Degradable magnesium alloy plate and bar for fracture internal fixation and preparation methods thereof

A magnesium alloy plate and magnesium alloy technology are applied in the field of preparation of implantable medical materials, which can solve the problems of insufficient strength of the alloy, unfavorable to improve the biocompatibility of the alloy, lack of zinc element in the alloy, etc. Good effect of corrosion resistance, composition and structure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

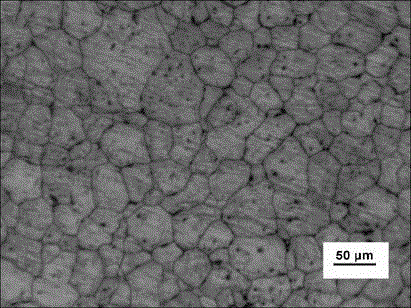

[0023] A degradable magnesium alloy rod for internal fixation of fractures, which is composed of alloying element Ca on the basis of Mg-Zn-Zr alloy, the mass percentage of each component is: Zn is 3.0wt.%, Zr is 0.5wt %, Ca is 0.2 wt.%, Mg is the balance, the content of single impurity elements such as iron, nickel, copper, and aluminum is less than 0.05%, and the total content of various impurities is not more than 0.4%.

[0024] The preparation method of the degradable magnesium alloy rod for internal fixation of fractures has the following steps:

[0025] 1) Add Mg, Zn and Mg-30wt%Zr, Mg-30wt%Ca master alloy into the graphite crucible, and evacuate to 1×10 -2 Pa, pass in argon gas for protection, heat to 720°C and keep it warm for 20 minutes, then fully stir at a speed of 5r / s for 5 minutes and then start to cool down. After the temperature drops to 690°C, pour it into the crystallizer, and take it out when it cools to 269°C. Obtain a round ingot with a diameter of 50mm; ...

Embodiment 2

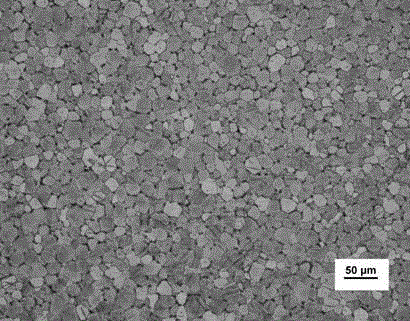

[0030] A degradable magnesium alloy rod for internal fixation of fractures, which is composed of alloying element Sr on the basis of Mg-Zn-Zr alloy, the mass percentage of each component is: Zn is 3.0wt.%, Zr is 0.5wt .%, Sr is 0.3 wt.%, Mg is the balance, the content of single impurity elements such as iron, nickel, copper and aluminum is less than 0.05%, and the total content of various impurities is not more than 0.4%.

[0031] The preparation method of the degradable magnesium alloy rod for internal fixation of fractures has the following steps:

[0032] 1) Add Mg, Zn and Mg-30 wt %Zr, Mg-30 wt %Sr master alloys into the graphite crucible, and evacuate to 1×10 -2 Pa, pass in argon gas for protection, heat to 720°C and keep it warm for 20 minutes, then fully stir at a speed of 5r / s for 5 minutes and then start to cool down. After the temperature drops to 690°C, pour it into the crystallizer, and take it out when it cools to 269°C. A round ingot with a diameter of 50mm is o...

Embodiment 3

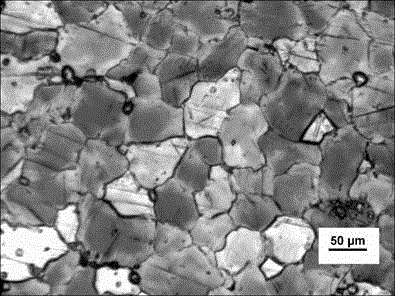

[0037] A kind of degradable magnesium alloy bar material for internal fixation of fractures is formed by adding alloy elements Ca and Ag on the basis of Mg-Zn-Zr alloy, and the mass percentage of each component is: Zn is 3.0wt.%, Zr is 0.5wt.%, Ca is 0.3 wt.%, Ag is 0.1 wt.%, Mg is the balance, the content of single impurity elements such as iron, nickel, copper, aluminum is less than 0.05%, and the total content of various impurities is not more than 0.4% .

[0038] The preparation method of the degradable magnesium alloy rod for internal fixation of fractures has the following steps:

[0039] 1) Add Mg, Zn and Mg-30 wt %Zr, Mg-30 wt %Sr and Mg-30 wt %Ag master alloys into the graphite crucible, and evacuate to 1×10 -2 Pa, pass in argon gas for protection, heat to 720°C and keep it warm for 20 minutes, then fully stir at a speed of 5r / s for 5 minutes and then start to cool down. After the temperature drops to 690°C, pour it into the crystallizer, and take it out when it cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com