the raw materials according to the composition weight percentage of each component, grind the large particles in the raw materials to make the particles below 40 mesh and uniform in size, pour the weighed graphite, carbon black, pyrogenic silica and titanium dioxide into the Stir in a high-speed mixer, stir for 15-20 minutes, add coupling agent vinyl siloxane and stir for 10-13 minutes, then add calcium stearate and stir for 5-8 minutes, finally add ultra-high ...

Embodiment 2

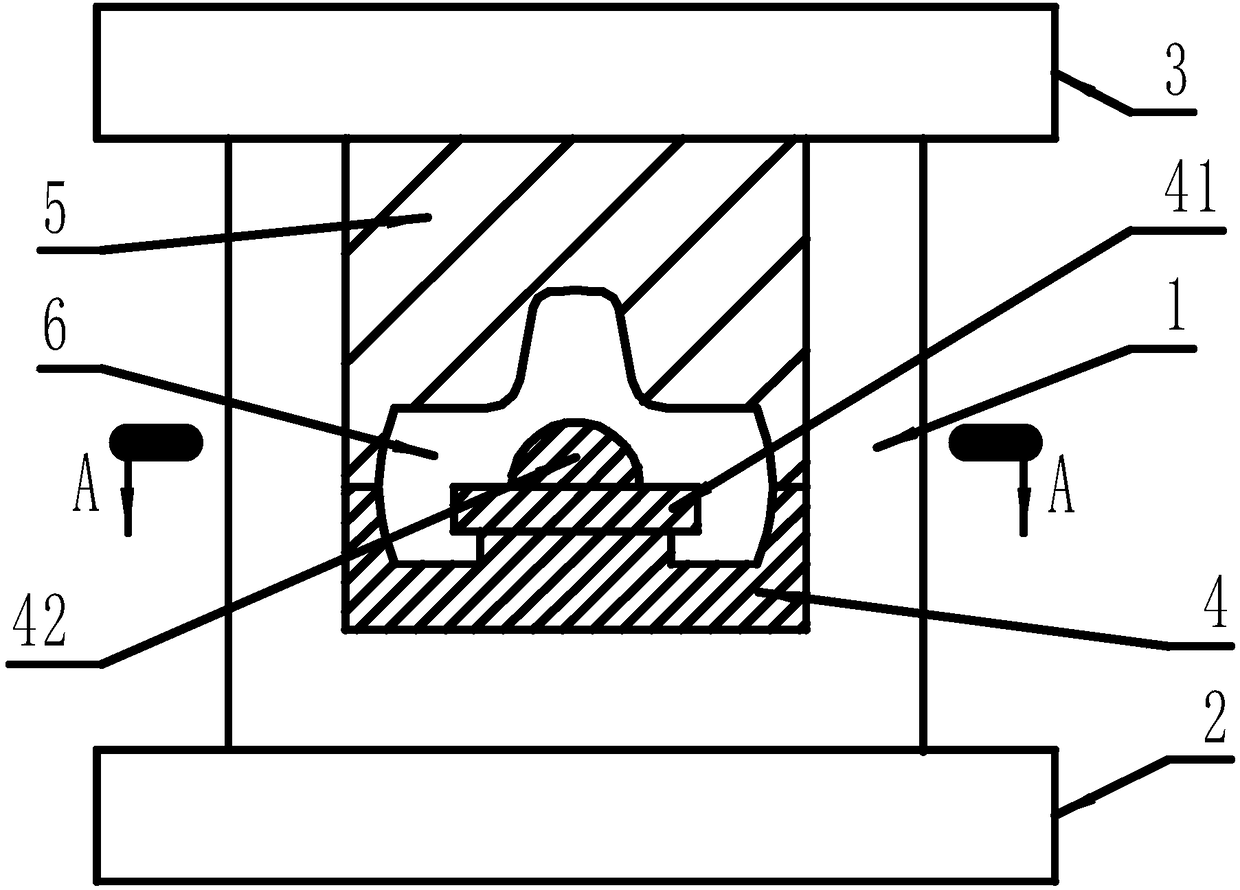

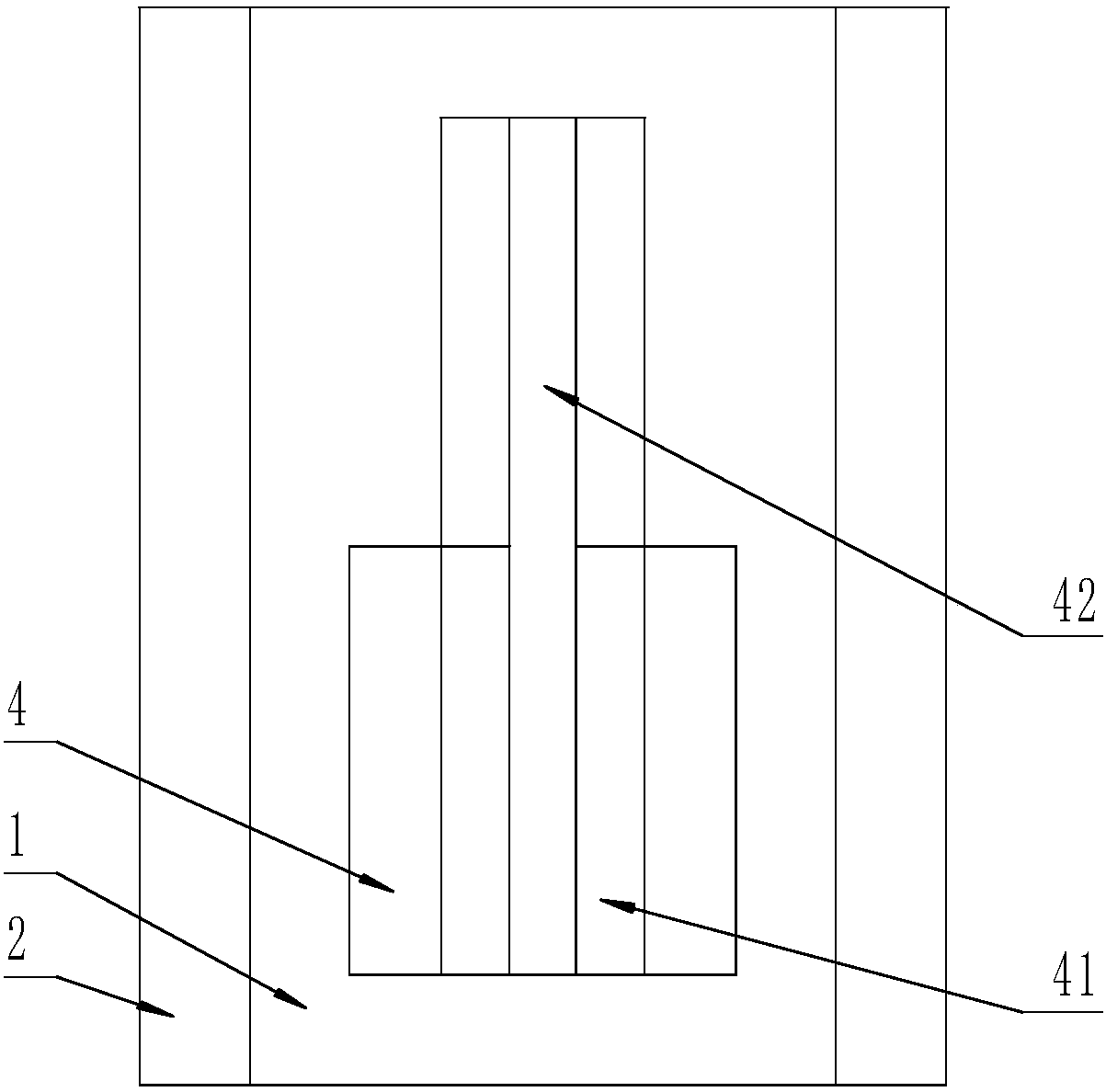

[0028] Put the lower mold 4 of the sucker rod centralizer into the mold cavity first, put the rectangular backing plate 41 into the cube cavity above the lower mold 4 of the sucker rod centralizer, and put the semi-cylindrical mold 42 on the top of the backing plate 41 And located on the center line of the upper surface of the sucker rod centralizer lower mold 4, the insert rod on the lower surface of the semi-cylindrical mold 42 is inserted into the backing plate 41 and the socket of the sucker rod centralizer lower mold 4, so that the sucker rod centralizer The lower mold 4, the backing plate 41 and the semi-cylindrical mold 42 are connected as a whole, and the prepared filler is evenly poured over the lower mold 4, the backing plate 41 and the semi-cylindrical mold 42 of the sucker rod centralizer, and the upper surface of the filler is Spread evenly, the upper template 3 is fixed above the upper mold 5 of the sucker rod centralizer, the upper mold 5 of the sucker rod centra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com