High-efficiency low-cost solar cell diffusion technology

A solar cell and diffusion process technology, applied in the field of solar cell diffusion process, can solve problems such as unsatisfactory diffusion resistance uniformity and repeatability, low conversion efficiency of solar cells, long diffusion process time, etc., to reduce internal defects, reduce Process gas cost, effect of reducing diffusion process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

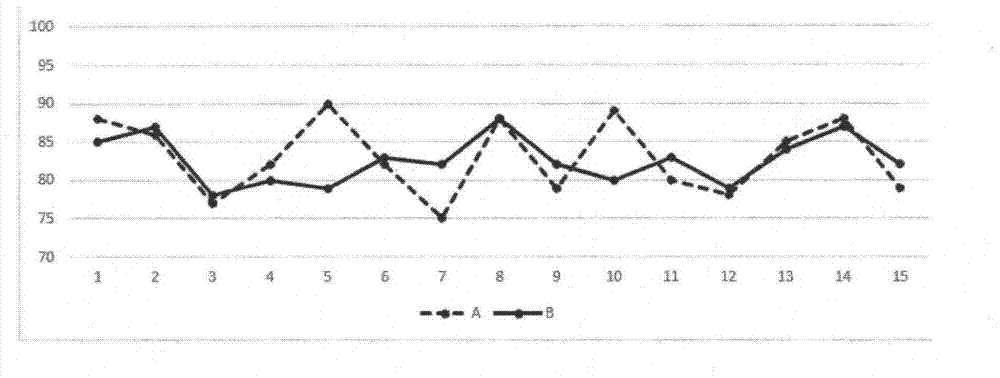

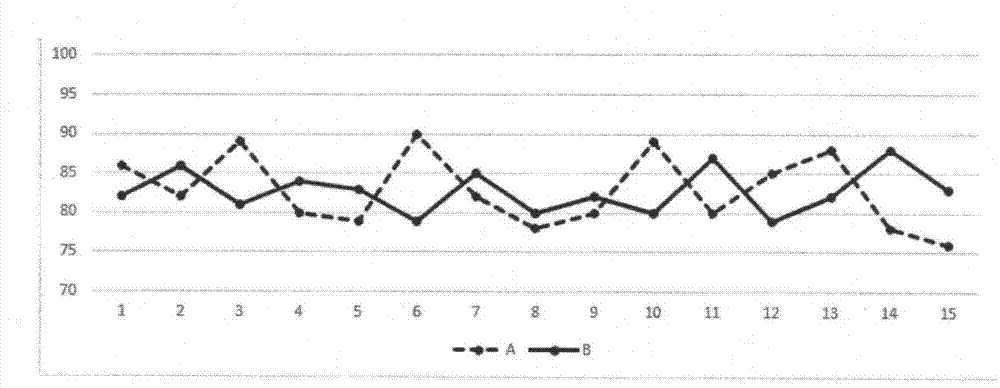

Image

Examples

Embodiment 1

[0037] Put P-type polycrystalline raw silicon wafers on the surface for acid velvet, cleaning and drying, then put them into diffusion quartz boats, place 200 silicon wafers in each boat, and then put 2 sets of quartz boats on the boat support of the cantilever paddle of the diffusion furnace Perform the following diffusion process:

[0038] Step 1: Push the silicon wafer loaded into the quartz boat into the diffusion furnace at the set temperature of 730 degrees Celsius, and feed 10000ml / min of large nitrogen.

[0039] Step 2: Immediately after entering the boat process, keep the temperature rising for 300 seconds in a large nitrogen environment, so that the actual temperature reaches 730 degrees Celsius.

[0040] Step 3: Increase the set temperature to 760 degrees Celsius, maintain a large nitrogen environment, and feed 2000ml / min of oxygen for 600 seconds.

[0041] Step 4: Under the large nitrogen environment of 760 degrees Celsius, pass through the phosphorus source to ca...

Embodiment 2

[0054] Put P-type polycrystalline raw silicon wafers into surface acid texture, wash and dry them, then put them into diffusion quartz boats, place 200 silicon wafers in each boat, and then put 2 groups of quartz boats on the boat holders of the cantilever paddles of the diffusion furnace Perform the following diffusion process:

[0055] Step 1: Push the silicon wafer loaded into the quartz boat into the diffusion furnace at the set temperature of 750 degrees Celsius, and feed 15000ml / min of large nitrogen.

[0056] Step 2: Immediately after entering the boat process, keep the temperature rising for 300 seconds in a large nitrogen environment, so that the actual temperature reaches 750 degrees Celsius.

[0057] Step 3: Increase the set temperature to 780 degrees Celsius, maintain a large nitrogen environment, and feed 1000ml / min of oxygen for 600 seconds.

[0058] Step 4: Under the large nitrogen environment of 780 degrees Celsius, pass through the phosphorus source to carry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com