Steel plate for wind power tower in low temperature and manufacturing method thereof

A steel plate production method and wind power tower technology, applied in the field of low-carbon micro-alloy steel, can solve the problems of impact performance and high production cost, and achieve the effects of improving safety and stability, improving production efficiency and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

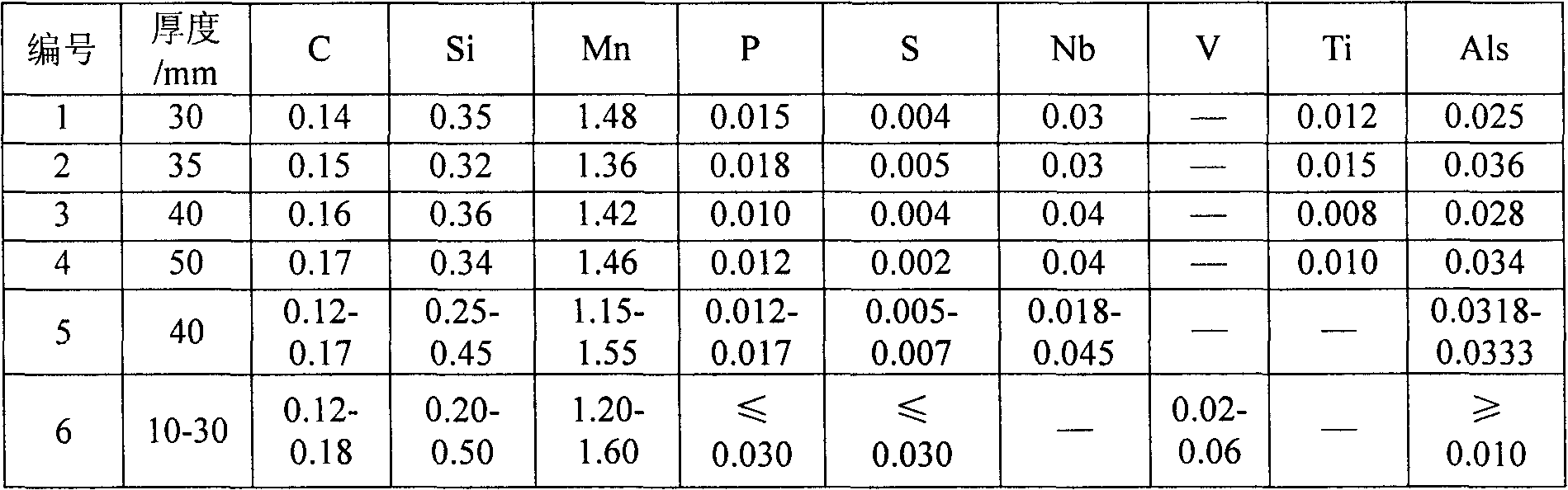

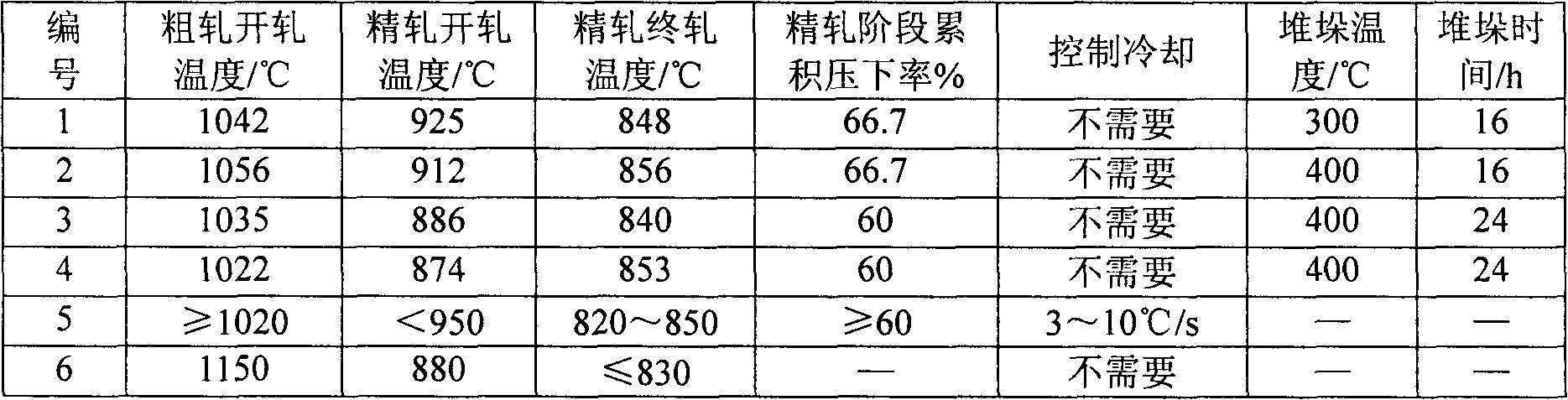

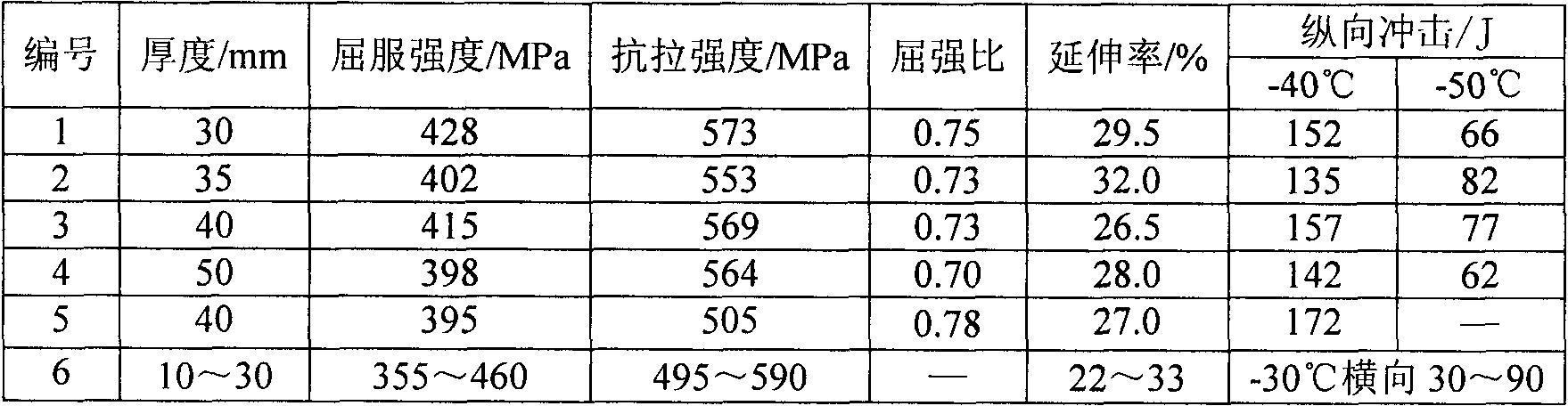

[0017] The chemical composition of Examples (1~4) and Comparative Examples (5~6) is shown in Table 1; the corresponding production process is shown in Table 2; the reduction rate of each pass of the embodiment is shown in Table 3; the comprehensive performance is shown in Table 4

[0018] Table 1 chemical composition (wt%)

[0019]

[0020] Table 2 Production process

[0021]

[0022] The reduction rate of each pass of the embodiment of table 3

[0023] Steel plate thickness

30mm

35mm

40mm

50mm

pass

Reduction rate%

rough rolling 1

9.6

9.2

9.6

9.7

2

9.7

9.7

10.2

10.3

3

9.8

11.7

12.3

11.5

4

9.8

13.2

14.6

13.0

5

10.8

14.0

14.5

14.4

6

12.2

12.6

13.1

12.5

7

12.3

11.0 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com