Slag glass ceramic pipe and preparation method thereof

A technology of glass-ceramics and glass tubes, applied in glass production, etc., can solve the problems of reduced mechanical strength and anti-wear performance, high scrap rate, prone to pores and shrinkage cavities, etc., to achieve strong crystallization ability and not easy to deform Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

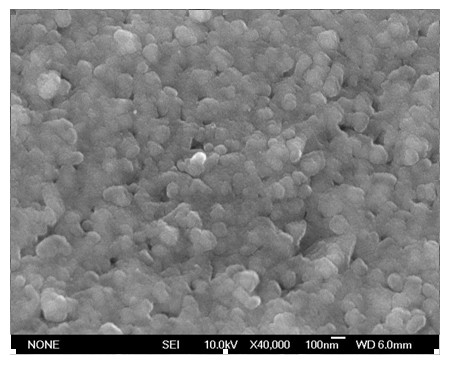

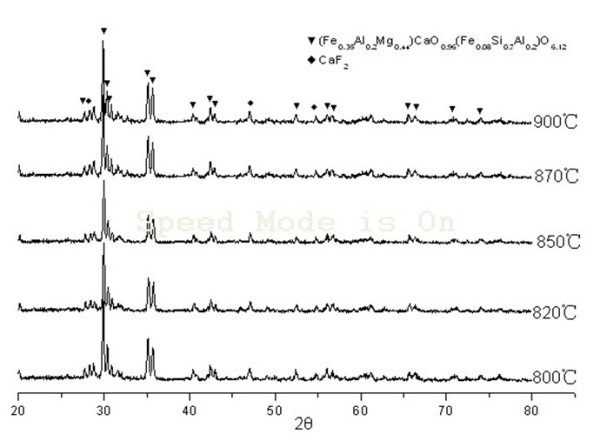

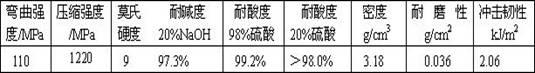

Image

Examples

Embodiment 1

[0048] Embodiment 1: slag glass-ceramics pipe and its preparation method:

[0049] (1) Raw material ratio: 27.3% fly ash, 45.1% slag after beneficiation of Baiyunebo tailings, 18.2% quartz sand, 3.1% dolomite, 2.6% sodium carbonate, and 3.7% borax.

[0050] (2) Mixing: Put the weighed raw materials into the ball mill mixer and mix for 70 minutes;

[0051] (3) Melting: Add the mixed raw materials into the glass melting furnace for melting, and the melting temperature is 1350-1450°C;

[0052] (4) Centrifugal casting molding: Preheat the mold to 400°C, use a ladle to pick up the glass liquid (the temperature of the glass liquid is 1150°C), pour it into a high-speed rotating mold, and centrifugally form it at 650 rpm. Release the mold when the mold temperature drops to 730°C.

[0053] (5) Annealing, nucleation and crystallization treatment: anneal the formed glass tube at 620°C for 2 hours, nucleate at 680°C for 2 hours, crystallize at 850°C for 4 hours, and finally the glass tu...

Embodiment 2

[0059] Embodiment 2: slag glass-ceramic pipe material and its preparation method

[0060] (1) Raw material ratio: 25.6% fly ash, 24.4% blast furnace slag, 21.1% slag after beneficiation of Baiyun Obo tailings, 18.9% quartz sand, 3.5% feldspar, 2.4% sodium carbonate, 4.1% borax;

[0061] (2) Mixing: Put the weighed raw materials into the ball mill mixer and mix for 60 minutes;

[0062] (3) Melting: Add the mixed raw materials into the glass melting furnace for melting, and the melting temperature is 1350-1450°C;

[0063] (4) Centrifugal casting molding: Preheat the mold to 450°C, take the molten glass with a ladle (the temperature of the molten glass is 1200°C), pour it into a high-speed rotating mold, and centrifugally form it at a speed of 700 rpm. Release the mold when the mold temperature drops to 750°C;

[0064] (5) Annealing, nucleation and crystallization treatment: anneal the formed glass tube at 630°C for 4 hours, nucleate at 730°C for 3 hours, crystallize at 870°C f...

Embodiment 3

[0070] Embodiment 3: Slag glass-ceramic pipe material and its preparation method

[0071] (1) Raw material ratio: 28.8% fly ash, 21.6% steel slag, 20.7% slag after beneficiation of Baiyun Obo tailings, 18.3% quartz sand, 3.2% albite feldspar, 2.1% sodium carbonate, 5.3% borax;

[0072] (2) Mixing: Put the weighed raw materials into the ball mill mixer and mix for 60 minutes;

[0073] (3) Melting: Add the mixed raw materials into the glass melting furnace for melting, and the melting temperature is 1350-1450°C;

[0074] (4) Centrifugal casting molding: Preheat the mold to 500°C, take the molten glass with a ladle (the temperature of the molten glass is 1250°C), pour it into a high-speed rotating mold, and centrifugally form it at a speed of 750 rpm. Demoulding when the mold temperature drops to 730°C;

[0075] (5) Annealing, nucleation, and crystallization treatment: Anneal the formed glass tube at 620°C for 5 hours, nucleate at 800°C for 3 hours, crystallize at 900°C for 2 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com