Plastic extrusion screw rod of PC (poly carbonate) thin film

A technology for extruding screw and plastic, which is applied in the field of plastic extrusion screw, which can solve the problems of poor plasticization of materials, affecting quality, equipment maintenance and service life, and peeling off of the chrome layer on the surface of the screw, so as to avoid shear decomposition and shorten plastic melting time, reducing the effect of melt crystal point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

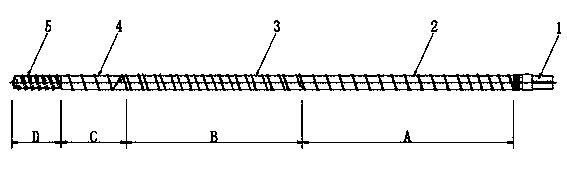

[0019] see figure 1 As shown, a plastic extruding screw of PC film is made of 48CrMo steel as a whole, including a screw main body 1, a feed section A, a melting section B, a compression section C, and an extrusion section D. The screw main body 1 The length is 40-45cm, the feeding section A, the melting section B, the compression section C, and the extrusion section D are provided with raised threads, and the feeding section A is provided with a thread 2, and the thread 2 adopts a gradual change Root diameter structure, the melting section B is provided with a main thread 3, the main thread 3 adopts a cross gradient root diameter structure, the compression section C is provided with a secondary thread 4, and the extrusion section D adopts a spiral convex nail 5 structures.

[0020] The above descriptions are only preferred embodiments of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com