Pattern machining technology for metal product machining

A technology for pattern processing and metal products, applied in the field of pattern processing, can solve the problems that affect the appearance of patterns on the surface of metal products, the patterns of metal products are difficult to achieve a three-dimensional effect, the patterns are easy to be worn or scratched, etc. It is not easy to be worn or scratched, and the effect of improving the aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

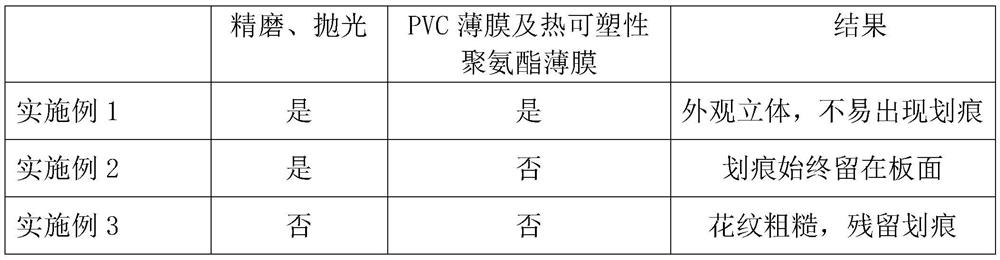

Embodiment 1

[0026] A pattern processing process for processing metal products, comprising the following steps:

[0027] S1. Cleaning: First, clean the base surface of the metal sheet, soak the metal substrate in a neutral degreasing and rust remover for 30 minutes, remove the oil and impurities on the surface of the metal sheet, and then scrape off the residue on the surface.

[0028] S2. Grinding: the metal substrate is limited by the clamping mechanism, and the surface of the metal substrate is polished by a grinding mechanism at 2700r / min, so that the surface of the metal substrate is smooth and thorn-free.

[0029] S3. Pattern engraving: the pattern pattern is digitally processed by the computer, and then the processed data of the pattern pattern is programmed and converted into numerical control codes, and the pattern pattern is converted into operation instructions for numerical control grinding processing equipment through programming processing. After cleaning and polishing, the m...

Embodiment 2

[0041] A pattern processing process for processing metal products, comprising the following steps:

[0042] S1. Cleaning: First, clean the base surface of the metal sheet, soak the metal substrate in a neutral degreasing and rust remover for 30 minutes, remove the oil and impurities on the surface of the metal sheet, and then scrape off the residue on the surface.

[0043] S2. Grinding: the metal substrate is limited by the clamping mechanism, and the surface of the metal substrate is polished by a grinding mechanism at 2700r / min, so that the surface of the metal substrate is smooth and thorn-free.

[0044] S3. Pattern engraving: the pattern pattern is digitally processed by the computer, and then the processed data of the pattern pattern is programmed and converted into numerical control codes, and the pattern pattern is converted into operation instructions for numerical control grinding processing equipment through programming processing. After cleaning and polishing, the m...

Embodiment 3

[0052] A pattern processing process for processing metal products, comprising the following steps:

[0053] S1. Cleaning: First, clean the base surface of the metal sheet, soak the metal substrate in a neutral degreasing and rust remover for 30 minutes, remove the oil and impurities on the surface of the metal sheet, and then scrape off the residue on the surface.

[0054] S2. Grinding: the metal substrate is limited by the clamping mechanism, and the surface of the metal substrate is polished by a grinding mechanism at 2700r / min, so that the surface of the metal substrate is smooth and thorn-free.

[0055] S3. Pattern engraving: the pattern pattern is digitally processed by the computer, and then the processed data of the pattern pattern is programmed and converted into numerical control codes, and the pattern pattern is converted into operation instructions for numerical control grinding processing equipment through programming processing. After cleaning and polishing, the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com