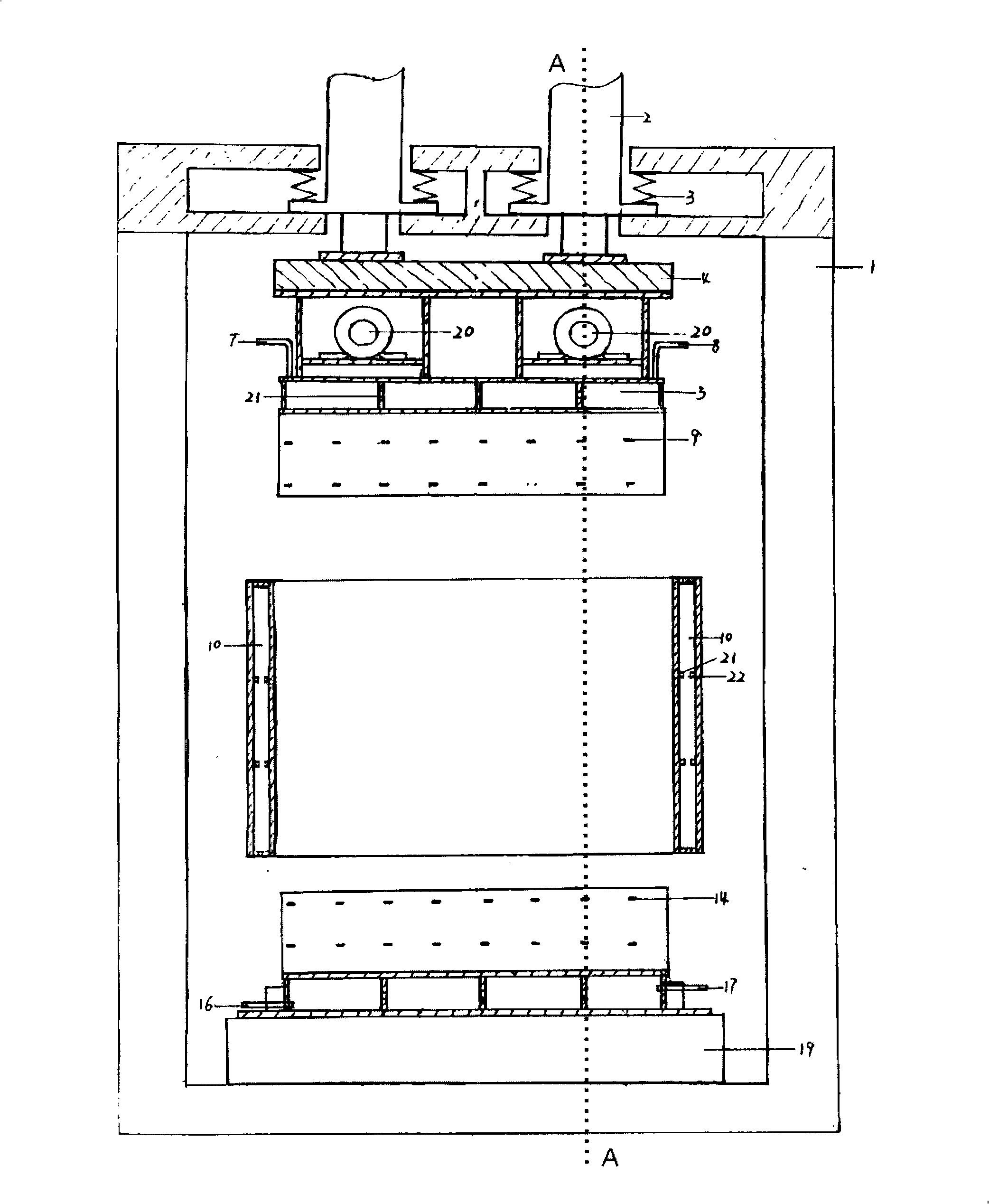

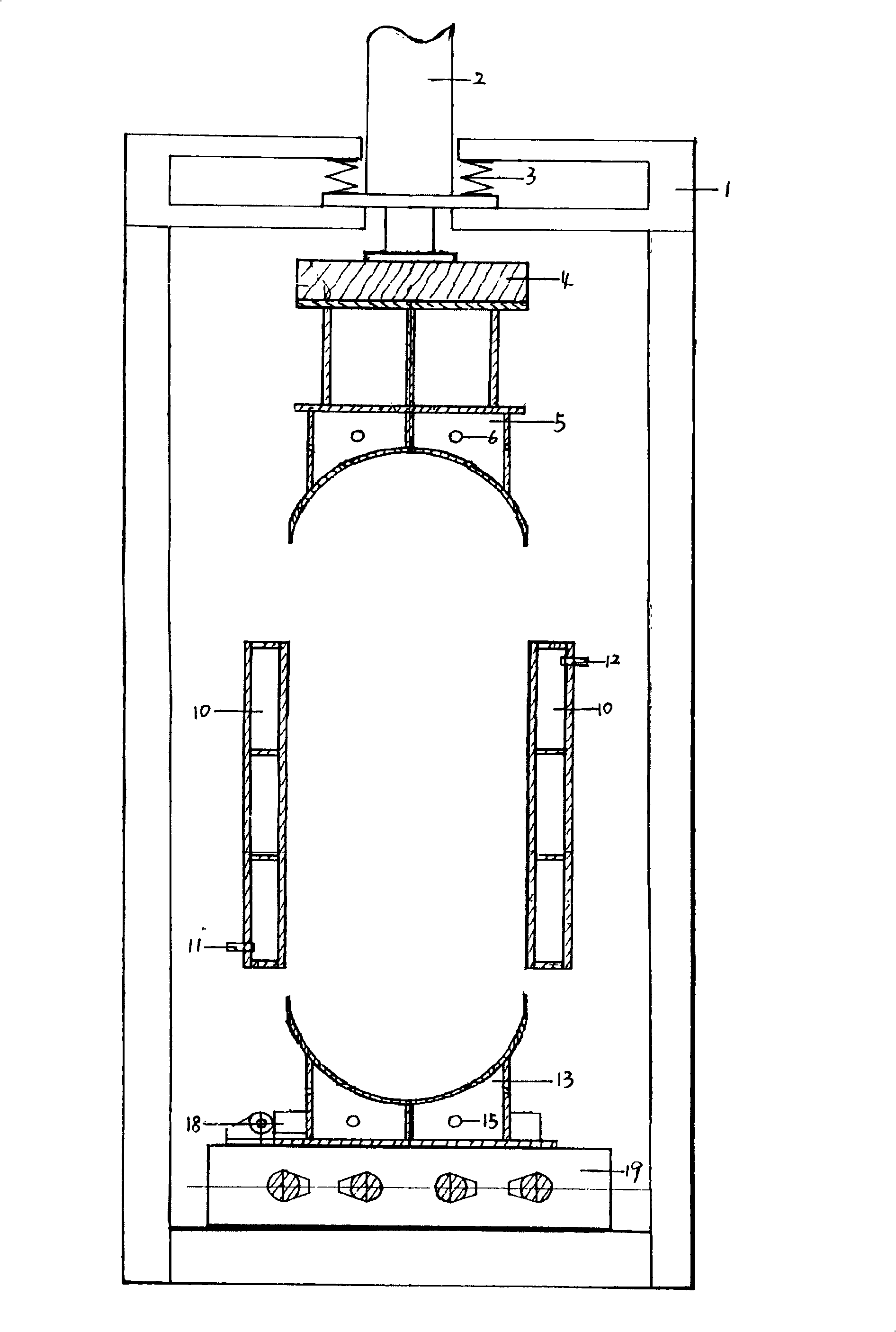

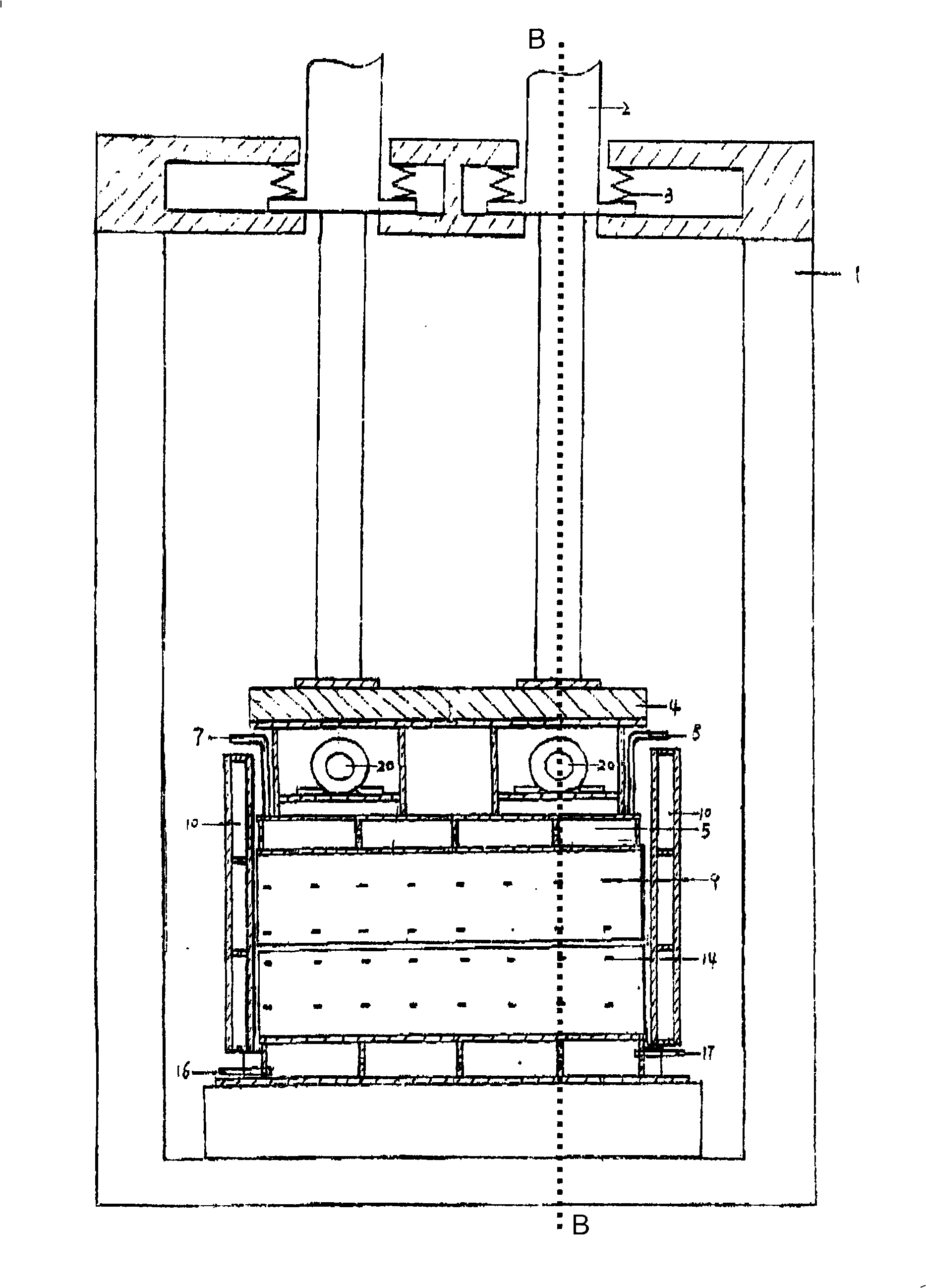

Carbon electrode horizontal type bidirectional vibration molding technique and special forming equipment

A technology of two-way vibration and forming process, which is applied in the direction of battery electrodes, ceramic forming machines, material forming presses, etc., can solve problems such as difficulty in uniform transmission of exciting force, high pole breaking rate, product defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A horizontal two-way vibration forming process of a carbon electrode of the present invention comprises the following steps:

[0032] 1. Select the following raw materials in weight percentage:

[0033] Electric calcined coal (grain) 21%; roasted crushed 8%; graphite crushed 19%; phosphorus flake graphite powder 1.5%; calcined petroleum coke powder 31%; coal tar pitch 19.5%; the sum of the weight of each component is 100%.

[0034] Among the above-mentioned raw materials, electric calcined coal (granules) is uniformly mixed with four different sizes of electric calcined coal (granules), among which electric calcined coal (granules) with a size of ¢16-8mm accounts for material) 27% of the total weight, ¢8-4mm electric calcined coal (pellet) accounts for 45%, ¢4-2mm electric calcined coal (pellet) accounts for 19%, and ¢2-0mm electric calcined Coal (grain) accounts for 9%; roasted crushed powder is uniformly mixed with two different sizes of roasted crushed powder, of wh...

Embodiment 2

[0045] A horizontal two-way vibration forming process of a carbon electrode of the present invention comprises the following steps:

[0046] 1. Select the following raw materials in weight percentage:

[0047] Electric calcined coal (grain) 22%; roasted crushed 8%; graphite crushed 18%; phosphorus flake graphite powder 1%; calcined petroleum coke powder 31%; coal tar pitch 20%; the sum of the weight of each component is 100%.

[0048] 2. Heating and kneading: Preheat the kneading pot to 140°C, add electric calcined coal (granules), roasted crushed graphite, graphite flakes and graphite powder into the kneading pot under normal pressure, heat to 140°C, and dry mix for 15 minutes , Drain the water in the material, then add the coal tar pitch that has been completely melted and fully allowed to stand, wet mix for 45 minutes, take out the pot in the form of a paste, and discharge it into the hopper.

[0049] 3. Drying: Put the paste in the hopper into the preheated and temperatur...

Embodiment 3

[0055] A horizontal two-way vibration forming process of a carbon electrode of the present invention comprises the following steps:

[0056] 1. Select the following raw materials in weight percentage:

[0057] Electric calcined coal (grain) 23%; roasted crushed 7%; graphite crushed 21%; phosphorus flake graphite powder 0.8%; calcined petroleum coke powder 30%; coal tar pitch 18.2%; the sum of the weight of each component is 100%.

[0058] 2. Heating and kneading: Preheat the kneading pot to 140°C, add electric calcined coal (granules), roasted crushed graphite, graphite flakes and graphite powder into the kneading pot under normal pressure, heat to 140°C, and dry mix for 15 minutes , Drain the water in the material, then add the coal tar pitch that has been completely melted and fully allowed to stand, wet mix for 45 minutes, take out the pot in the form of a paste, and discharge it into the hopper.

[0059] 3. Drying: Put the paste in the hopper into the preheated and temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com