Semi-aromatic transparent polyamide material and preparation method thereof

A semi-aromatic and polyamide technology, which is applied in the preparation of the polyamide material and in the field of semi-aromatic transparent polyamide materials, can solve the problem that the elongation at break of thermal performance materials is difficult to meet, and the regularity of macromolecular chains and mechanical properties are destroyed. The problem of high price and other problems can reduce internal defects, improve integrity and stability, and enhance antioxidant properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

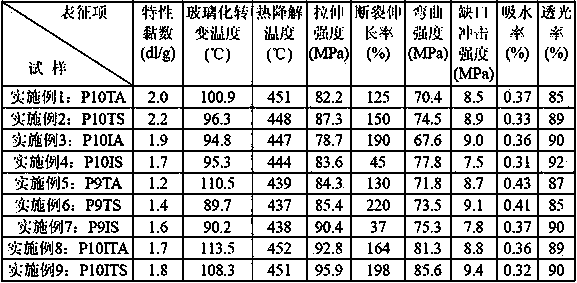

Examples

Embodiment 1

[0025] Mix 135.2g of amide 10T salt with 202.8g of amide 610 salt, 0.68g of NP-508, 1.02g of N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl) Hexamethylenediamine, 0.68g sodium hypophosphite, 0.10g 4,4-bis(5-methyl-2-benzoxazolyl)stilbene, 150g distilled water were added to the polymerization kettle, nitrogen gas was charged and discharged three times and then passed into 0.1MPa nitrogen, start to heat up; raise the temperature to 200°C within 2h, keep it warm for 1h, then gradually raise the temperature to 270°C, raise the pressure to 2.5MPa, keep it for 2h, then slowly release the gas to normal pressure within 1h, and continue to keep constant temperature After stirring for 4 hours, discharge to obtain semi-aromatic transparent copolymerized polyamide P10TA.

Embodiment 2

[0027] Mix 169g amide 10T salt with 169g amide 1010 salt, 0.51g NP-508, 1.02g N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionyl) hexamethylenediamine, Add 0.51g of sodium hypophosphite, 0.14g of 4,4-bis(5-methyl-2-benzoxazolyl)stilbene, and 200 grams of distilled water into the polymerization kettle, charge and discharge nitrogen three times, and then pass in 0.1MPa nitrogen , start to heat up; raise the temperature to 190°C within 1h, keep it warm for 1.5h, then gradually raise the temperature to 240°C, raise the pressure to 3.0MPa, keep it for 2.5h, then slowly release the gas to normal pressure within 2h, and continue to stir at constant temperature After 1.5 hours, the material is discharged, and the semi-aromatic transparent copolymerized polyamide P10TS is obtained.

Embodiment 3

[0029] Add 240g of amide 10I salt and 160g of amide 610 salt, 0.60g of NP-509, 1.80g of sodium hypophosphite, 0.12g of 4,4-bis(5methyl-2-benzoxazolyl)stilbene, and 300g of distilled water Into the polymerization kettle, fill and discharge nitrogen three times, then pass through 0.1MPa nitrogen, start to heat up, raise the temperature to 200°C within 2h, keep it for 3h; then gradually raise the temperature to 290°C, raise the pressure to 1.5MPa, keep it for 2h, Then slowly deflate to normal pressure within 3 hours, continue to stir at constant temperature for 3 hours, and discharge the material to obtain semi-aromatic transparent copolymerized polyamide P10IA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com