Weaponry field sealing and storage envelope, composite material for weaponry field sealing and storage outer package and preparation method of composite material

A composite material and outer packaging technology, applied in chemical instruments and methods, packaging, wrapping paper, etc., can solve the problems of easy corrosion of the surface of the sealed device weapon, easy perforation and tearing at the tip of the weapon, and low strength of the sealed envelope, etc. Achieve the effect of improving storage reliability, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

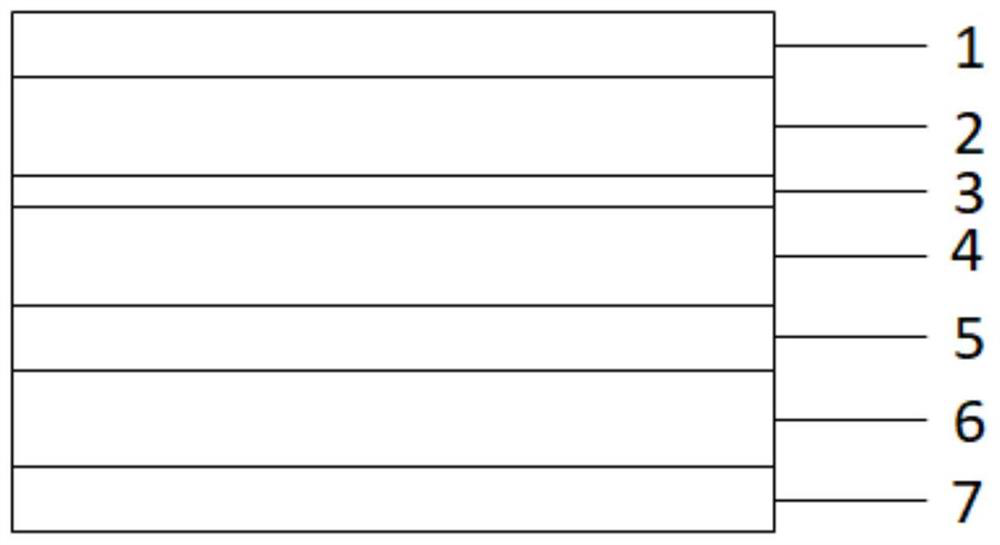

[0042] The present invention also provides a preparation method of a composite material used for field sealing of weapons and equipment, including:

[0043] S1: Add 1-2wt% of white masterbatch, 10-15wt% of aluminum silver paste, and 12-15wt% of mica powder to the silicone resin, control the water content below 300ppm after mixing, and flow through melt extrusion Or form an anti-corrosion layer by plastic-absorbing process, and the thickness is controlled at 0.04-0.05mm;

[0044] S2: Coating solvent-based polyurethane adhesive or solvent-free polyurethane adhesive on the lower surface of the anti-corrosion layer with an anilox roller to form the first adhesive layer, and bond a high barrier layer on the other side of the first adhesive layer , the first adhesive layer is pre-cured, the pre-curing temperature is 65-75°C, the high barrier layer is made of PVDC or aluminum foil obtained by vacuum aluminum plating technology, and the thickness is 0.013-0.015mm;

[0045] S3: Carbon...

Embodiment 1

[0050] Preparation of anti-corrosion layer

[0051] Silicone resin is used as film-forming resin, the amount of white masterbatch is 1.5wt%, the amount of aluminum silver paste is 12wt%, and the amount of mica powder is 12wt%, mixed evenly to control the moisture content below 300ppm and through the method of melt extrusion casting calendering process Form a white organosilicon resin composite material film, that is, an anti-corrosion layer, with a thickness of 0.05 mm.

[0052] On the lower surface of the anti-corrosion layer, the solvent-based polyurethane adhesive is coated with an anilox roller and precured, and the precuring temperature is 65°C.

[0053] High barrier layer

[0054] PVDC is used as a high barrier layer directly bonded to the lower surface of the anti-corrosion layer, with a thickness of 0.013mm.

[0055] Substrate layer

[0056] It is a high-strength carbon fiber-reinforced composite material. The high-strength carbon fiber-reinforced composite material...

Embodiment 2

[0061] Preparation of anti-corrosion layer

[0062] Silicone resin is used as film-forming resin, the amount of white masterbatch is 1.8wt%, the amount of aluminum-silver paste is 14wt%, and the amount of mica powder is 14wt%. Mix evenly to control the moisture below 300ppm and form white silicone by means of blistering process Resin-like composite material film, that is, the anti-corrosion layer, has a thickness of 0.04mm.

[0063] On the lower surface of the anti-corrosion layer, the solvent-free polyurethane adhesive is coated with an anilox roller and cured, and the pre-curing temperature is 70°C.

[0064] High barrier layer

[0065] The aluminum foil formed by vacuum aluminum plating technology is directly bonded on the lower surface of the anti-corrosion layer as a high barrier layer, with a thickness of 0.014mm.

[0066] Substrate layer

[0067] It is a carbon fiber reinforced composite material, using carbon fiber reinforced composite material as the base material l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com